How to Design a Preform Mould

Aug 26,2022

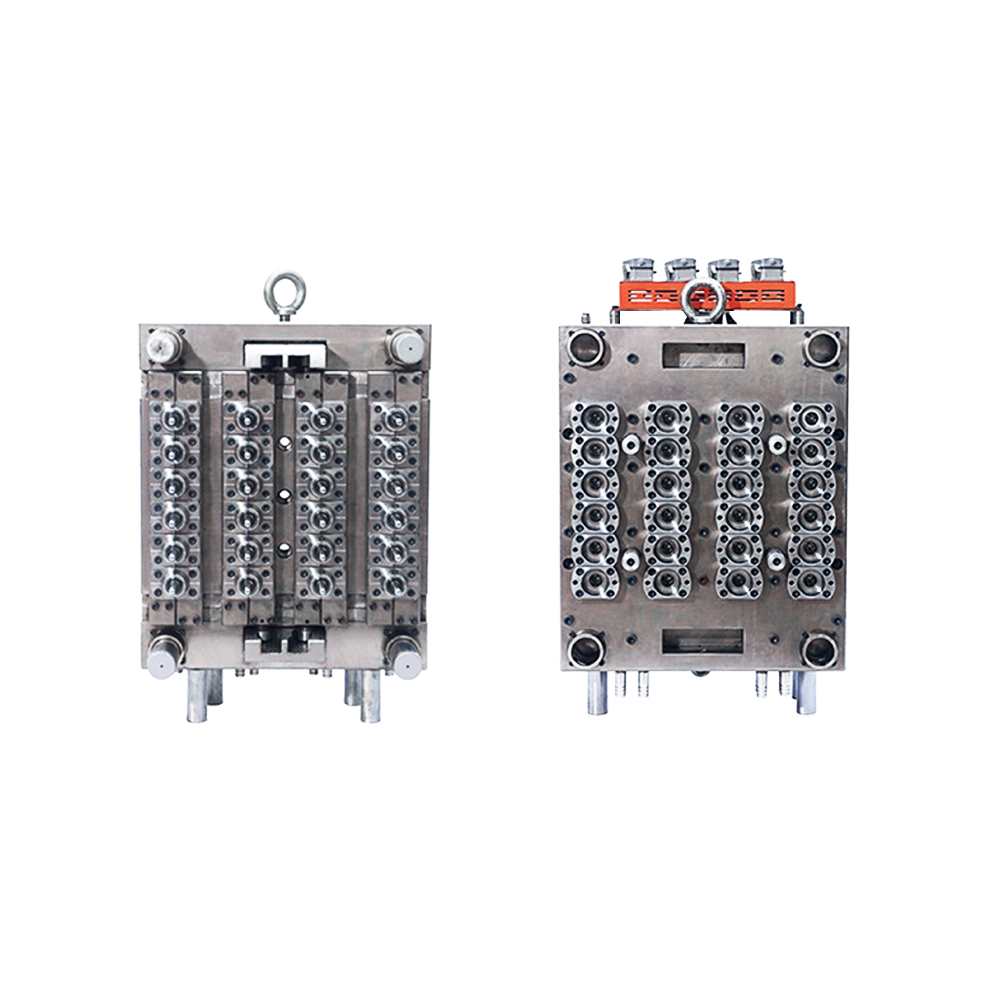

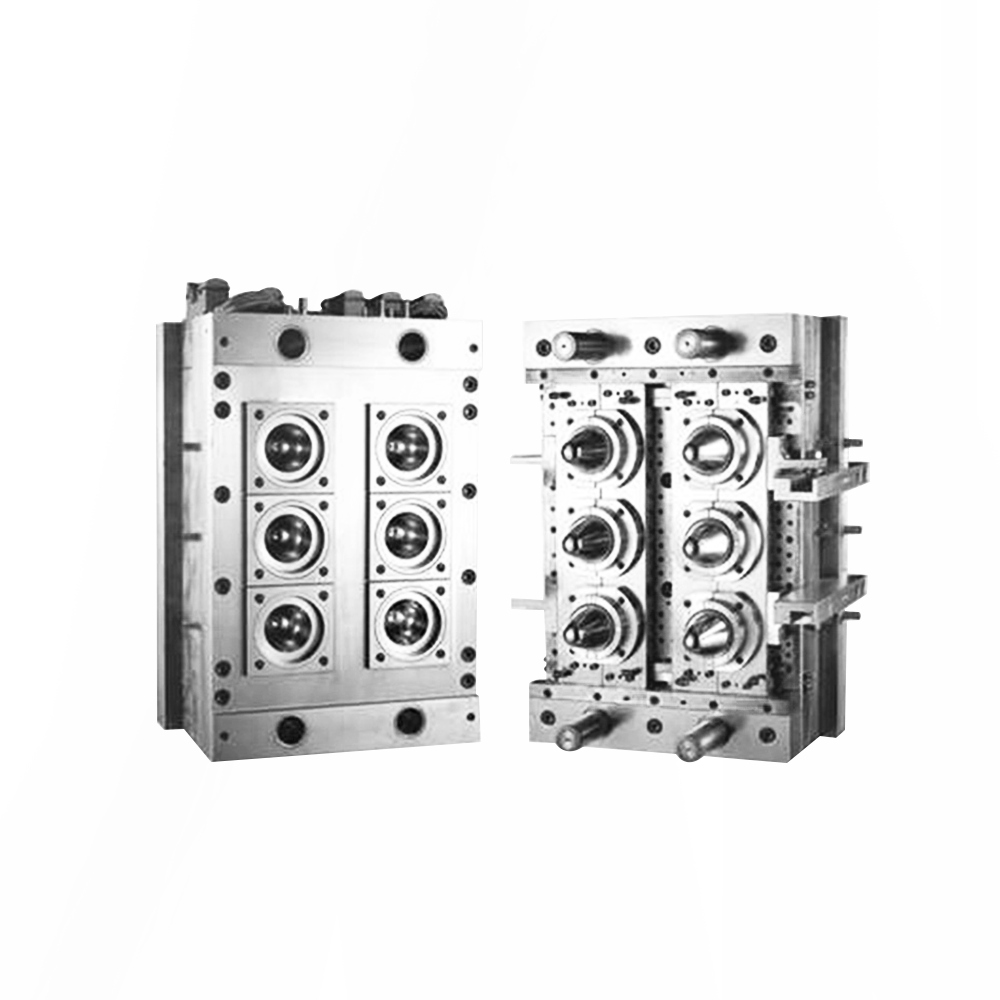

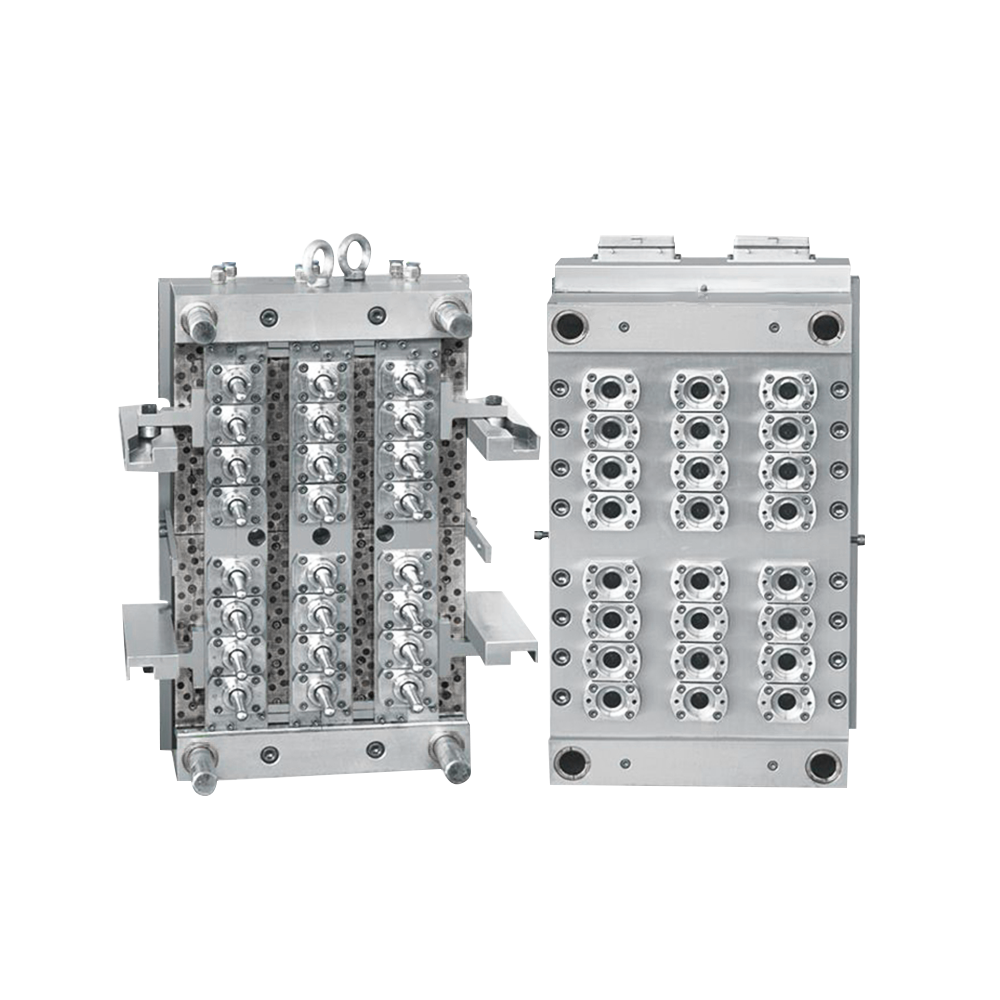

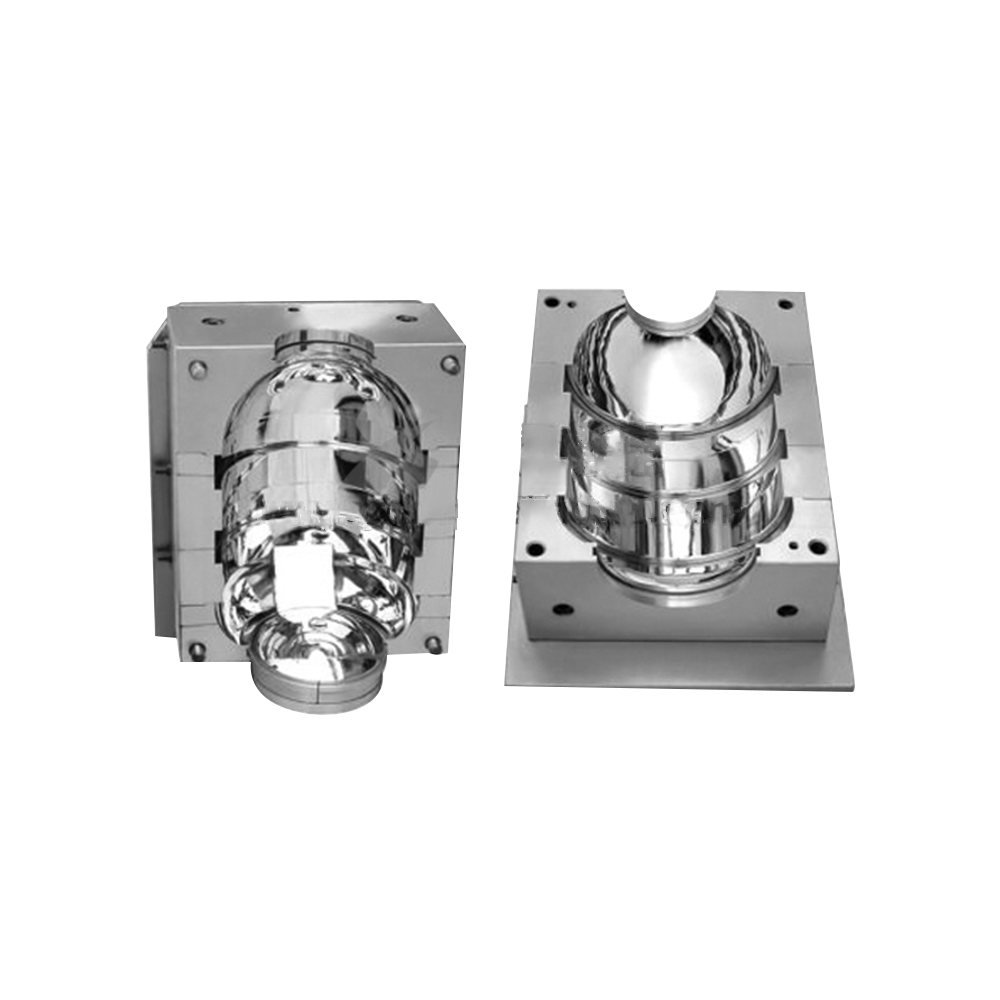

The design of a plastics PET preform mould should take into account the specific requirements of the customer. It should include details such as the materials used in the moulding process, the method for mounting the mould in a press, and the provision for temperature control. In addition, finishing tools such as gages, drill jigs, and buffing attachments should be considered. These tools must ensure accuracy of the finished product.

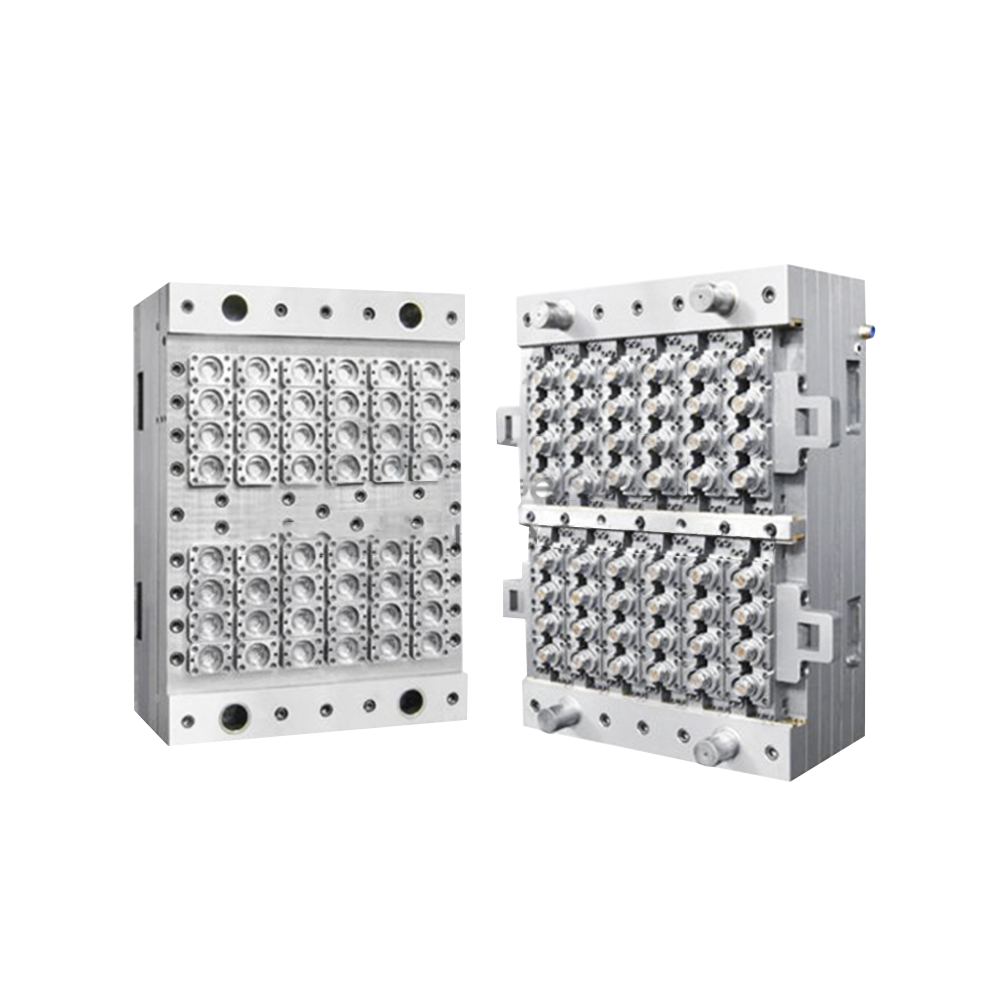

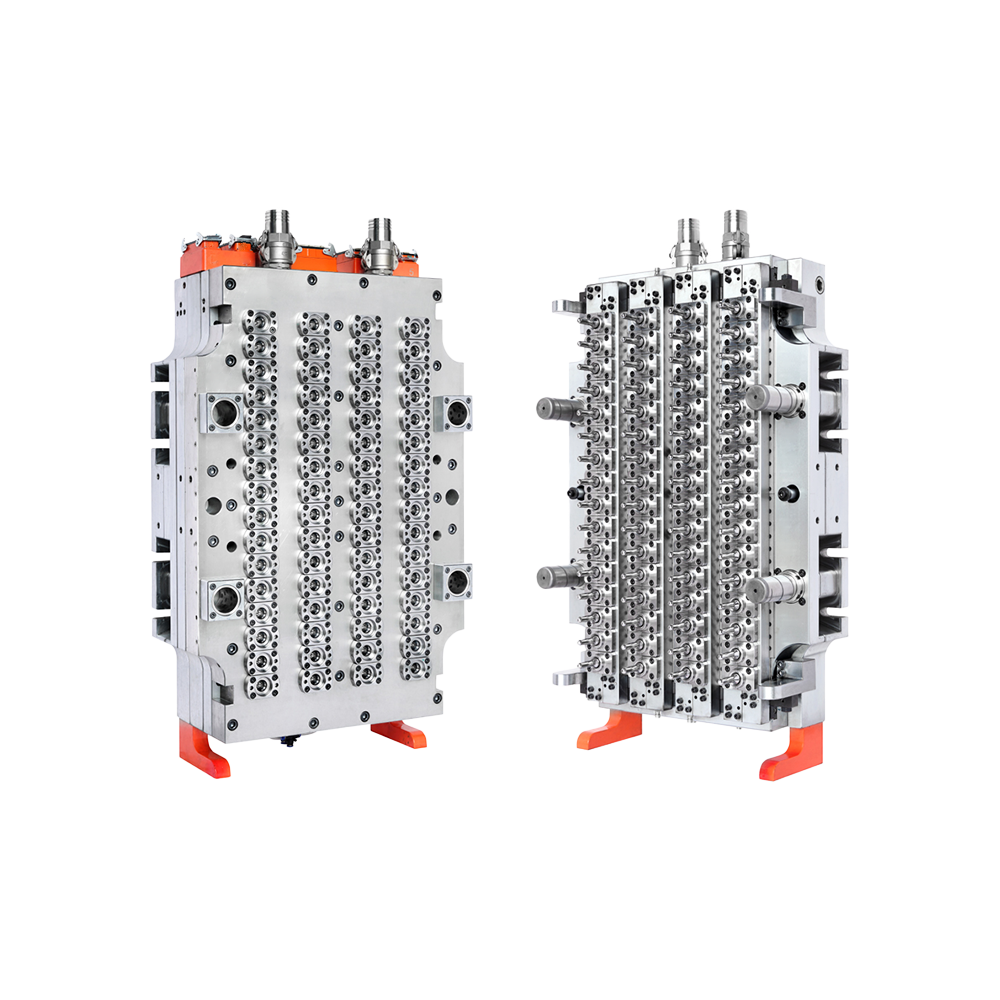

A preform mould that has the correct steel composition and processes is essential for a successful production. Specially designed water channels help reduce overall cycle times and minimize jamming. A Pin-valve Hot Runner System can also be used to minimize the amount of electricity used and reduce part wear. The Sigler molding system also has modular components that make it possible to accommodate a variety of preform lengths. The Sigler moulding system also reduces the tooling cost by minimizing the number of parts to replace.

Another factor to consider is the cooling capacity of the mold. The water should be cold enough to allow the preform to shrink away from the cavity. Depending on the type of preform, the preform might have to be cooled for a minimum of 1.5 seconds and as much as 20 seconds. In addition to maintaining the correct temperature, it is also important to maintain the right air pressure inside the mold.

English

English عربى

عربى Español

Español