How to Install Preform Mould and The Application of Preform Mould

May 05,2023

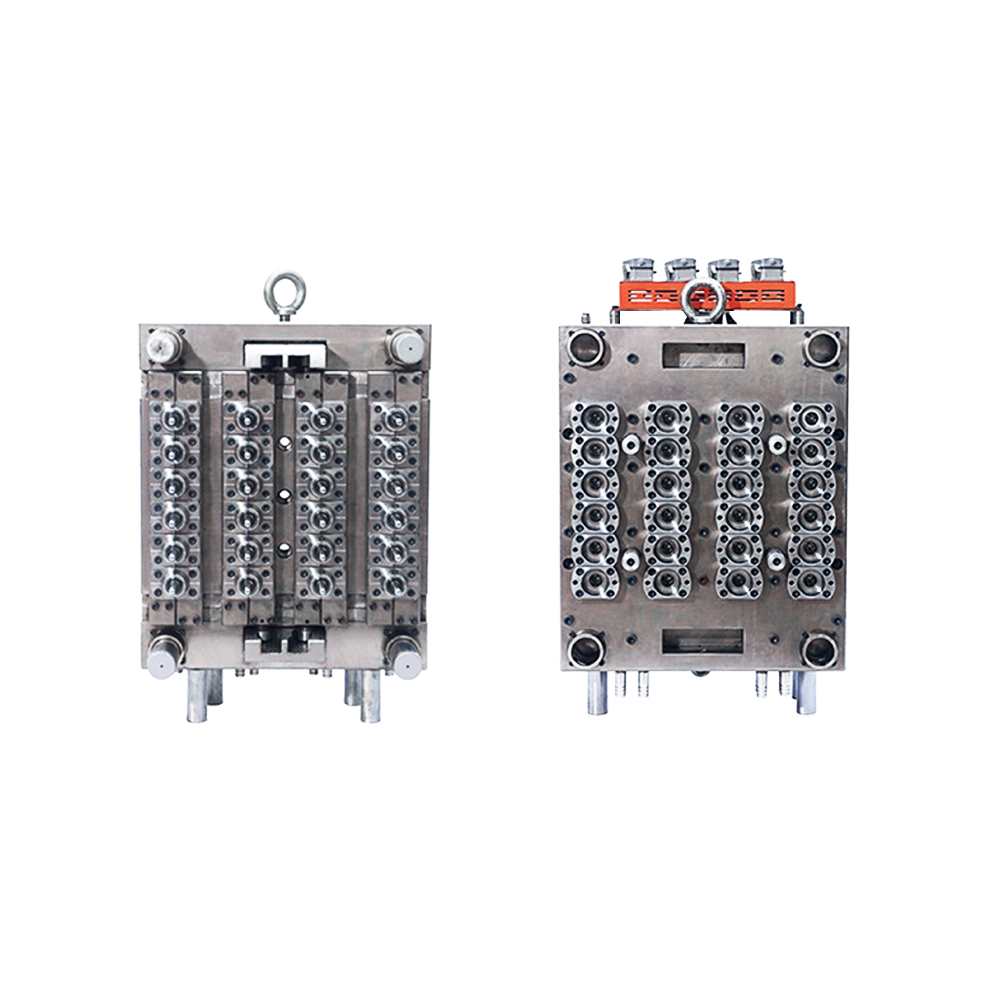

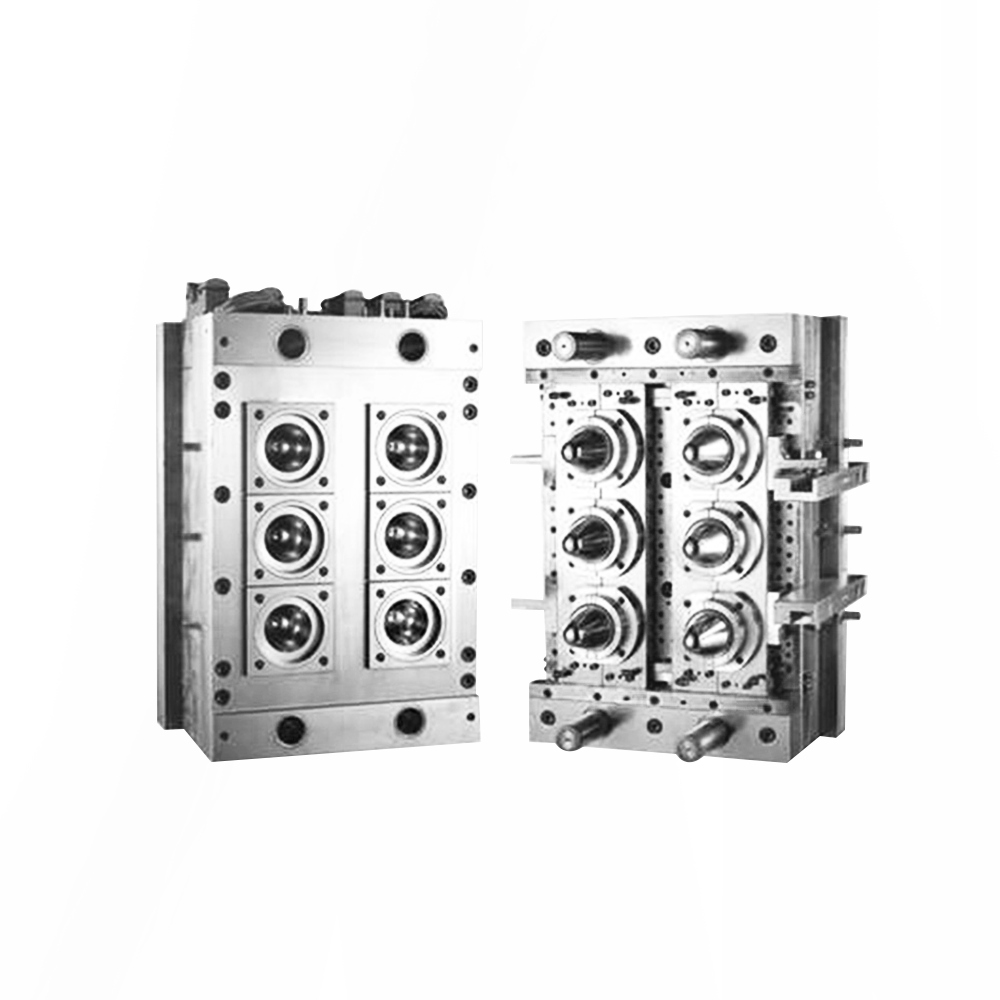

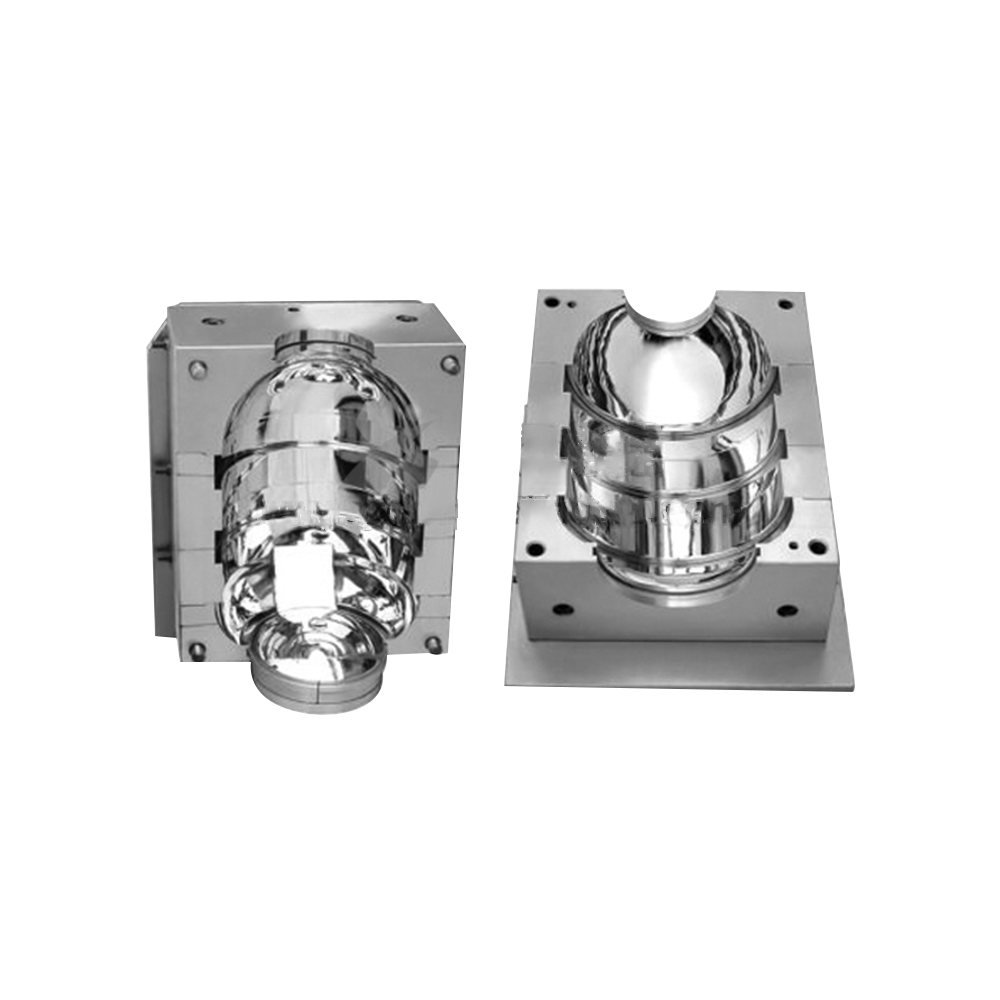

The installation of a preform mould will vary depending on the specific mould and machine being used. However, the following steps provide a general overview of the installation process:

Ensure the mould is clean and free of debris. Inspect the mould for any damage or defects.Install the mould onto the machine according to the manufacturer's instructions. This typically involves attaching the mould to the mould base and aligning it with the machine's injection unit.Adjust the mould height and centering, if necessary. The mould should be level and centered on the machine to ensure proper operation.Install the mould heaters and thermocouples. The heaters are used to heat the mould and the thermocouples are used to monitor the temperature.Connect the water lines to the mould cooling channels. The cooling channels help to regulate the temperature of the mould during operation.Test the mould for leaks and proper operation. Run a test cycle to ensure the mould is functioning correctly and that there are no leaks or other issues.Make any necessary adjustments to the mould or machine settings. This may involve adjusting the injection pressure, temperature, or cycle time to achieve the desired results.Once the mould is properly installed and tested, it is ready for production. Regular maintenance and cleaning of the mould can help to prolong its lifespan and ensure consistent production.

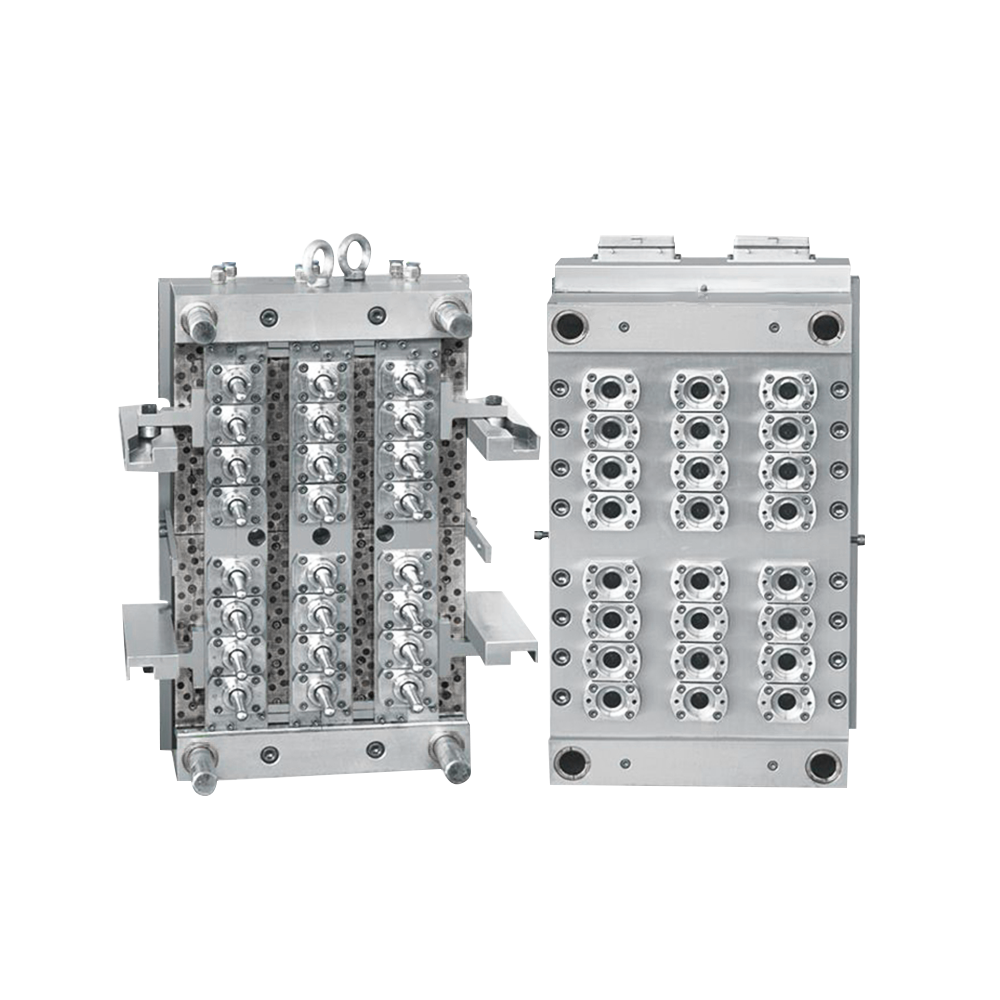

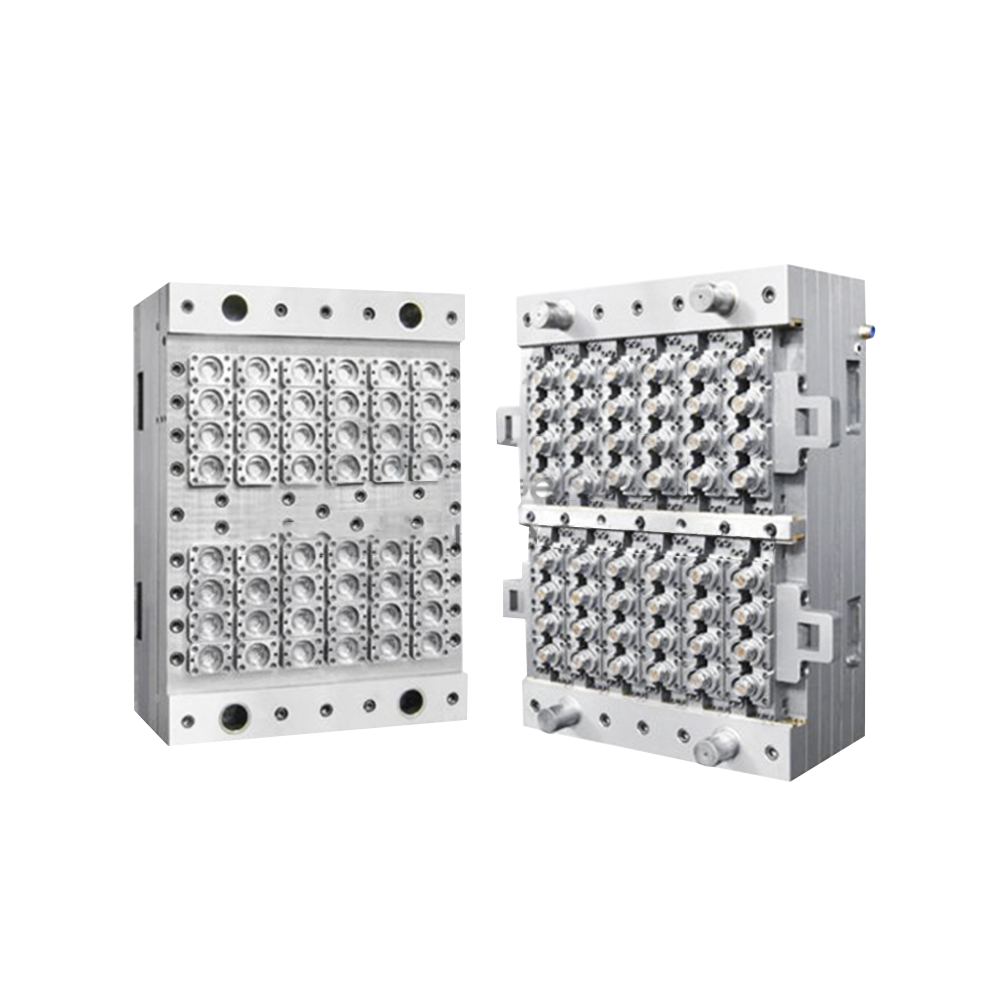

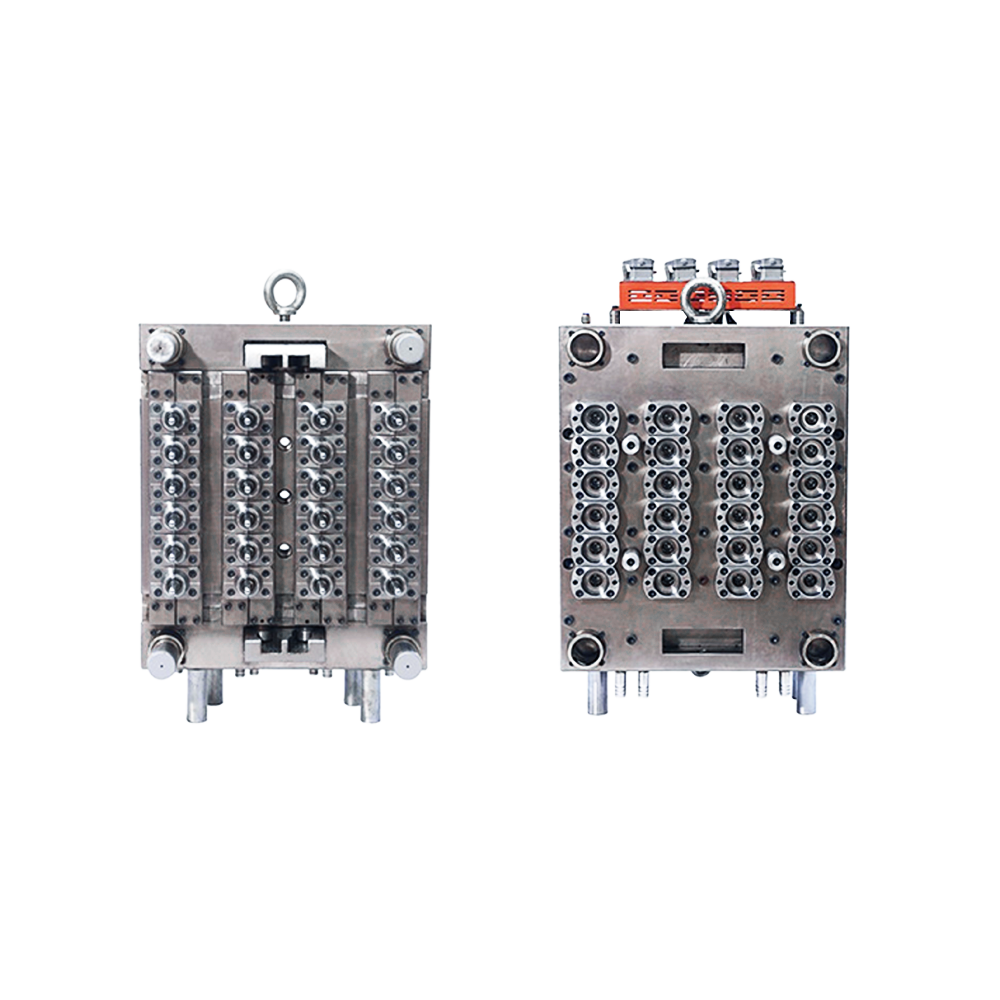

It is important to follow the manufacturer's instructions for installing and operating the preform mould to ensure safe and efficient operation. If you are unsure about any aspect of the installation process, consult with a qualified technician or contact the manufacturer for guidance.Meanwhile,Preform moulds are widely used in the manufacturing of plastic products, particularly in the production of PET bottles. PET preforms are commonly used as the starting material for the production of plastic bottles, jars, and containers. These preforms are heated and stretched to create the final shape of the bottle or container.

Here are some of the common applications of preform moulds:Beverage industry: Preform moulds are used to produce PET preforms for the beverage industry. PET bottles are lightweight and durable, making them an ideal choice for bottled water, soft drinks, and other beverages.Food industry: Preform moulds are used to produce PET containers for food products such as condiments, sauces, and snacks. PET containers are lightweight and shatterproof, making them a safer and more convenient option for food packaging.Personal care industry: Preform moulds are used to produce PET containers for personal care products such as shampoo, lotion, and soap. PET containers are resistant to moisture and chemicals, making them ideal for use in the personal care industry.Pharmaceutical industry: Preform moulds are used to produce PET containers for pharmaceutical products such as pills and capsules. PET containers are lightweight and tamper-evident, making them a secure and convenient option for pharmaceutical packaging.

Overall, preform moulds are an essential component of the plastic manufacturing industry. They allow for the production of high-quality PET preforms that can be used to create a wide range of plastic products for various industries.

English

English عربى

عربى Español

Español