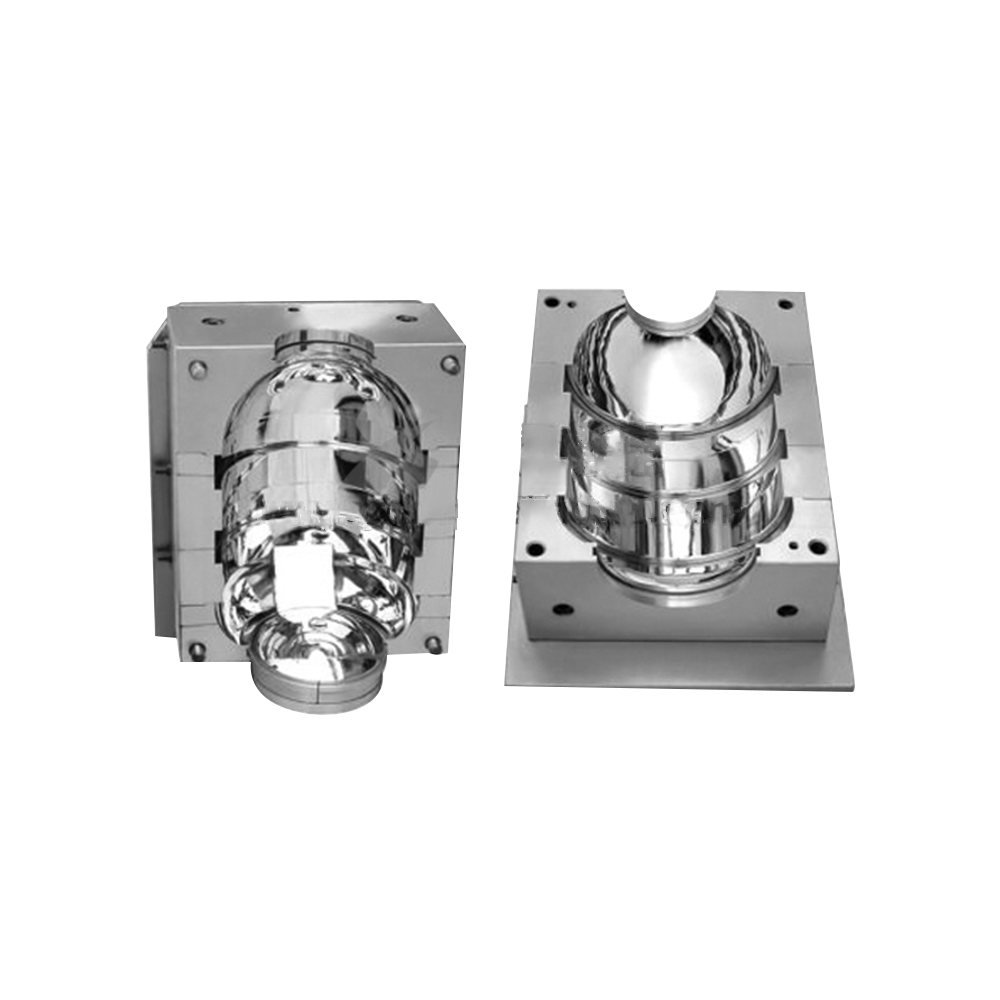

The benefits of preform injection mold custom

Feb 22,2023

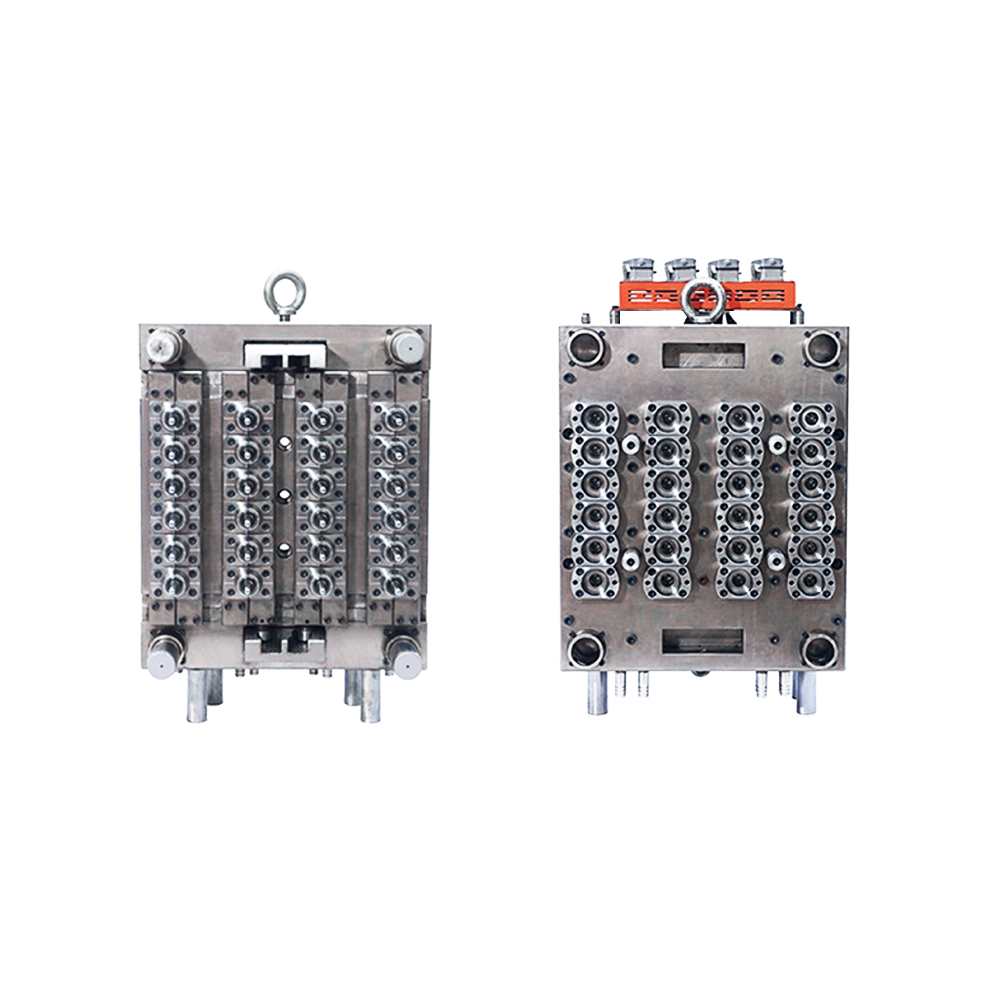

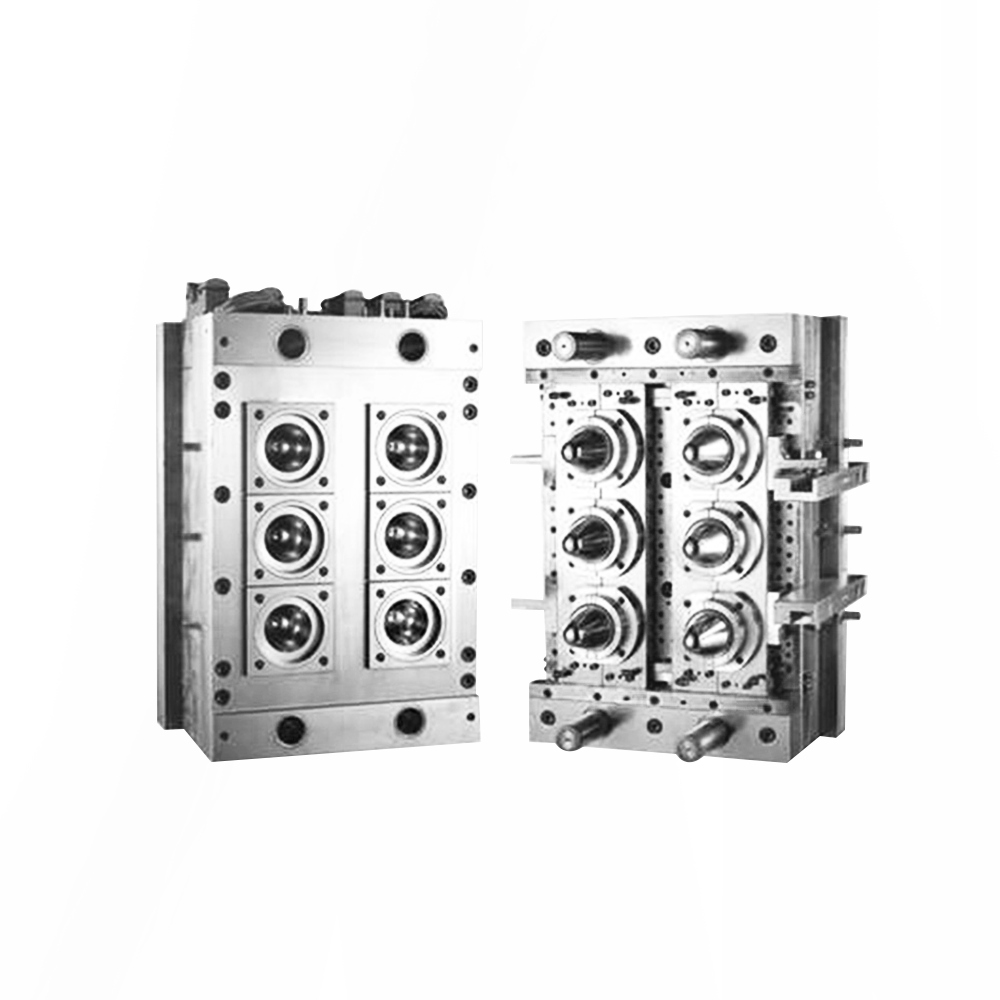

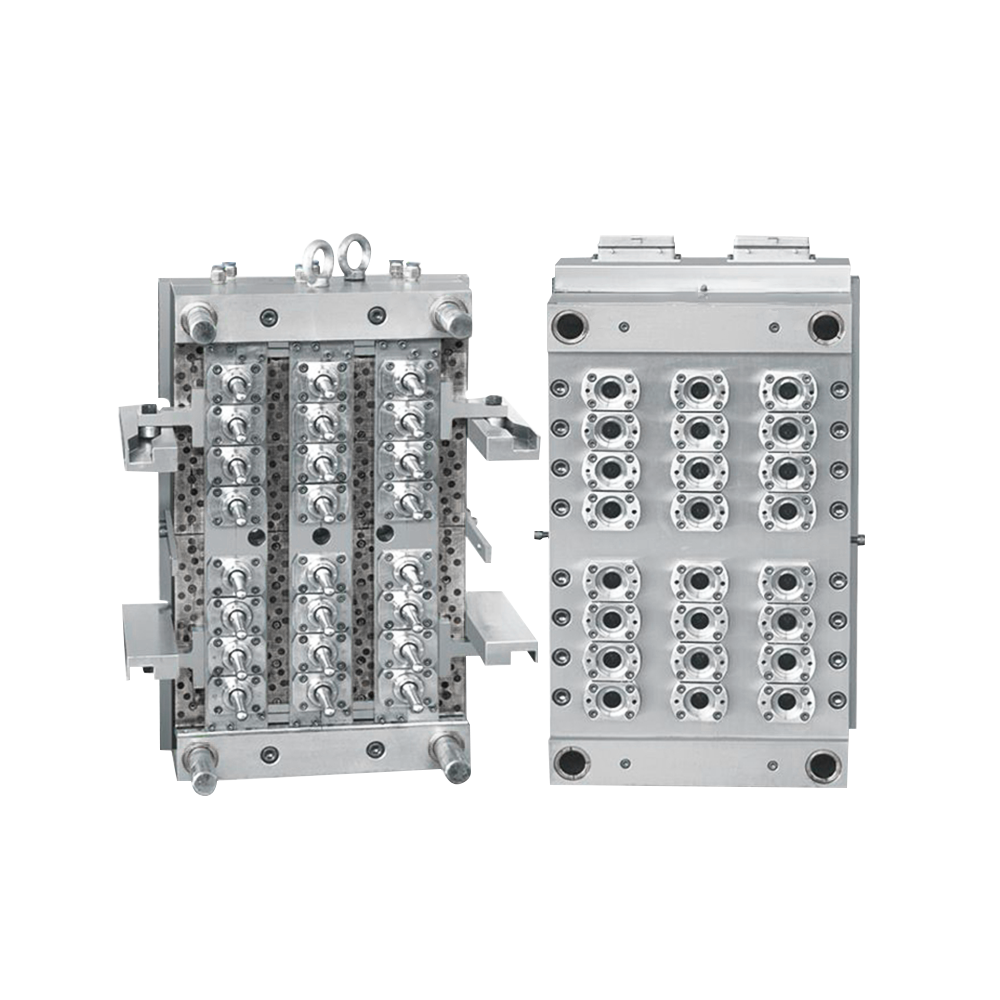

Preform injection molding is a manufacturing process used to produce parts with high accuracy and consistency. It involves injecting molten material into a mold cavity, which is then cooled and solidified to form the desired shape. Here are some benefits of using preform injection mold custom:

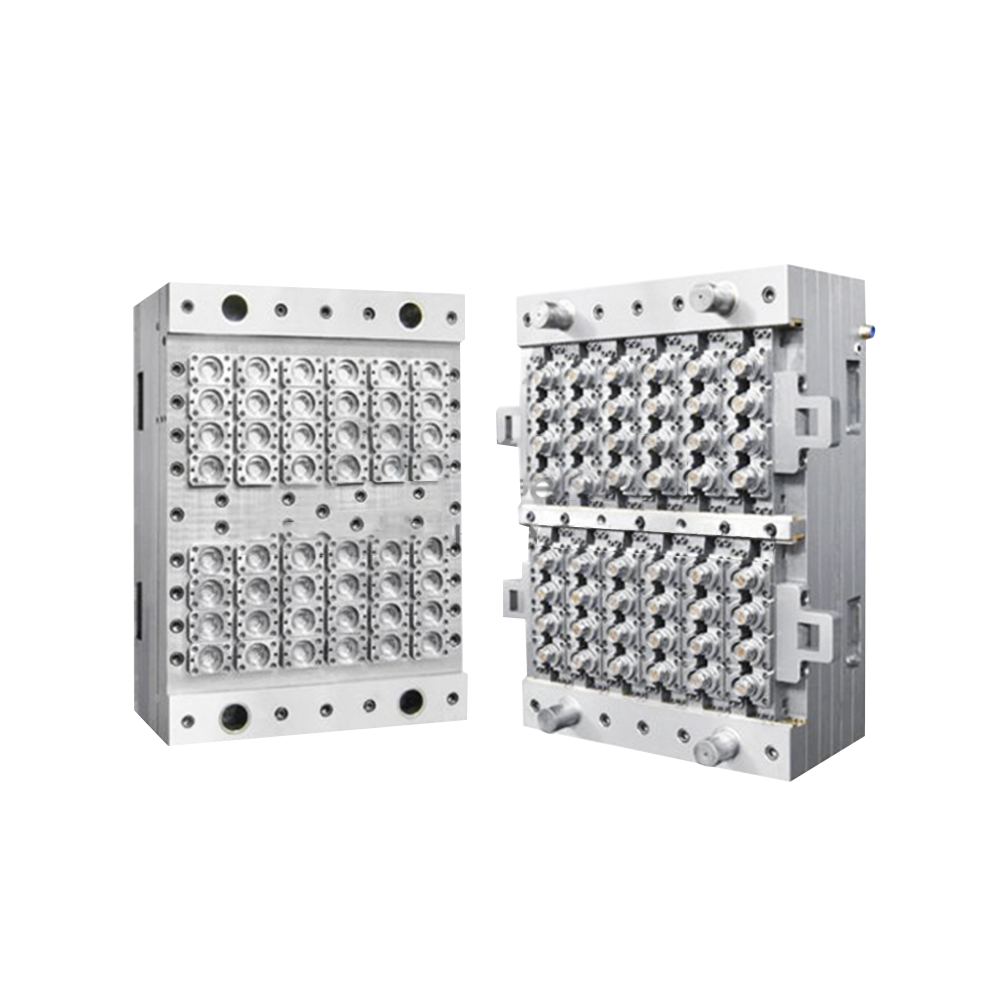

High accuracy: Preform injection molding allows for high accuracy and precision in producing custom parts. The mold can be designed to exact specifications, ensuring that each part is identical.

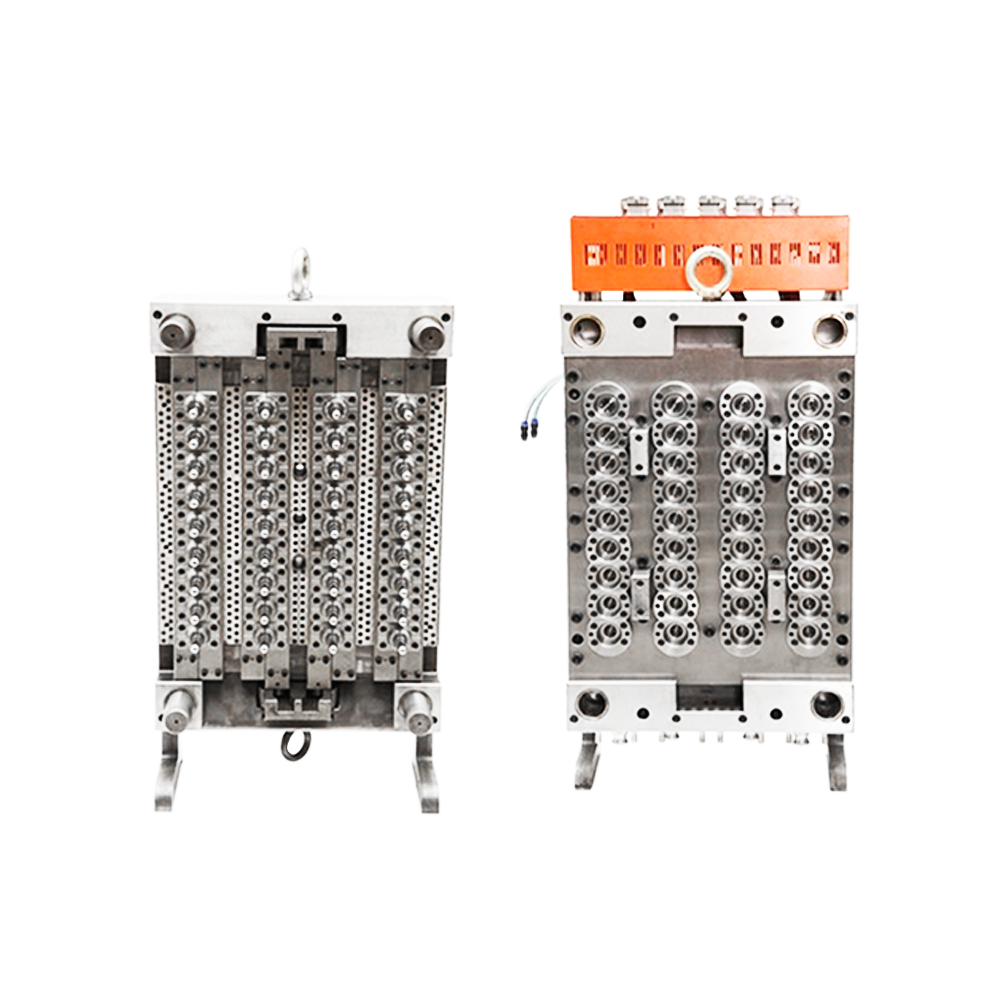

Efficient production: Preform injection molding is an efficient process that can produce a high volume of parts quickly. This can lead to cost savings, as it reduces the need for manual labor and can produce parts at a faster rate.

Consistency: Preform injection molding produces parts that are consistent in size, shape, and quality. This consistency is important for products that require a high level of precision or for parts that need to fit together perfectly.

Versatility: Preform injection molding can be used with a wide range of materials, including plastic, metal, and rubber. This versatility makes it an ideal choice for a variety of industries.

Customization: Preform injection molding allows for customization of parts. The mold can be designed to produce parts with unique shapes and sizes, and even complex geometries.

Reduced waste: Preform injection molding produces very little waste, as any excess material can be reused. This can lead to cost savings and also makes it a more sustainable manufacturing process.

In summary, preform injection mold custom offers a range of benefits, including high accuracy, efficient production, consistency, versatility, customization, and reduced waste. These benefits make it a popular choice for manufacturing parts across a range of industries.

English

English عربى

عربى Español

Español