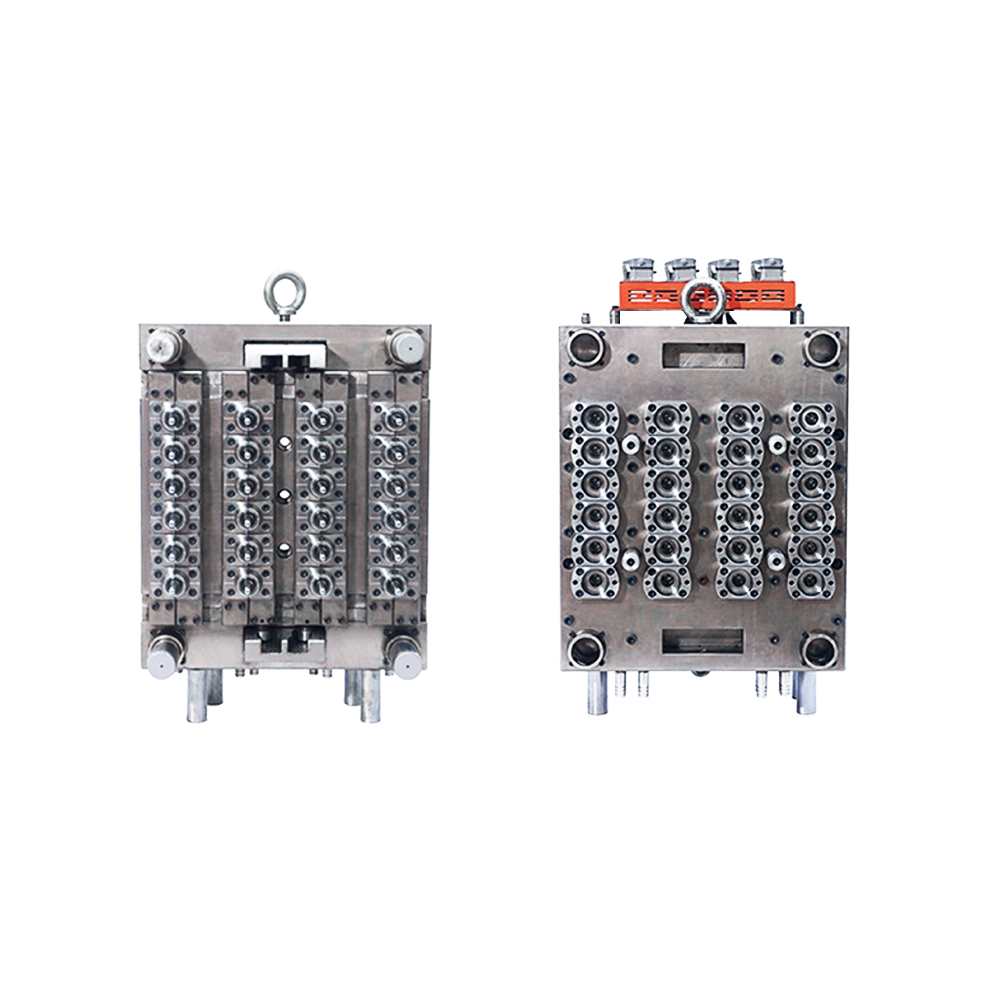

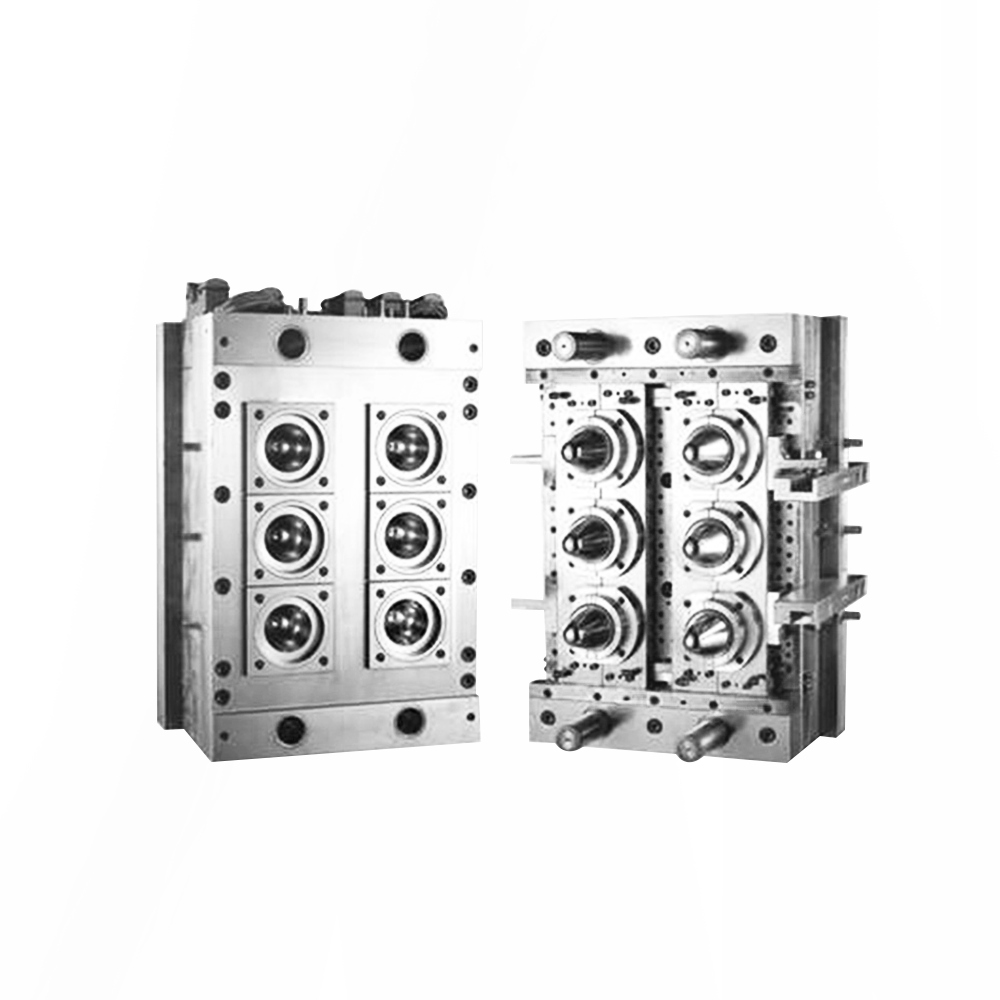

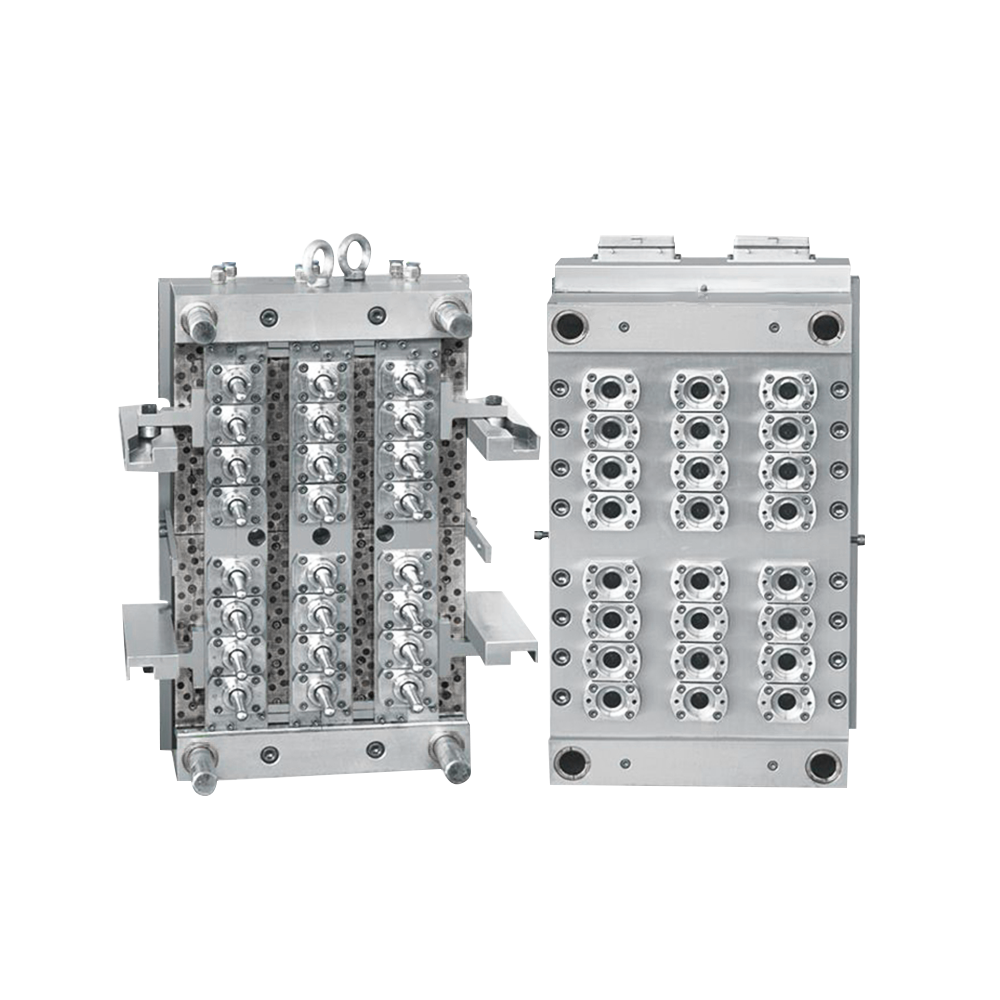

Understanding the Advantages of Preform Moulds in Beverage Packaging

Apr 05,2024

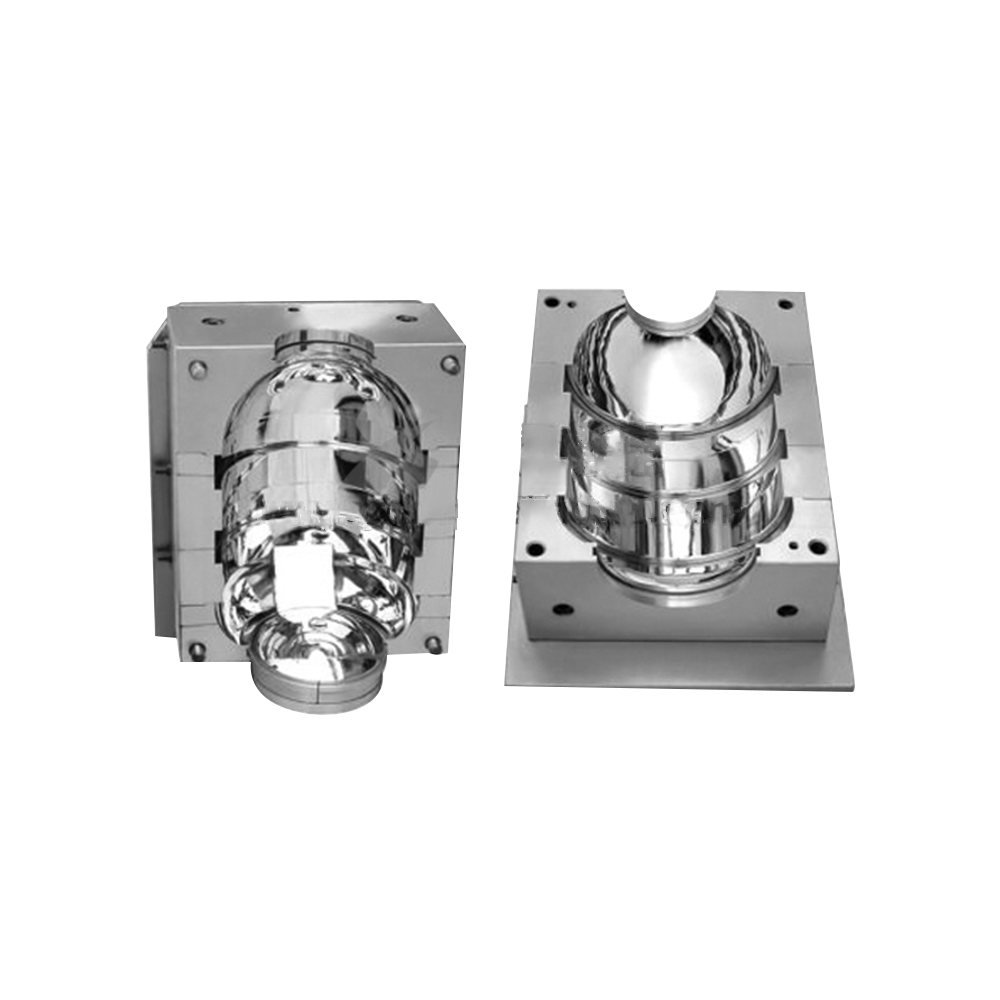

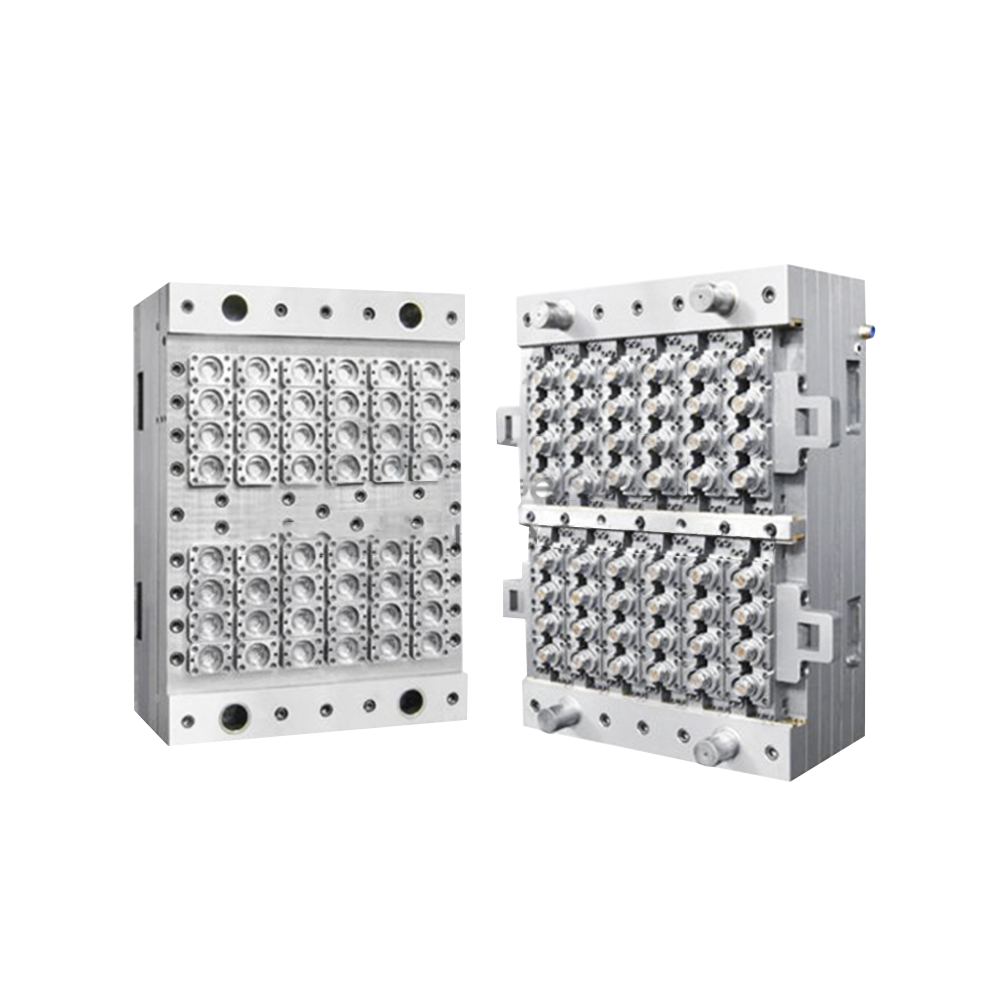

Sale High Quality Preform Mould in China

Beverage packaging plays a crucial role in the overall success of a product in the market. One of the commonly used packaging materials is plastic, specifically in the form of preform moulds. Sale Preform Moulds are an essential component in the production of plastic bottles, which are used for packaging a wide range of beverages. This article aims to explore the various advantages of using preform moulds in beverage packaging, focusing on their impact on the environment, cost-effectiveness, and overall product quality.

One of the primary concerns for beverage manufacturers today is the environmental impact of their packaging materials. Sale Preform Moulds offer a more sustainable solution compared to traditional glass or metal containers. The production process of preform moulds generates less waste and requires less energy, making them a more environmentally friendly option. Additionally, preform moulds are lightweight, which reduces transportation costs and fuel consumption, further minimizing their carbon footprint.

The use of preform moulds in beverage packaging is a cost-effective solution for manufacturers. The production of preform moulds is relatively inexpensive, and the materials used, such as polyethene terephthalate (PET), are widely available and affordable. This cost savings is passed on to the consumer, making beverages packaged in preform mould-based containers more accessible to a broader market.

Moreover, Sale Preform Moulds can be easily recycled, reducing the overall cost of waste management for manufacturers. The recycling process of preform moulds is well-established and efficient, allowing manufacturers to repurpose the materials for the production of new preform moulds, further reducing costs and waste.

Preform moulds offer a high level of versatility in terms of shape, size, and design. Manufacturers can customize preform moulds to create unique and eye-catching packaging for their beverages, setting their products apart from competitors. This versatility also allows for the production of preform moulds in various sizes, accommodating different volumes of beverages and catering to diverse consumer preferences.

Preform moulds are designed to withstand the pressures and stresses of the beverage packaging process. They are made from durable materials, such as PET, which are resistant to impact and can maintain their shape and integrity even when subjected to high temperatures and pressures. This ensures that the final product is strong and durable, protecting the beverage from damage and spoilage during transportation and storage.

The use of preform moulds in beverage packaging allows for improved sealing and safety features. Preform moulds can be designed with tamper-evident seals and resealable caps, providing consumers with a safe and secure product. This added level of safety and security can help to build consumer trust and confidence in the product, thereby contributing to increased sales and brand loyalty.

The production process of preform moulds is relatively quick and efficient, allowing for faster turnaround times for manufacturers. This increased speed can help to meet the demands of a competitive market, ensuring that products are available to consumers on time. Additionally, the faster production process can help to reduce manufacturing costs, further contributing to the cost-effectiveness of using preform moulds in beverage packaging.

Preform moulds are suitable for packaging a wide range of beverages, including water, soft drinks, juices, and alcoholic beverages. This adaptability allows manufacturers to use a single type of packaging for multiple product lines, streamlining their production process and reducing the need for multiple packaging materials and equipment.

Due to their lightweight nature and durable design, preform moulds are easy to store and transport. This ease of storage and transportation can help to reduce logistical costs for manufacturers, contributing to the overall cost-effectiveness of using preform moulds in beverage packaging.

Preform moulds are designed with the end consumer in mind. They are easy to open, hold, and pour, making them a user-friendly option for consumers. This focus on consumer convenience can help to increase customer satisfaction and encourage repeat purchases.

In conclusion, the use of preform moulds in beverage packaging offers numerous advantages for both manufacturers and consumers. These advantages include a reduced environmental impact, cost-effectiveness, versatility, strength and durability, improved sealing and safety, enhanced aesthetics, faster production processes, adaptability to different beverage types, easy storage and transportation, and consumer-friendly design. By understanding and utilizing these advantages, beverage manufacturers can create high-quality, sustainable, and visually appealing.

English

English عربى

عربى Español

Español