| Lock way |

Double self-lock |

| Preform neck |

mm |

| Preform weight |

g |

| Core&cavity |

S136 |

| Cavity No. |

24 |

| Copper nozzle |

Material from Jiangxi |

| Heating plate |

P20 |

| Heater strip |

Import Germany |

| Sprue Runner |

H13 |

| Clinder,clinder cap,piston |

AL |

| Valve pin |

Punch(from Japan) |

| Insulation mat(cap) |

Dupont( from America) |

| Copper plate |

Material from Jiangsu |

| Heating ring |

Material from Guangdong |

| Reducing elbow |

Material from Guangdong |

| Temperature controller |

Material from Ningbo,Japan |

| Mould plate |

4Cr13/ P20 |

| Lifetime |

At least 2million Shots |

| Hardness |

HRC45-HRC48 |

| Slide block |

P20 |

| Heat block |

P20 |

| Exporter country standard voltage |

380V/3PH/50HZ |

| Packing |

1.Outside package:Standard wooden cases;2.Inner package: Stretch waterproof film & Each Mold painted anti-rust oil. |

| Delivery time |

Within 40 working days after prepayment |

| Term of Payment |

30% T/T deposit,70% T/T before delivery after confirmation of testing samples. |

| Guarantee |

1Year after-sale service.If the mould is damaged without artifical damage,Engineers available to service machinery overseas |

| Test parameters and videos will be sent when testing the mould. |

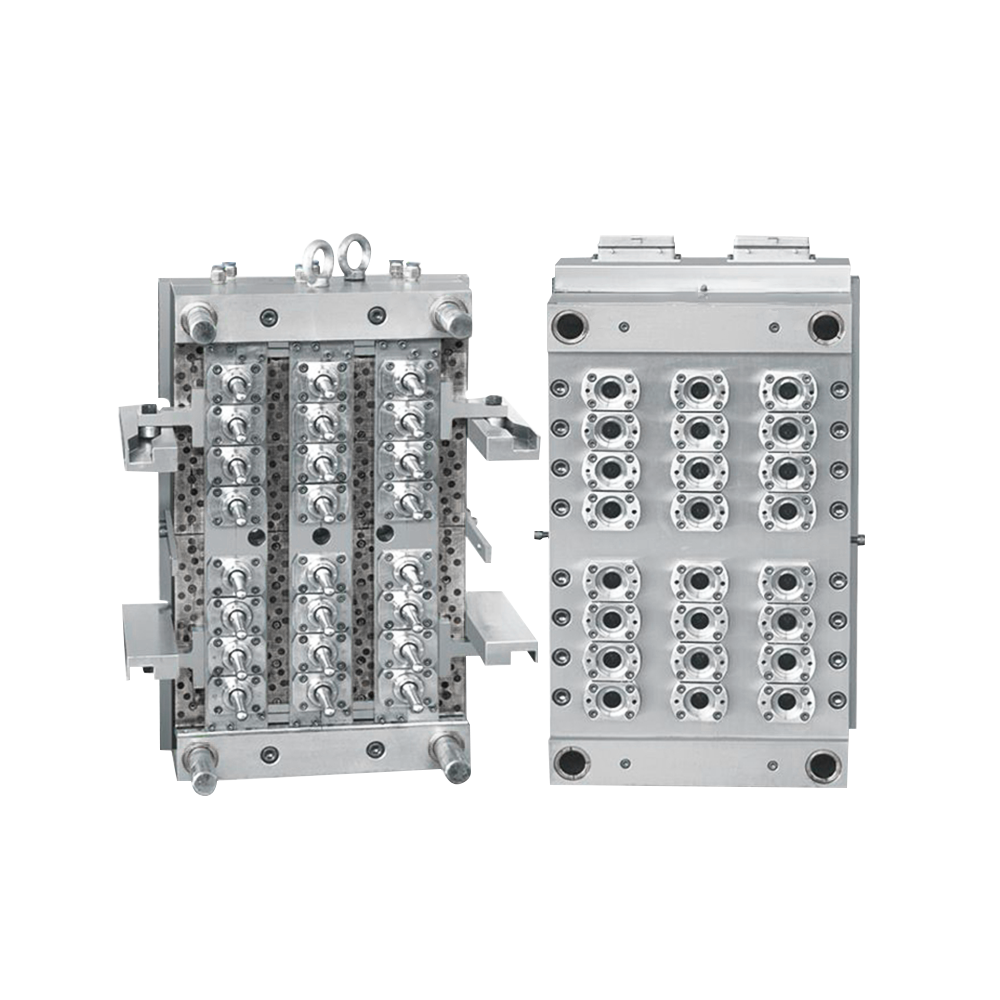

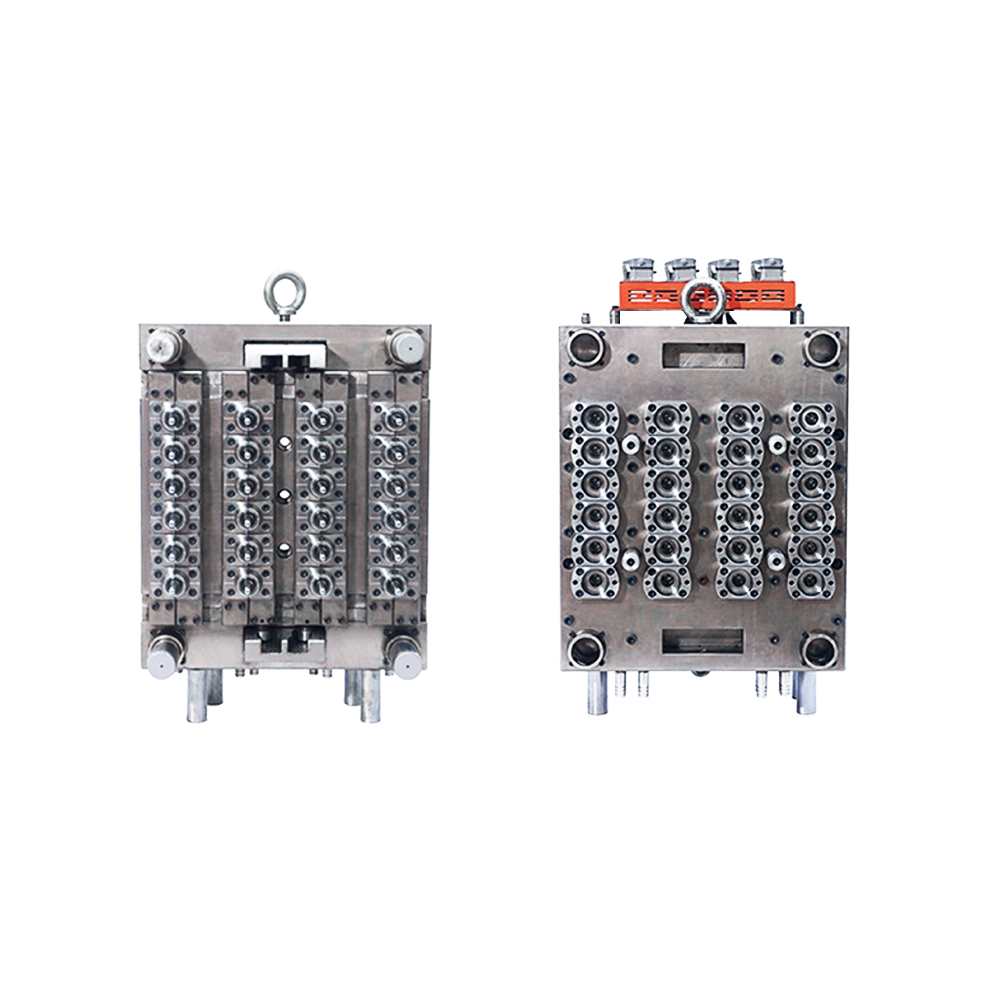

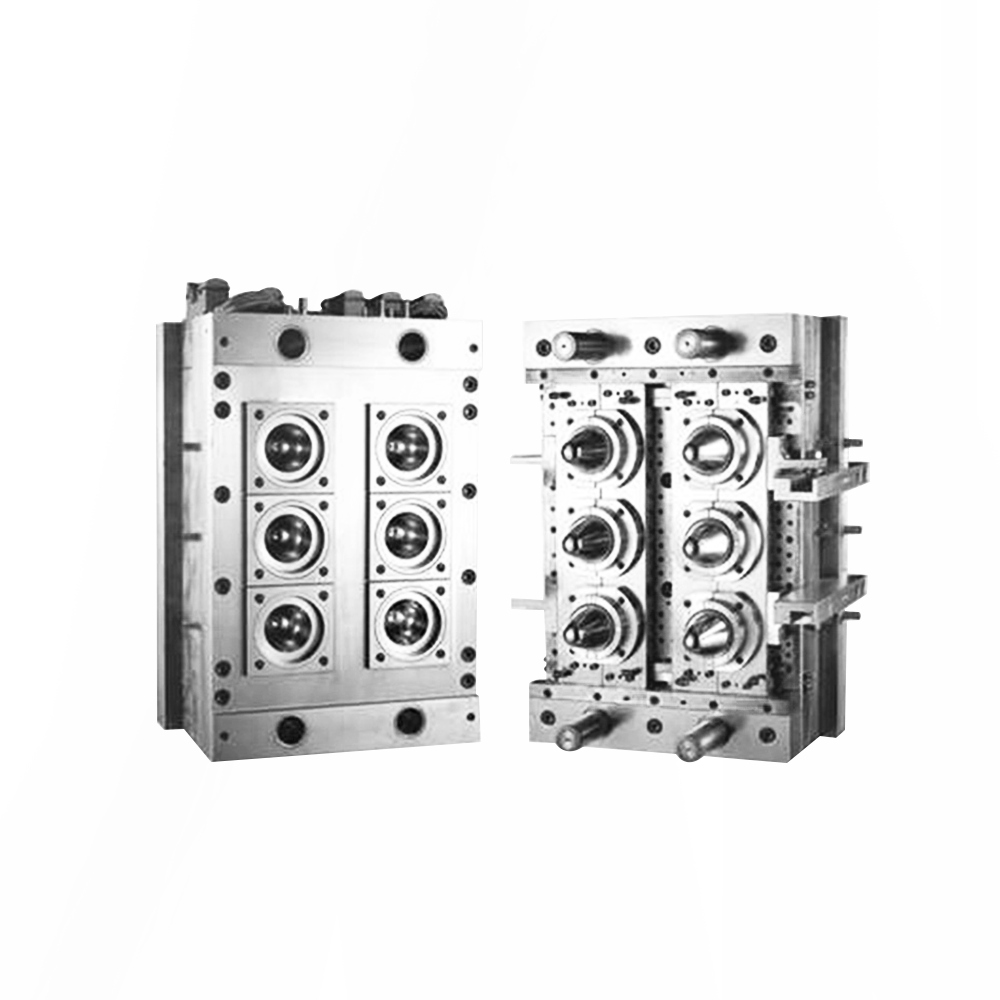

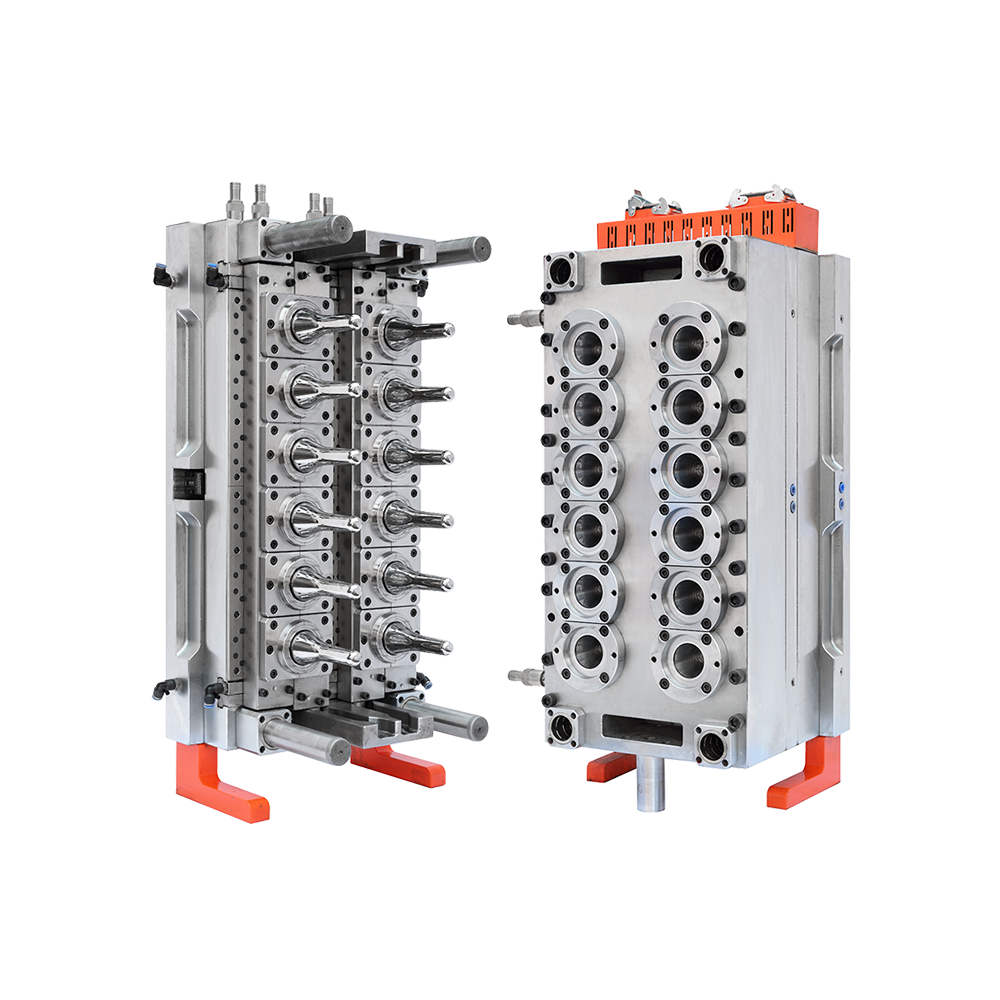

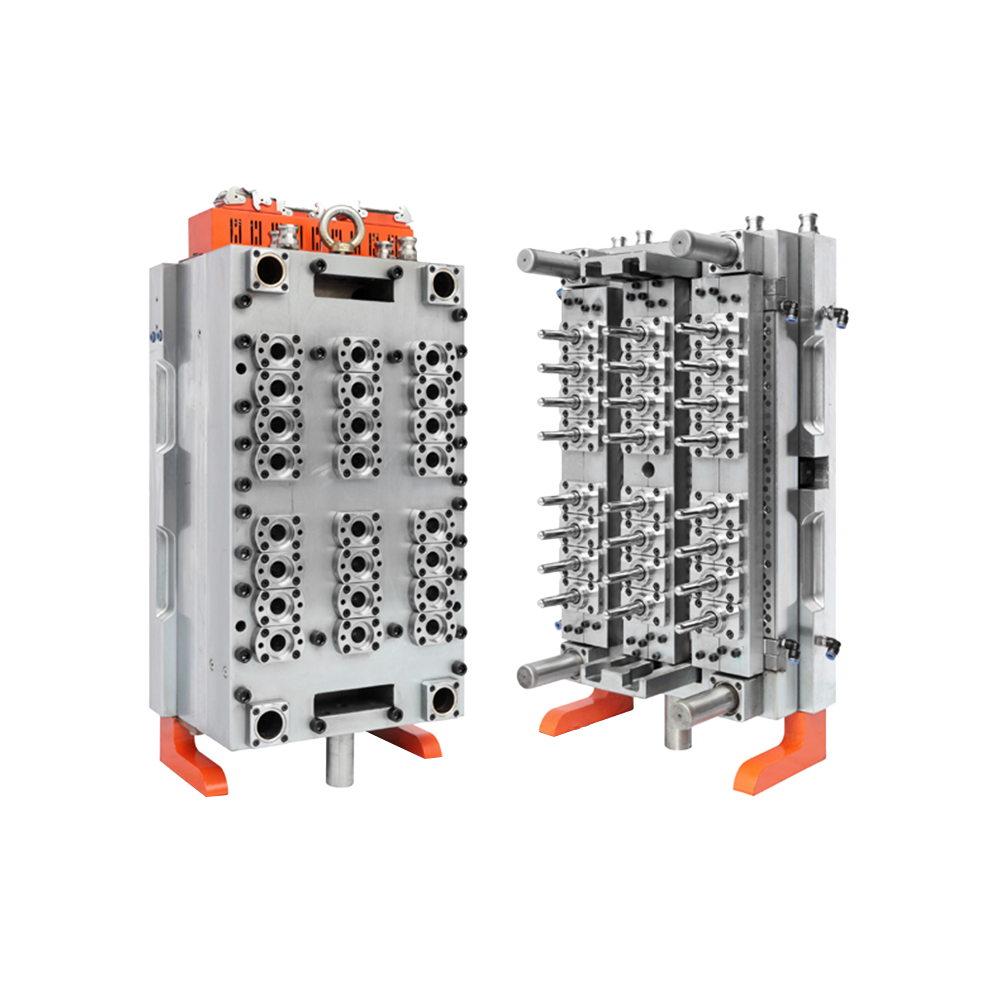

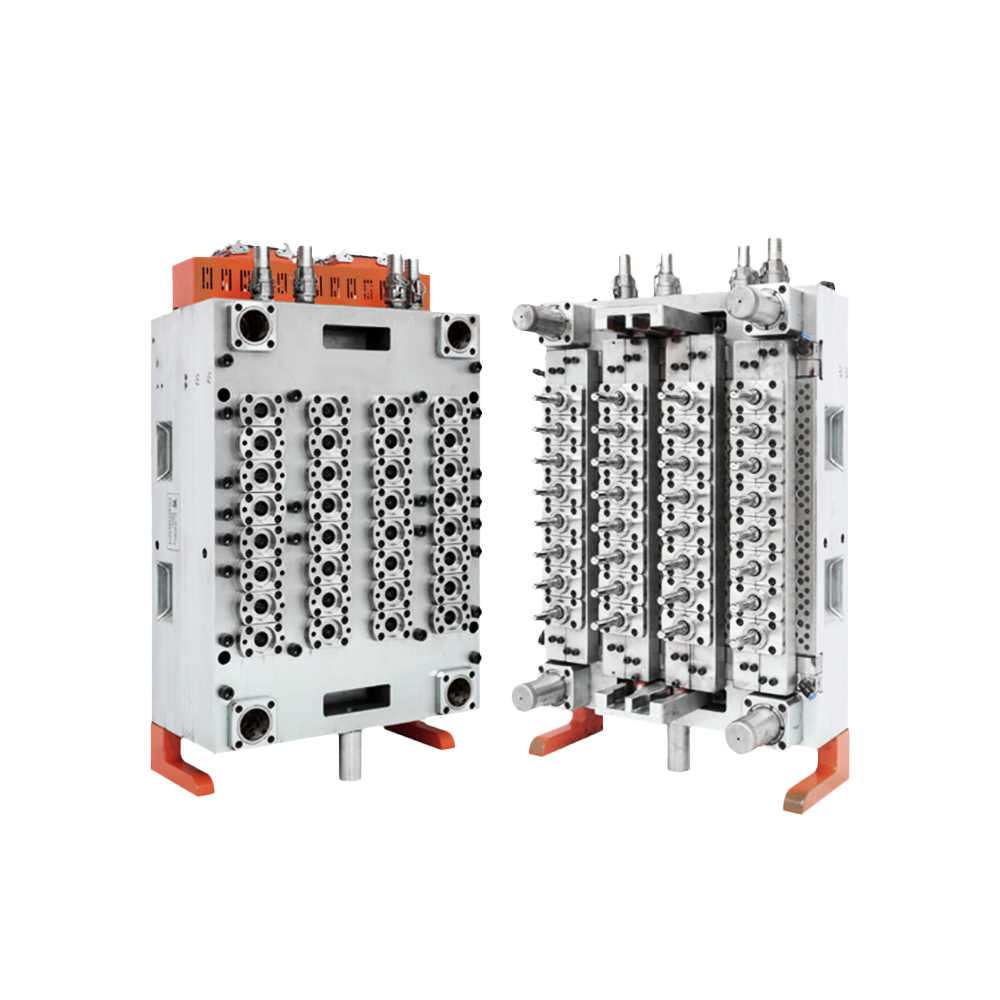

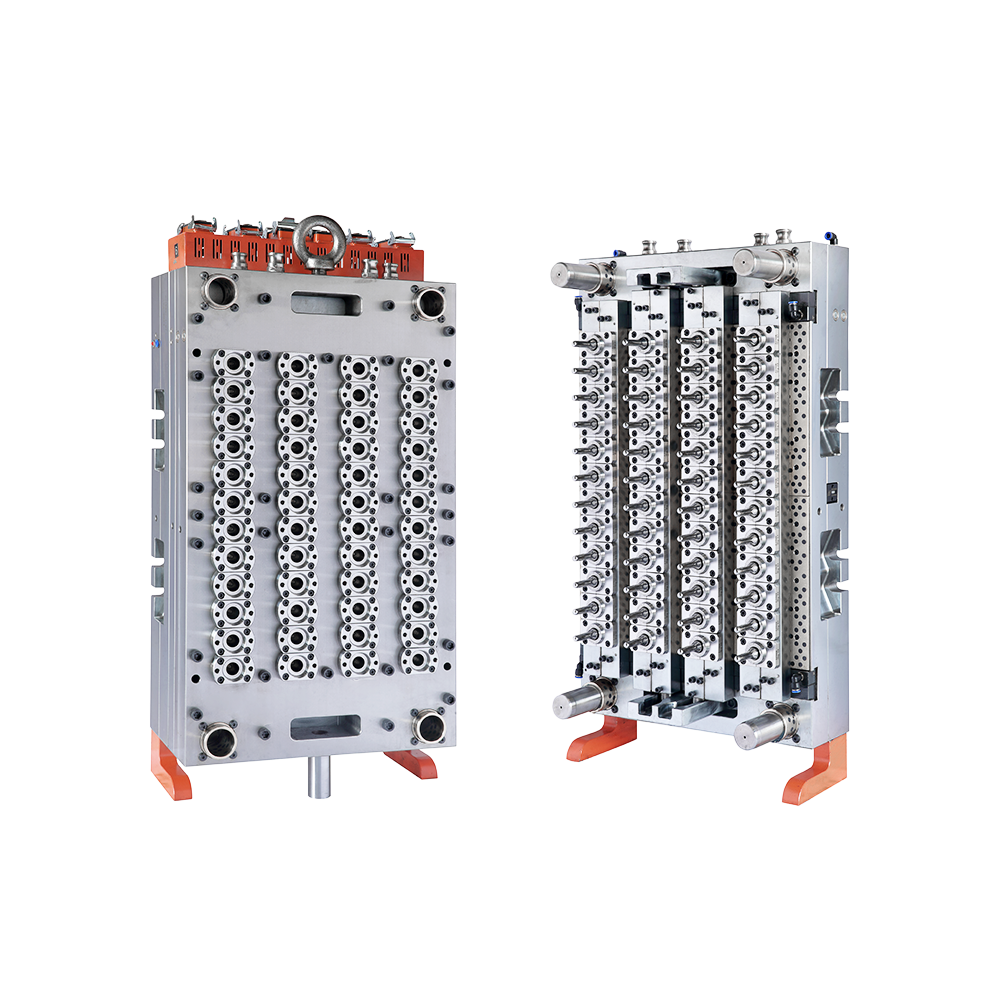

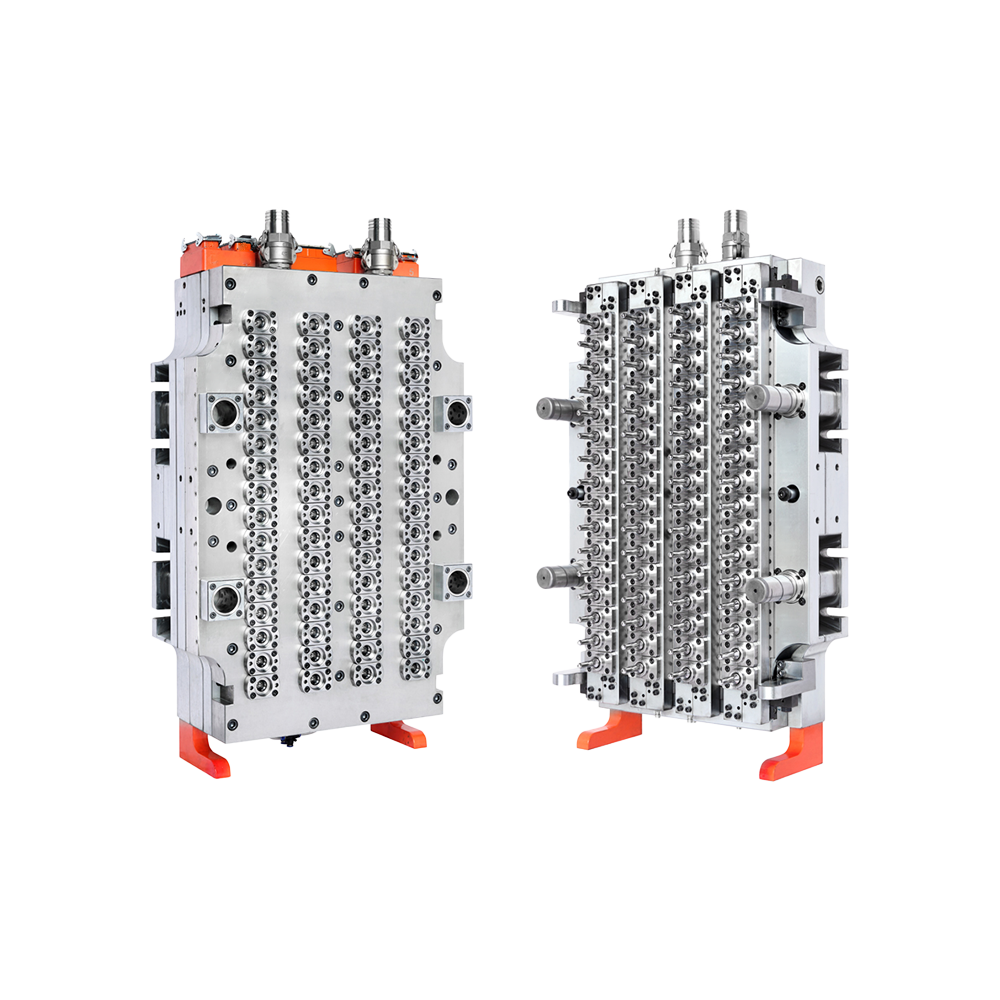

Cosmetic Preform Mould Suppliers, Cosmetic Preform Mould Manufacturers The cosmetic preform moulding has been exported to USA, UK and other European countries. it is welcomed by many customers because of its excellent performance and high quality. If you are interested in the cosmetic preform moulding or have any questions about our products, please do not hesitate to contact us.

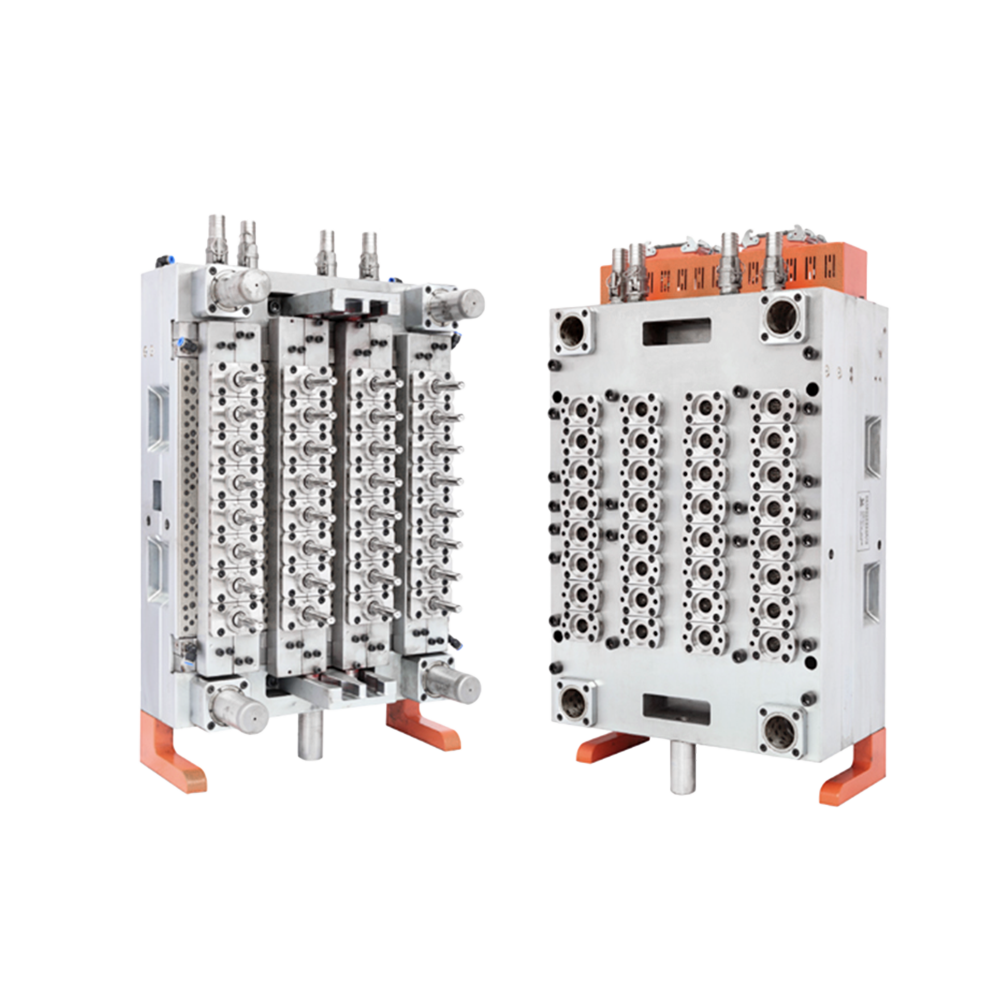

Cosmetic Preform Mould is used to manufacture preforms for hair and cosmetic bottles. We have experienced moldmakers and engineers who make sure that each mould we produced has high quality and its performance features are stable in long time production.

The cosmetic preform moulds are used in cosmetic injection moulding, the mould cavity is very complex,there are a few parts you need to care: 1, Use a long-term high temperature resistant nozzle 2.Use medium grade mold plate ( P20 )to make sure the plastic flow smoothly and strong parts strength 3.Processed by imported environmental friendly gas sealing 4.Heat treatment process: post-heating process,die-fixing process,alloy recombination process 5.To ensure that polyester resin products keep high quality.

We are one of the best manufacturers of Cosmetic Preform Mould in China. We can produce moulds by injection and gravity casting at the same time & in accordance with customers' requirements.

English

English عربى

عربى Español

Español