The principle of prefabricated die

Dec 01,2022

Dec 01,2022

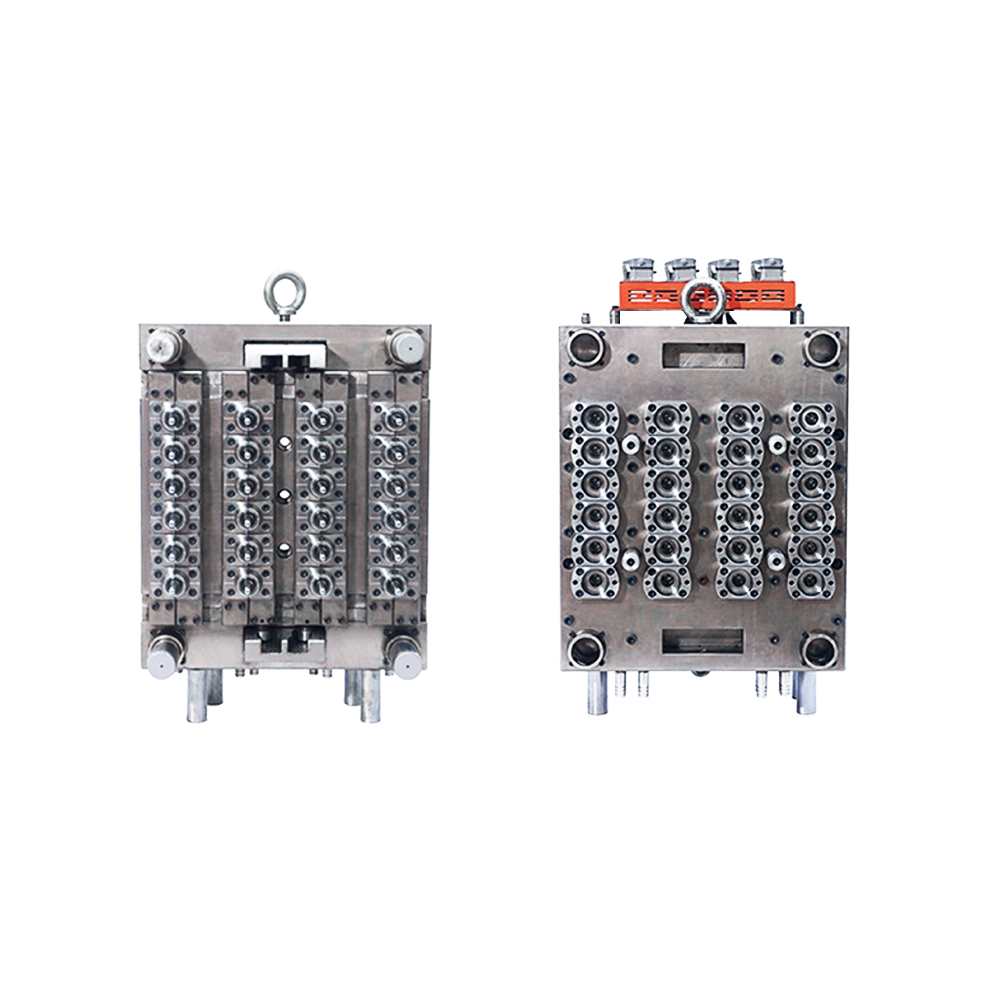

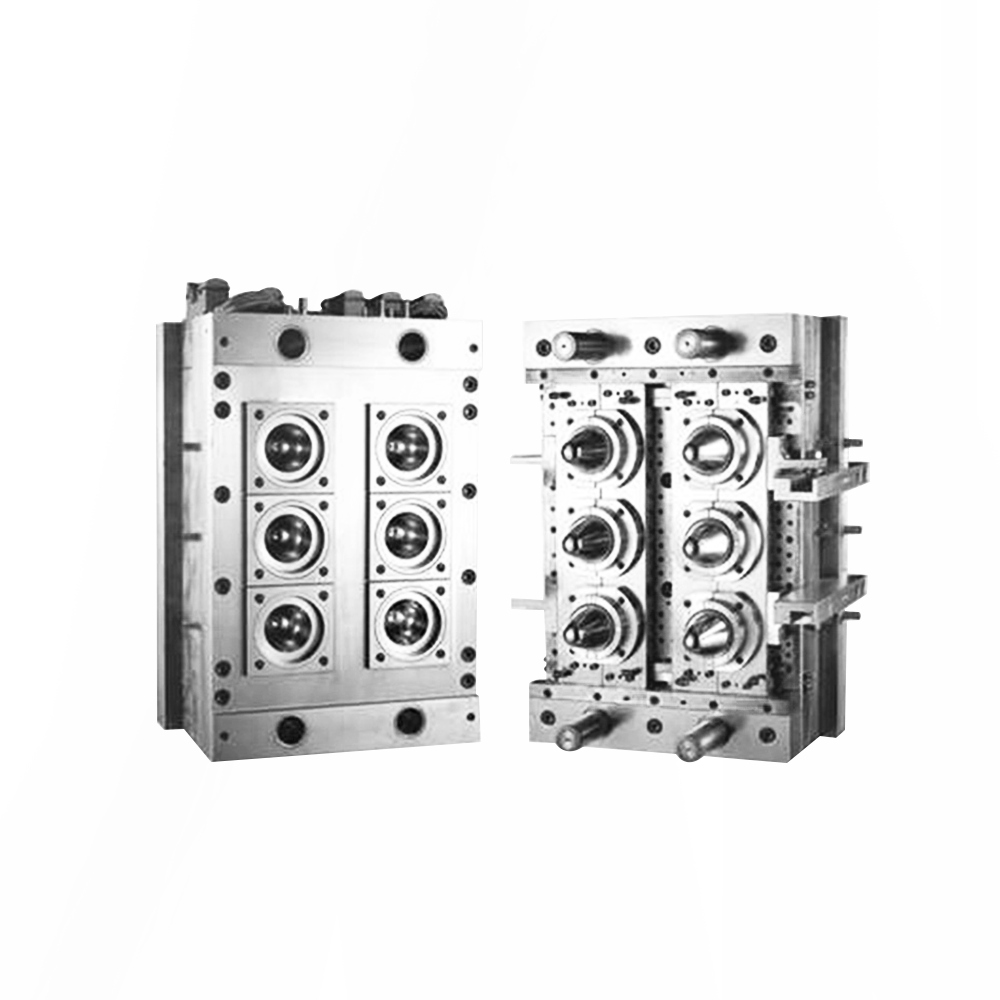

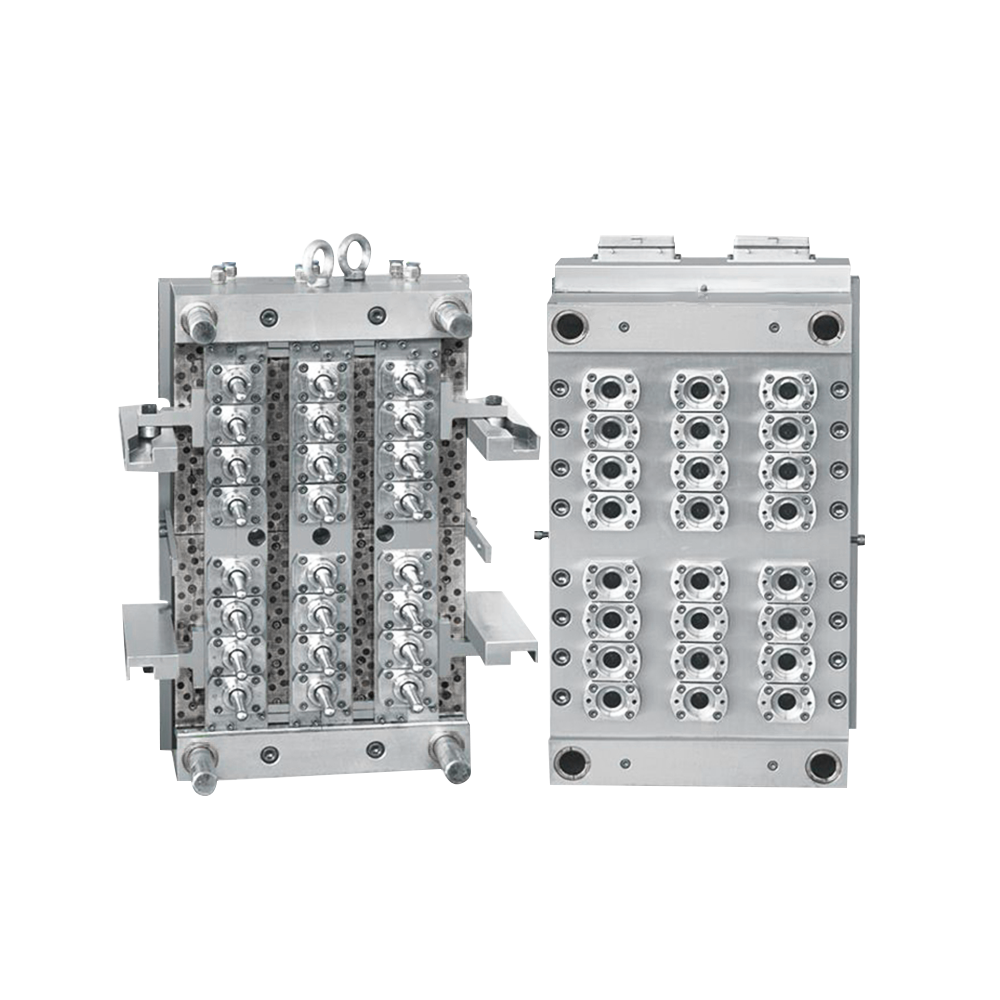

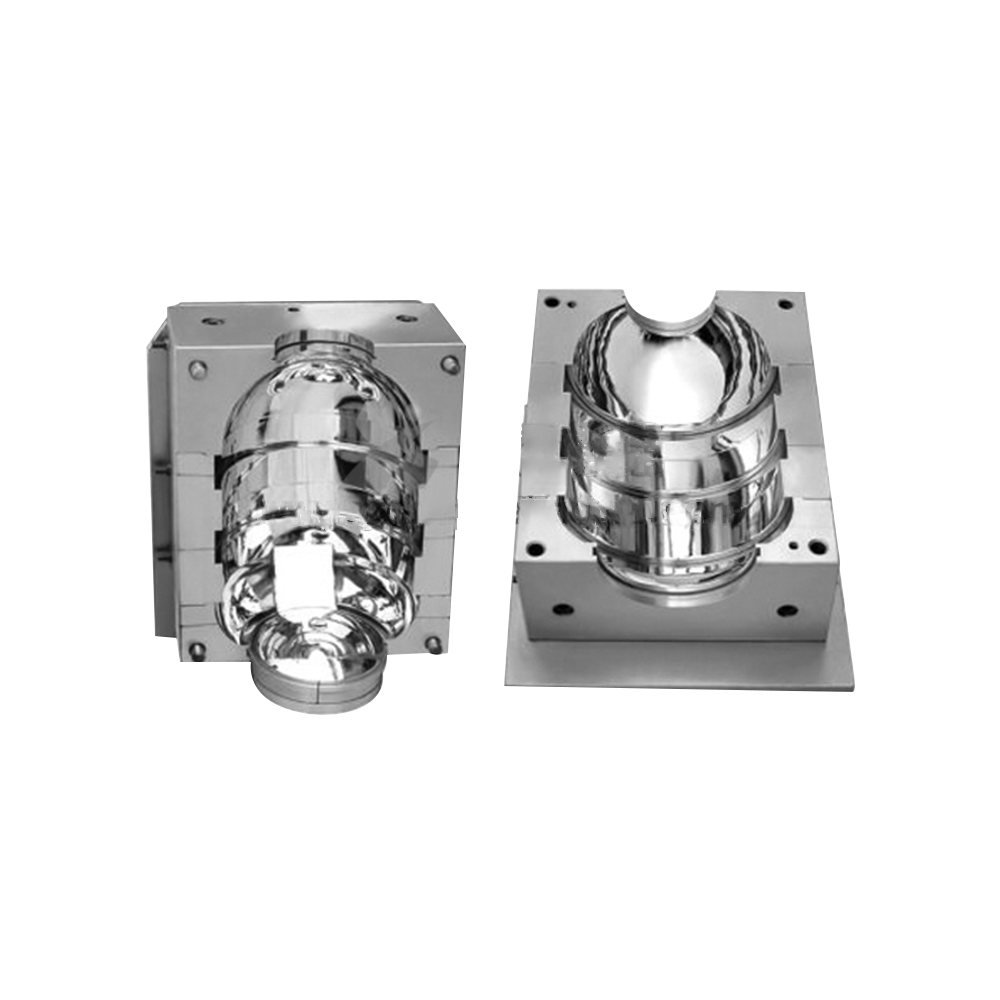

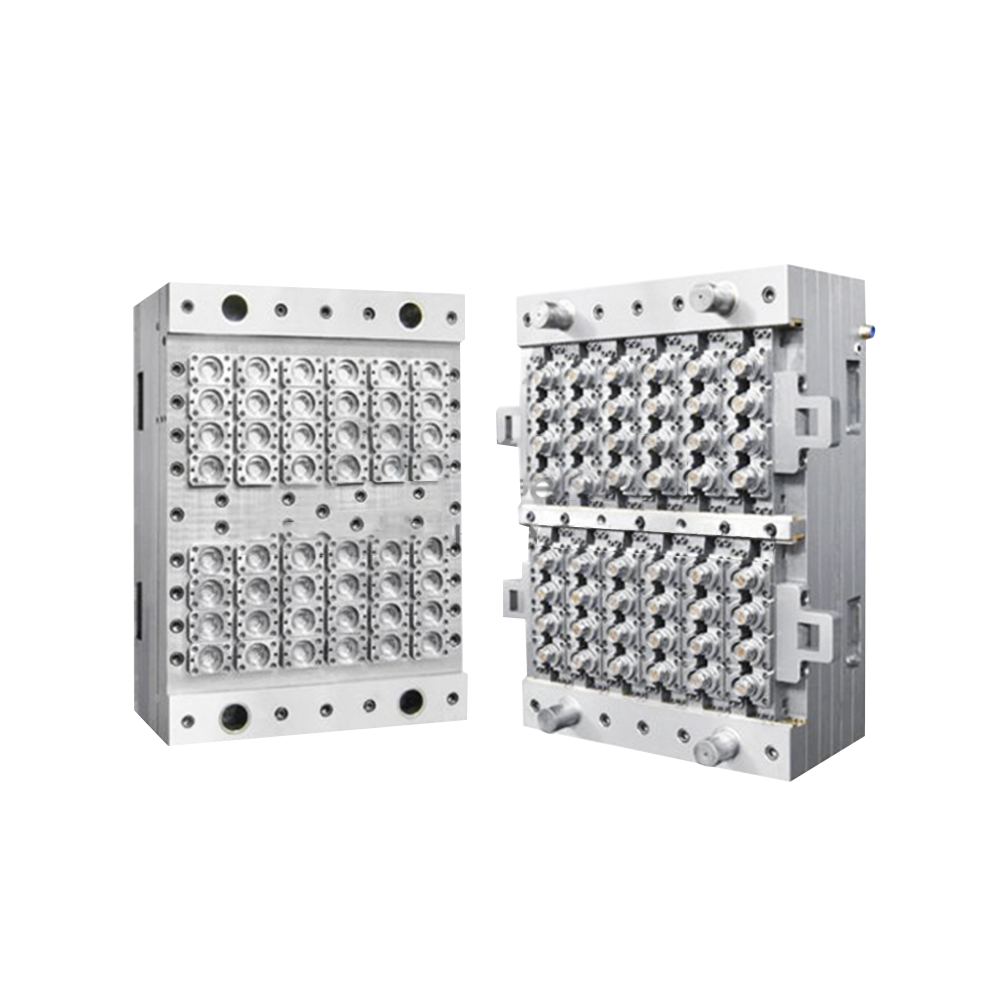

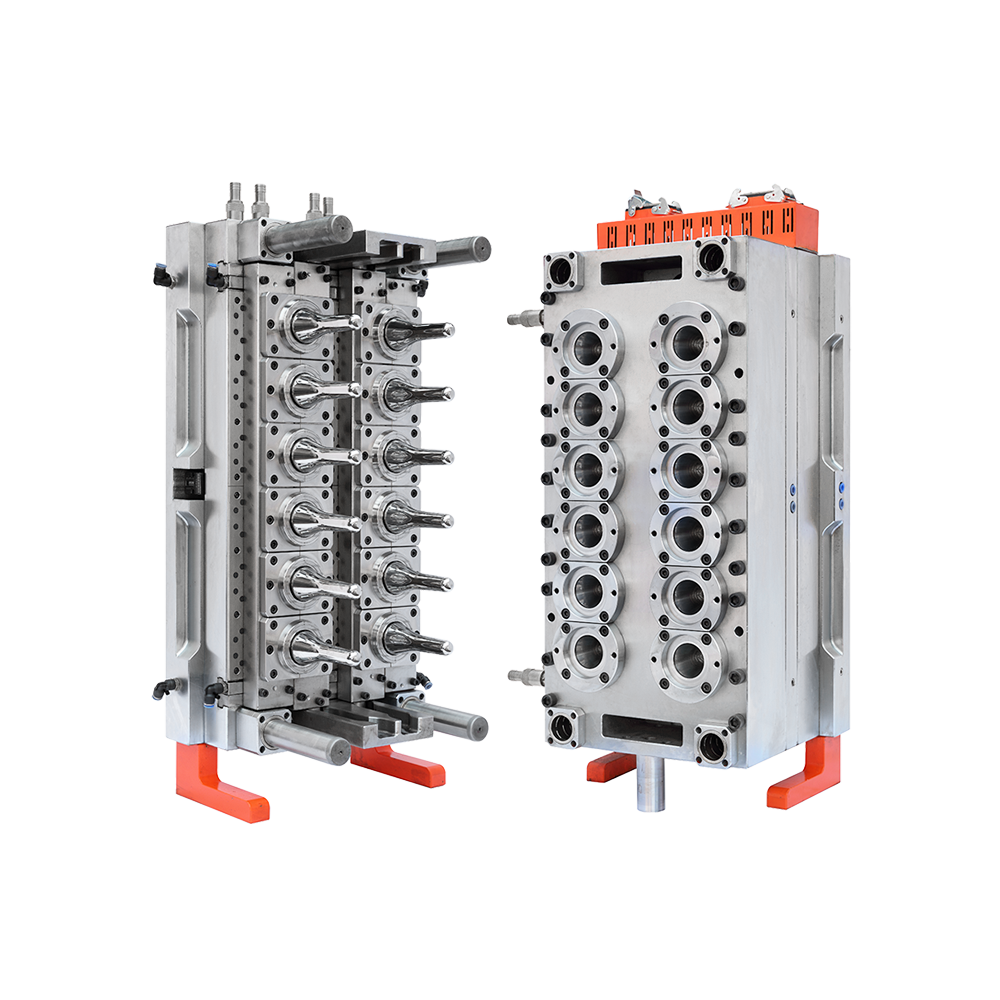

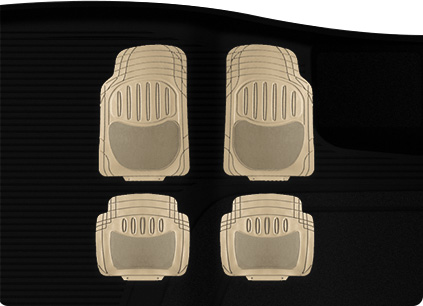

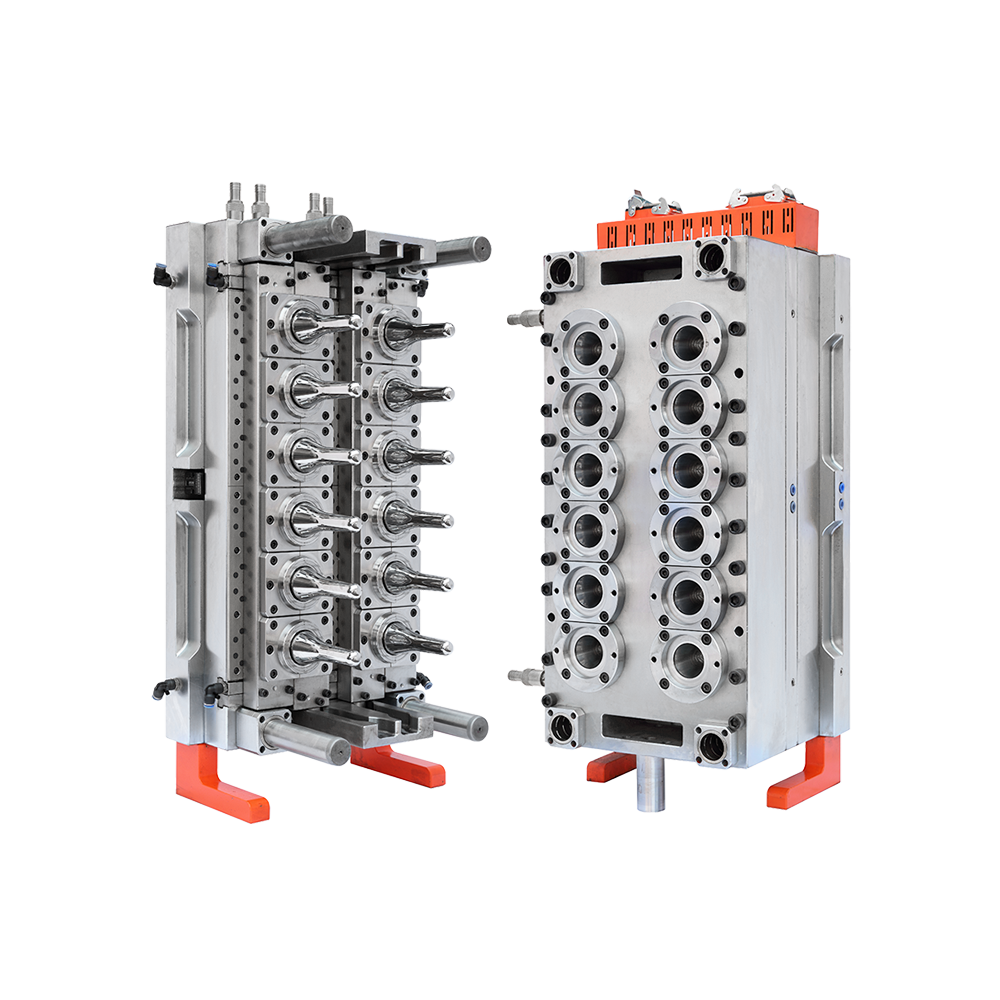

Taizhou Huangyan Xuejun Mold Co., Ltd. is a professional Custom PET Preform Mould Manufacturers of PET tube blank mould, bottle cap mould and bottle blowing mould.

No.777, Dujia Village, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, China

-86-15215807999

-86-15215807999

+86-576-84115538

+86-576-84115538

+86-576-84115538

+86-576-84115538

xuejun@china-petmould.com

xuejun@china-petmould.com

Copyright © Taizhou Huangyan Xuejun Mold Co., Ltd. . All Rights Reserved.