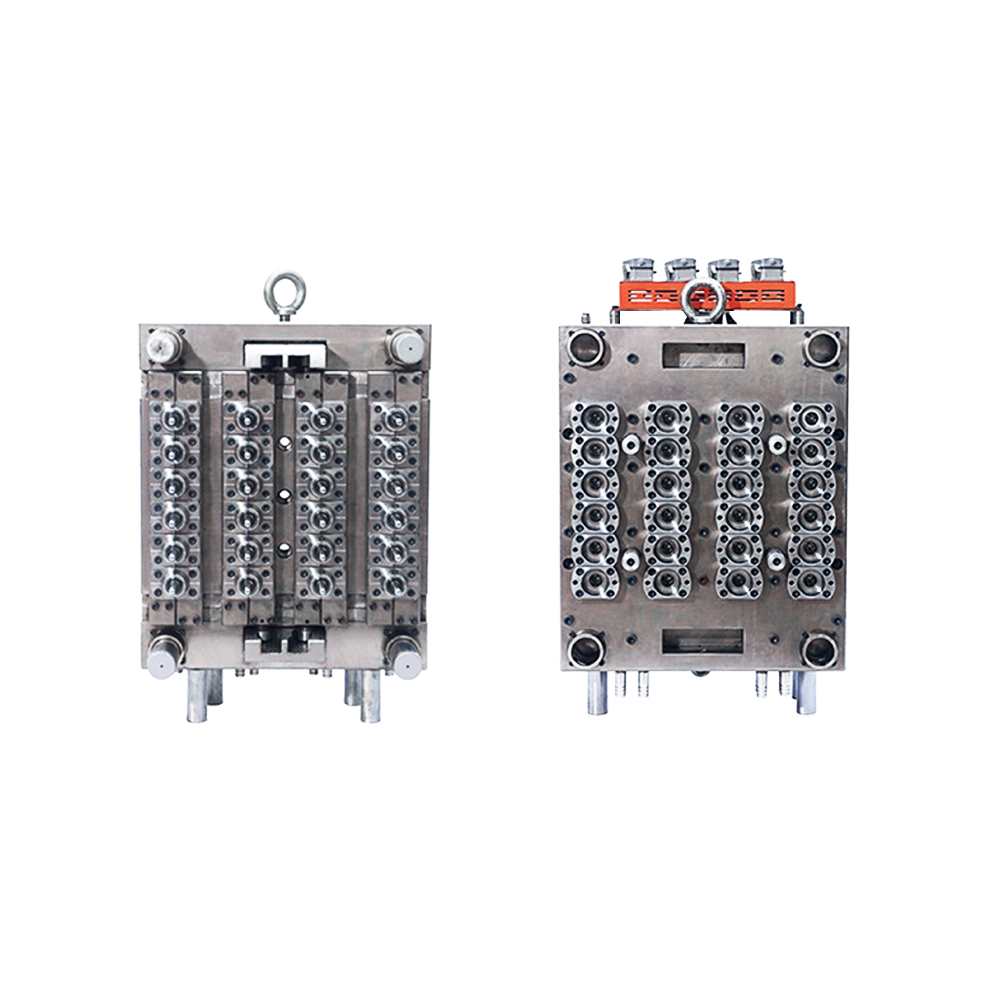

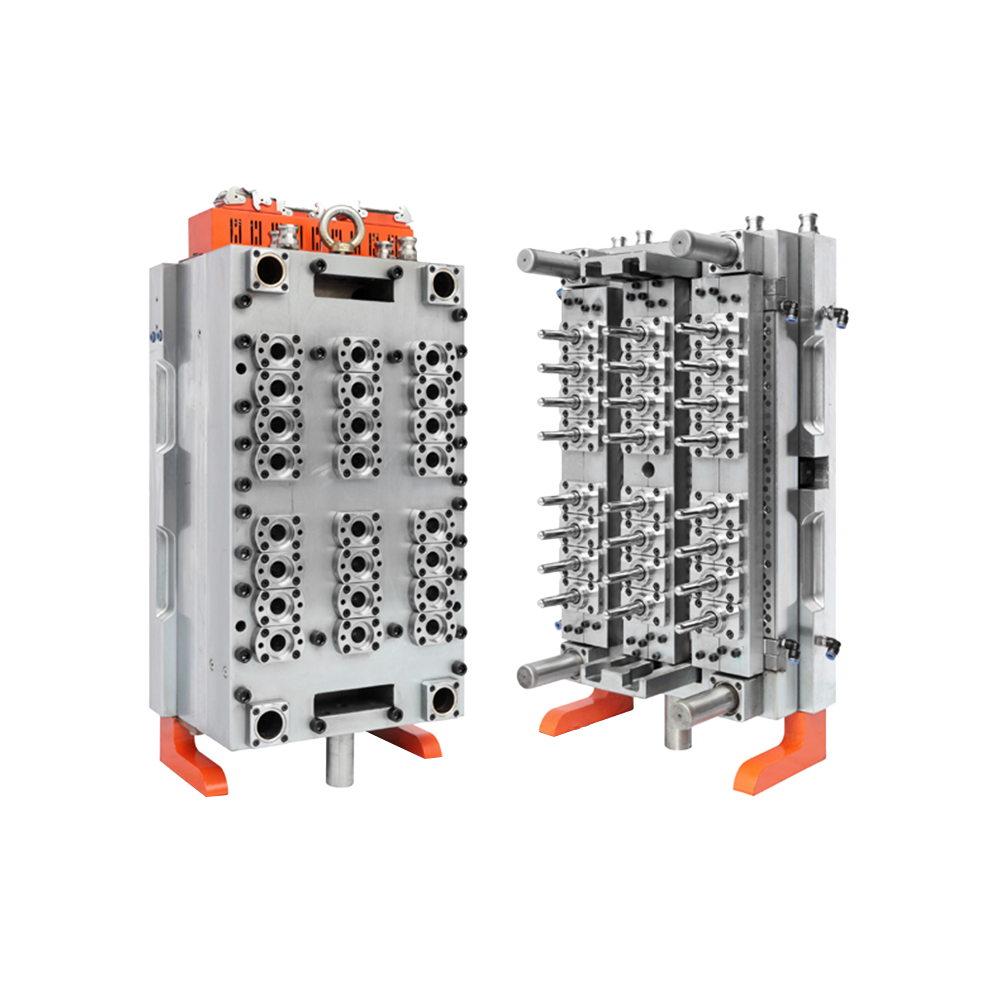

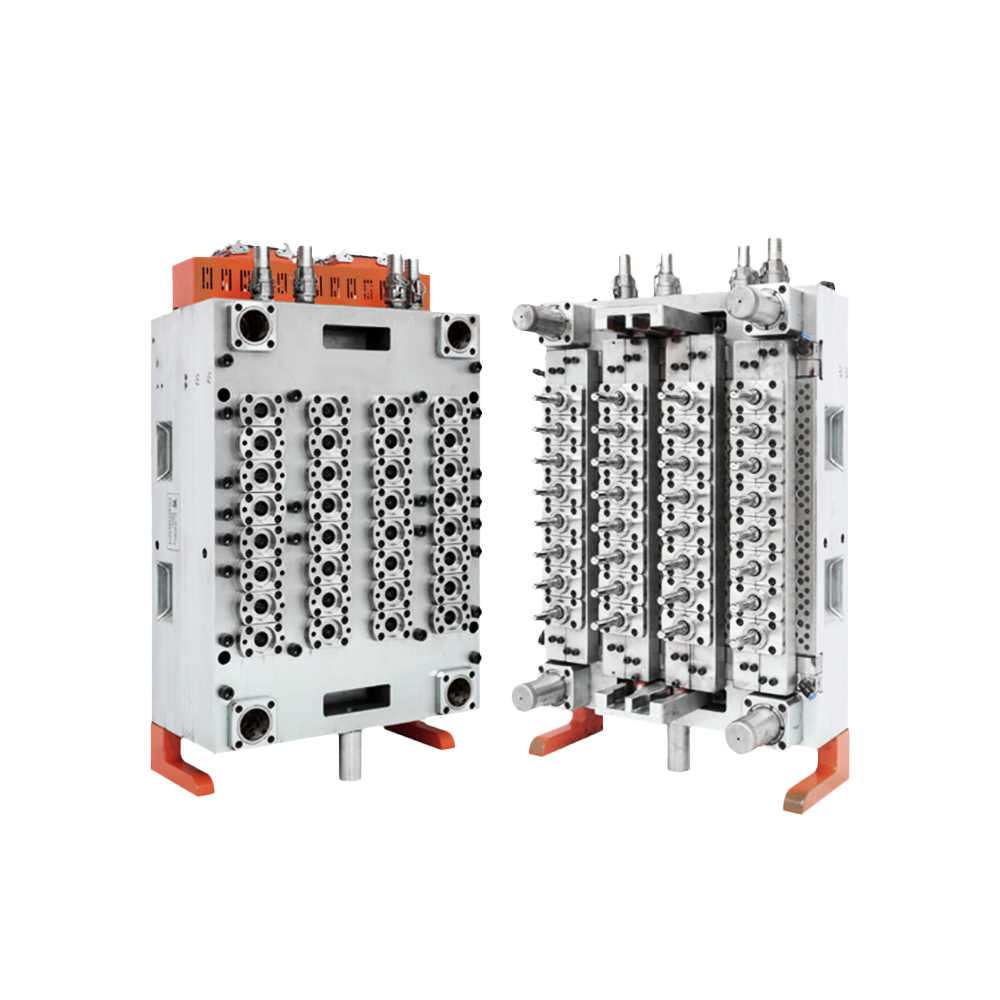

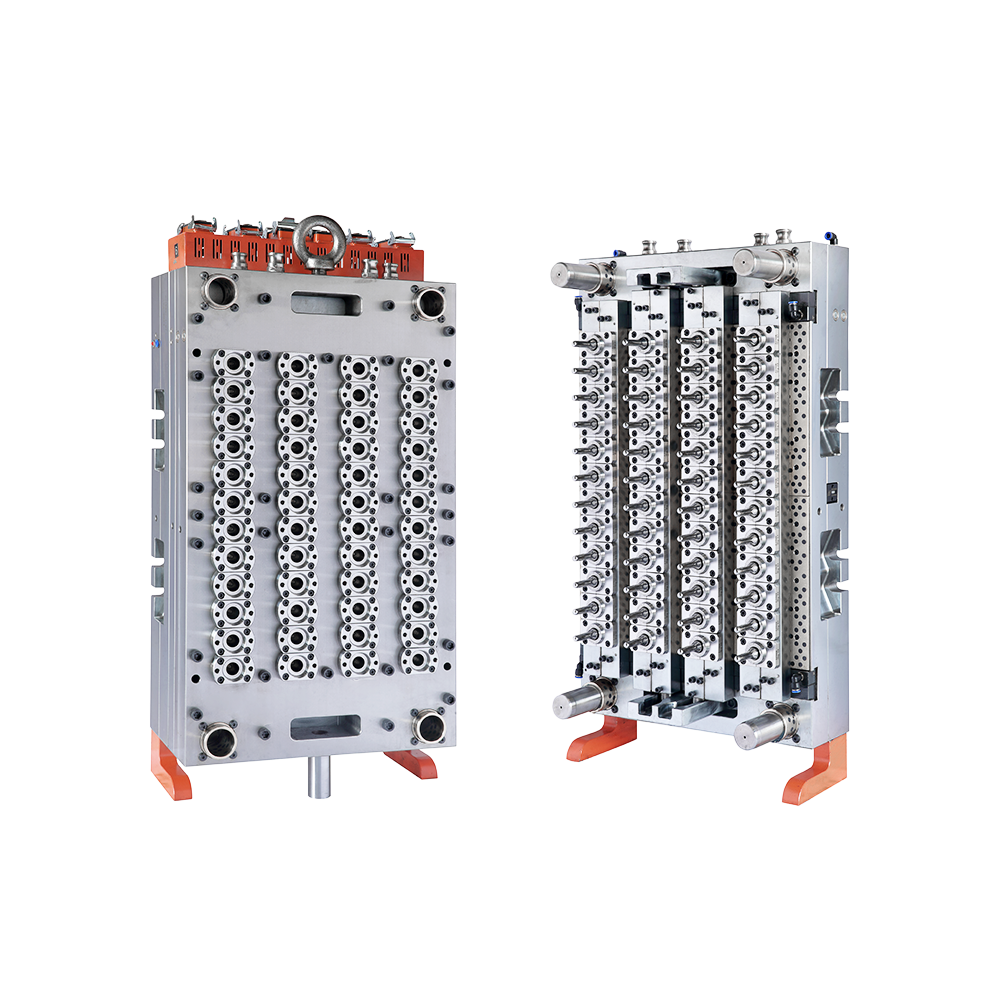

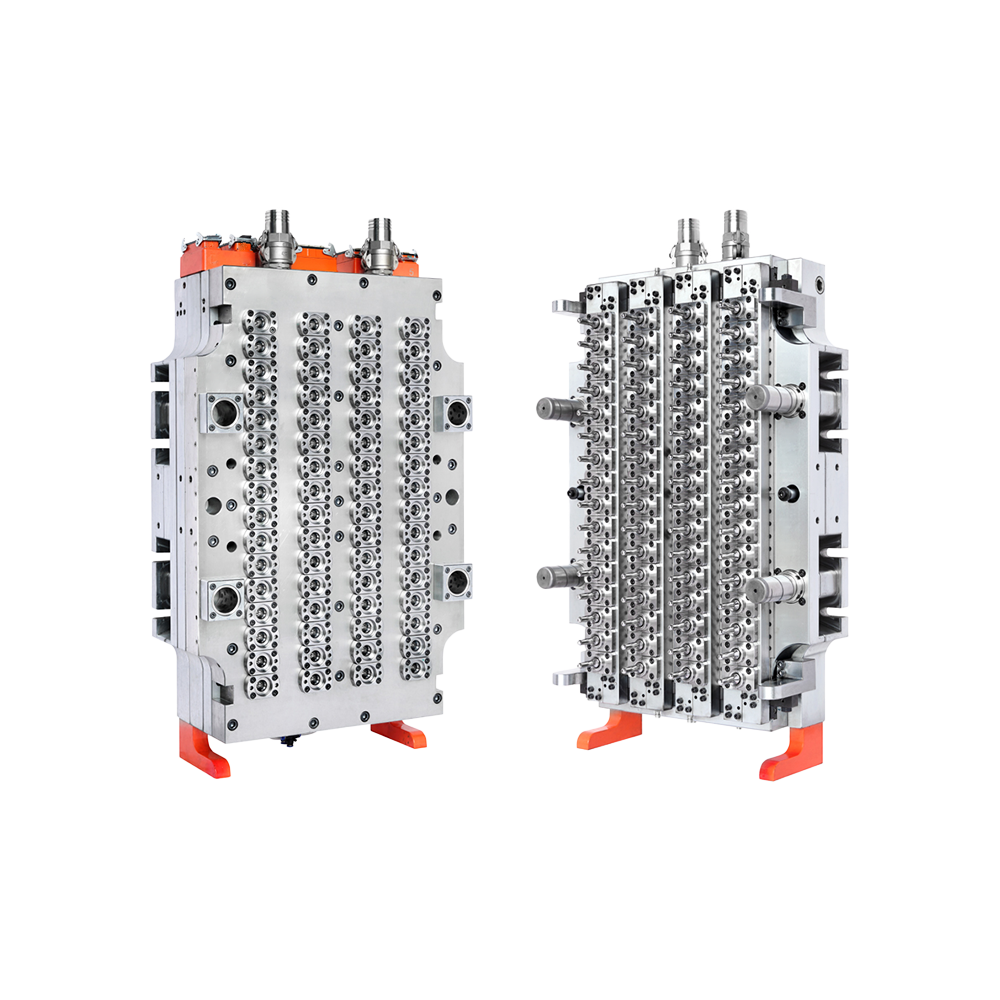

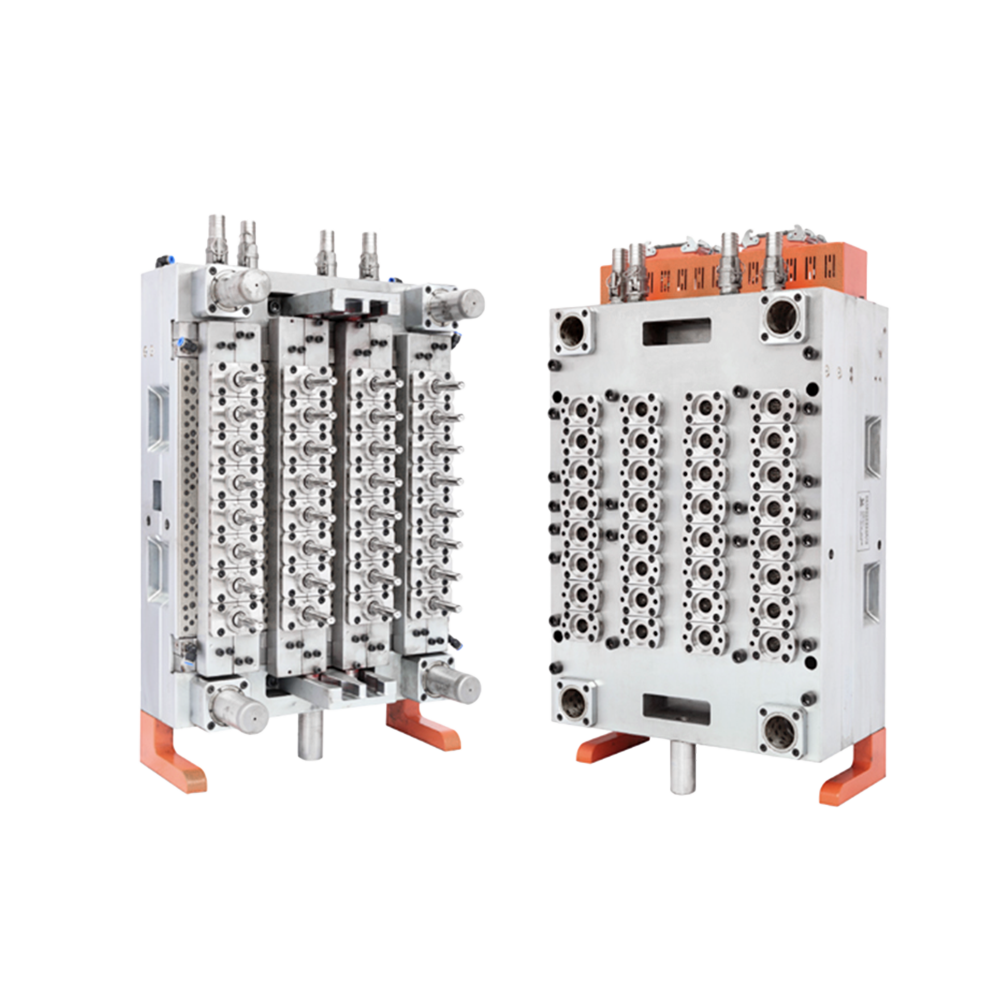

| Lock way |

Double self-lock |

| Preform neck |

52mm |

| Preform weight |

9g |

| Core&cavity |

S136 |

| Cavity No. |

48 |

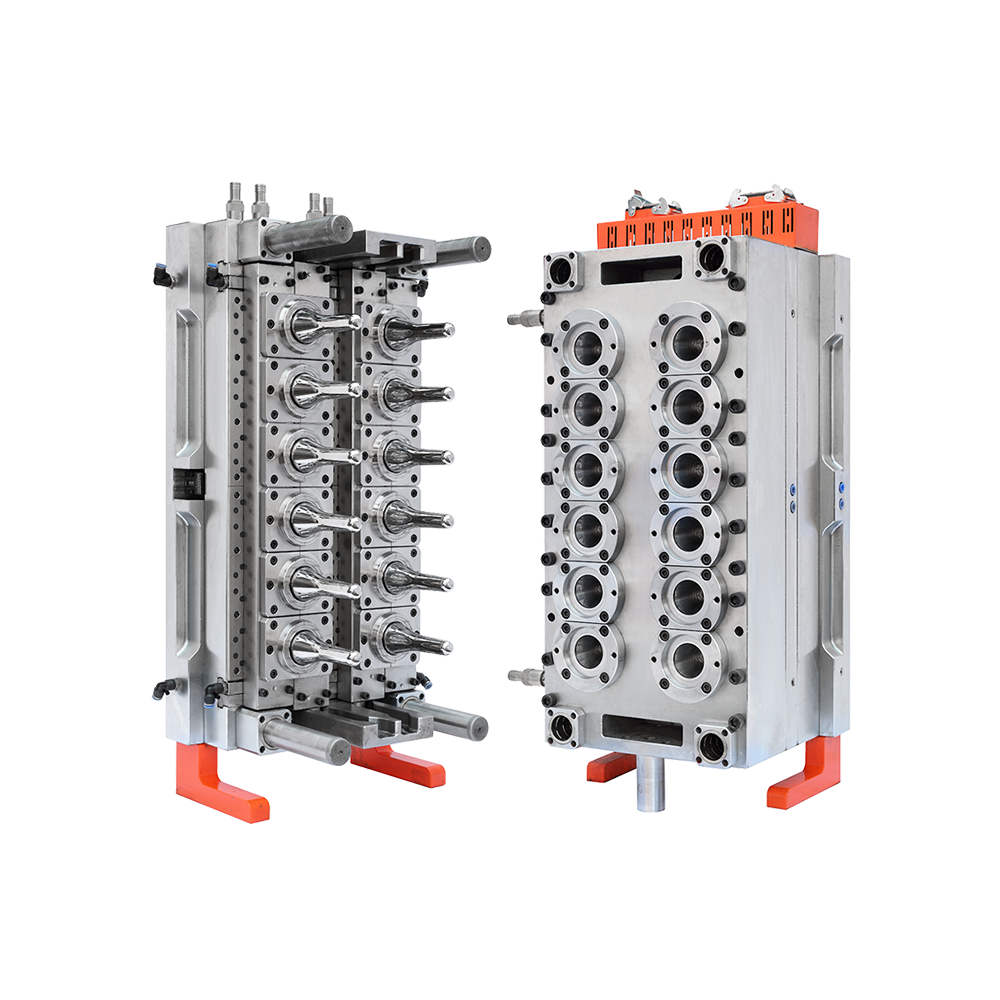

| Copper nozzle |

Material from Jiangxi |

| Heating plate |

P20 |

| Heater strip |

Import Germany |

| Sprue Runner |

H13 |

| Clinder,clinder cap,piston |

AL |

| Valve pin |

Punch(from Japan) |

| Insulation mat(cap) |

Dupont( from America) |

| Copper plate |

Material from Jiangsu |

| Heating ring |

Material from Guangdong |

| Reducing elbow |

Material from Guangdong |

| Temperature controller |

Material from Ningbo,Japan |

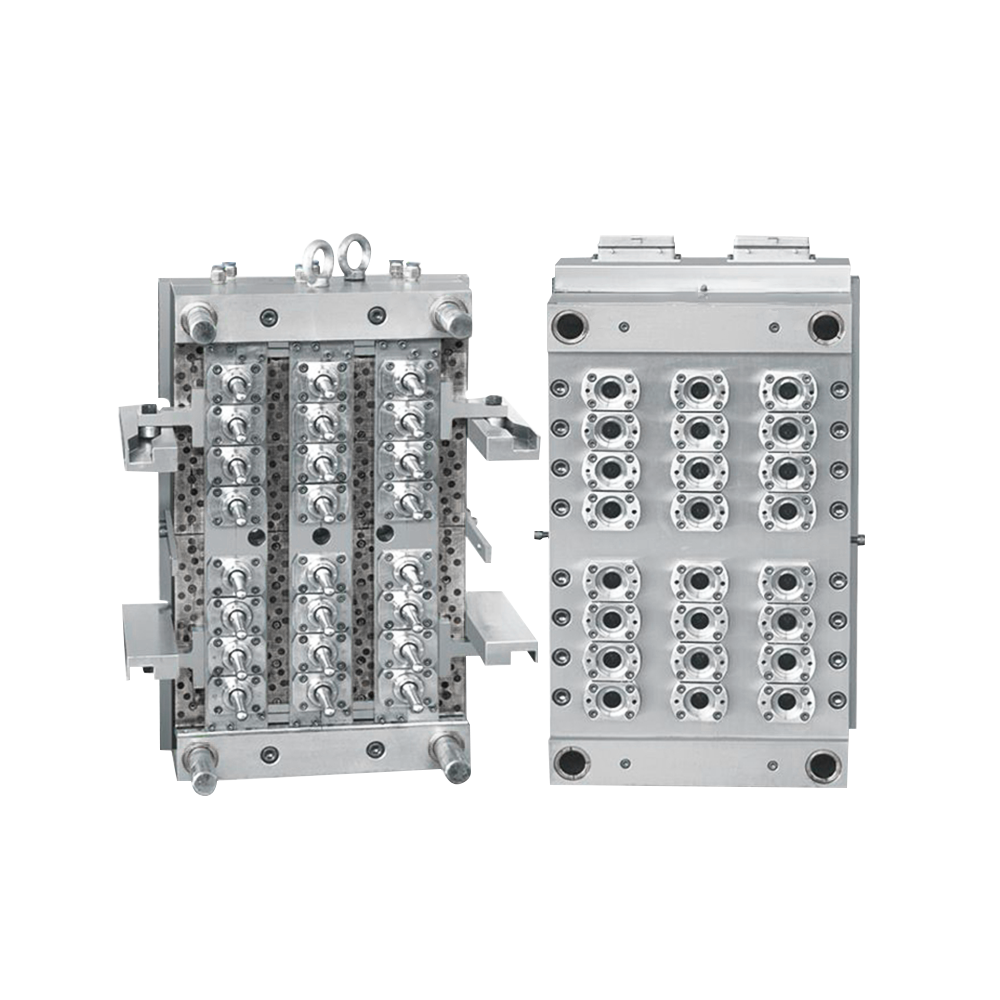

| Mould plate |

4Cr13/ P20 |

| Lifetime |

At least 2million Shots |

| Hardness |

HRC45-HRC48 |

| Slide block |

P20 |

| Heat block |

P20 |

| Exporter country standard voltage |

380V/3PH/50HZ |

| Packing |

1.Outside package:Standard wooden cases;2.Inner package: Stretch waterproof film & Each Mold painted anti-rust oil. |

| Delivery time |

Within 40 working days after prepayment |

| Term of Payment |

30% T/T deposit,70% T/T before delivery after confirmation of testing samples. |

| Guarantee |

1Year after-sale service.If the mould is damaged without artifical damage,Engineers available to service machinery overseas |

| Test parameters and videos will be sent when testing the mould. |

we are manufacturer in mould,we can produce as per customers' requirement.We have advanced testing machine to check the quality of the mould.

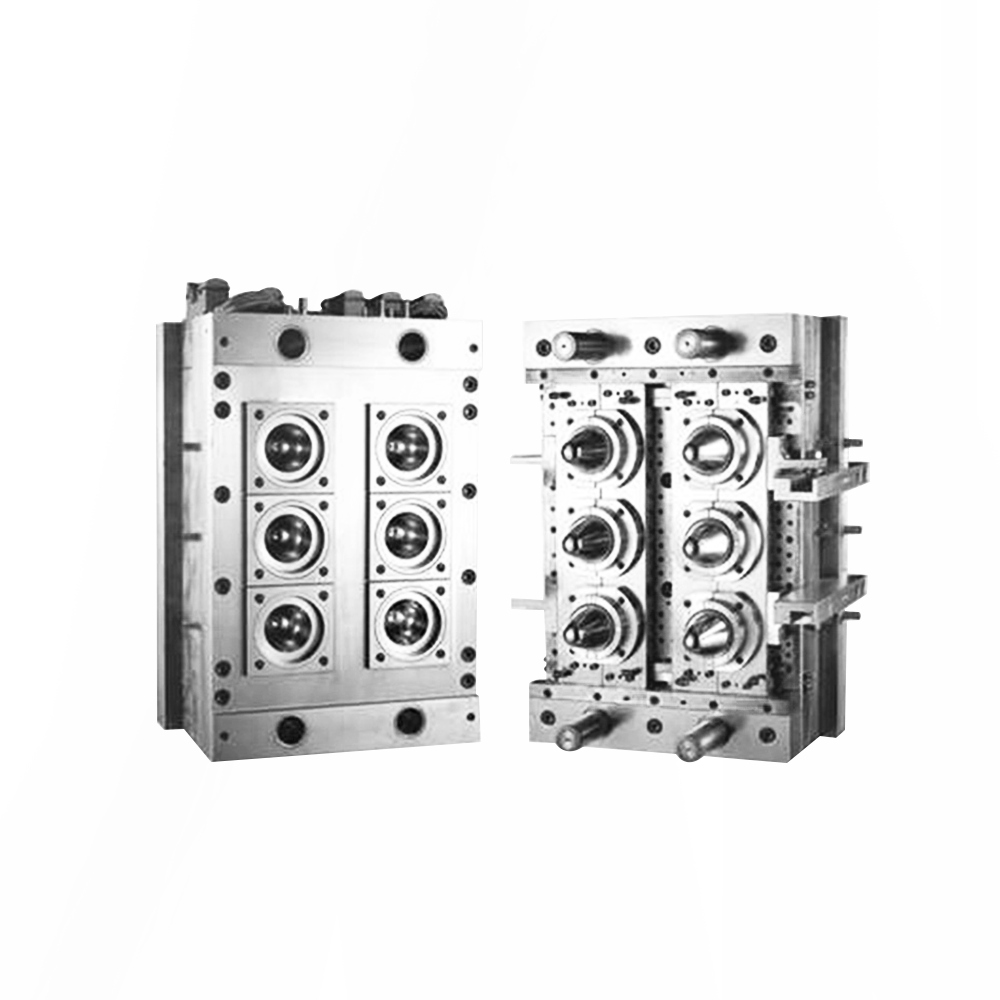

We are very good in producing PET preform mould and so on. We have many years experience of mould design and production,we have more than 200 moulds in different production lines,such as EPS mould and so on. We can provide all kinds of equipment for you as per your specific requirements. If you need any assistance about new product development or mould design services, please contact us!

Teflon mould materials is one of the best in sub chamber, but it has a very high thermal expansion coefficient and insulation resistance than steel. But our teflon mould material with very good performance.

This 52mm 9g zip-top can preform mould from cold chamber injection moulding machine is made of 4Cr13/P20 steel,hardness: HRC45-HRC48.It has double self-lock and a cavity of 48.The mould is exported by China to France and other countries.

The mould is made of high quality carbon steel or stainless steel.We have a strict selection and examination procedure,in order to improve the quality and stability of the product.

English

English عربى

عربى Español

Español