What is Blow Mould and The Importance of Blow Mould

Apr 23,2023

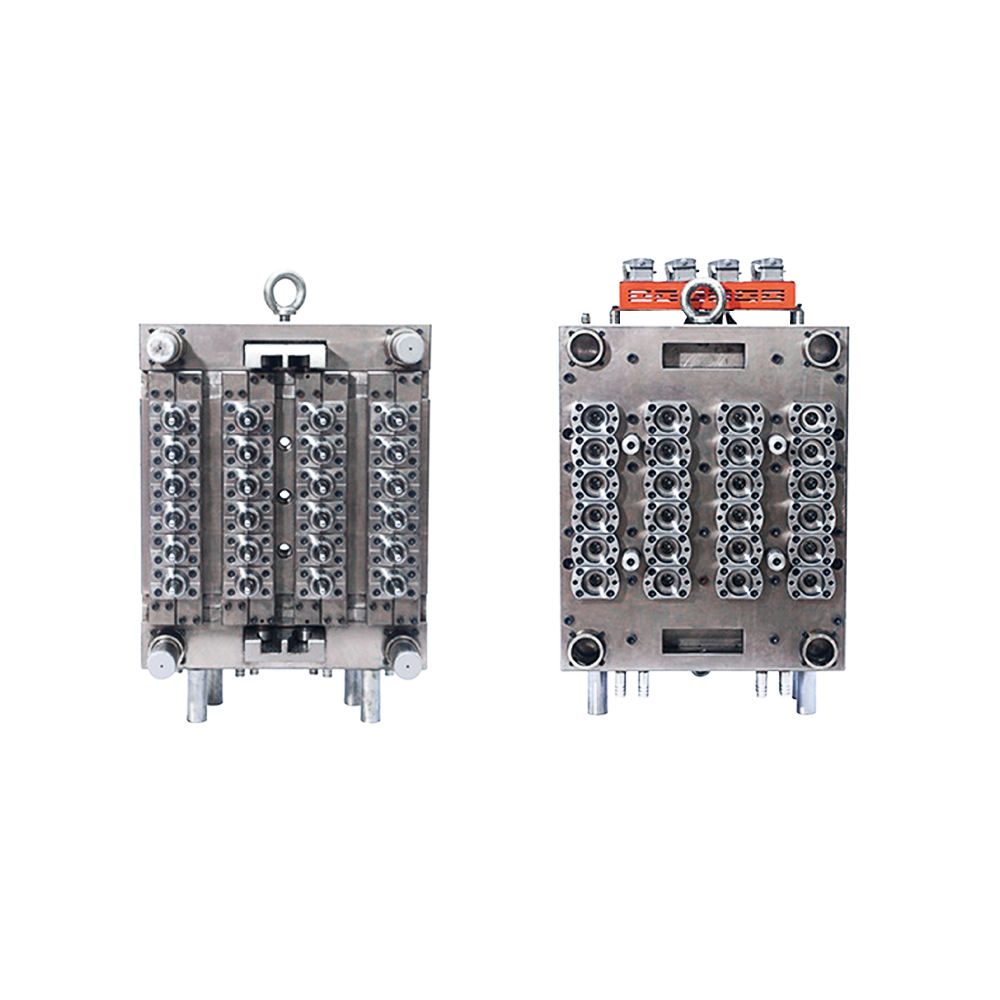

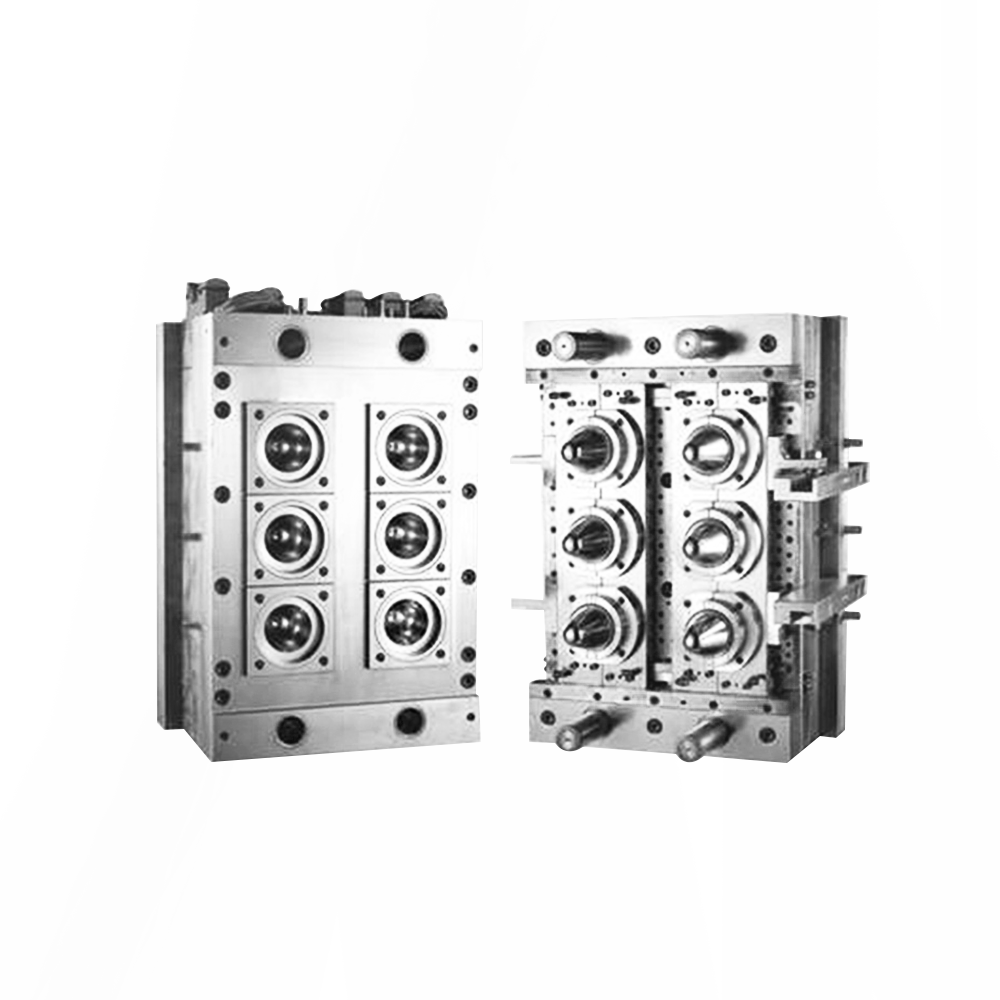

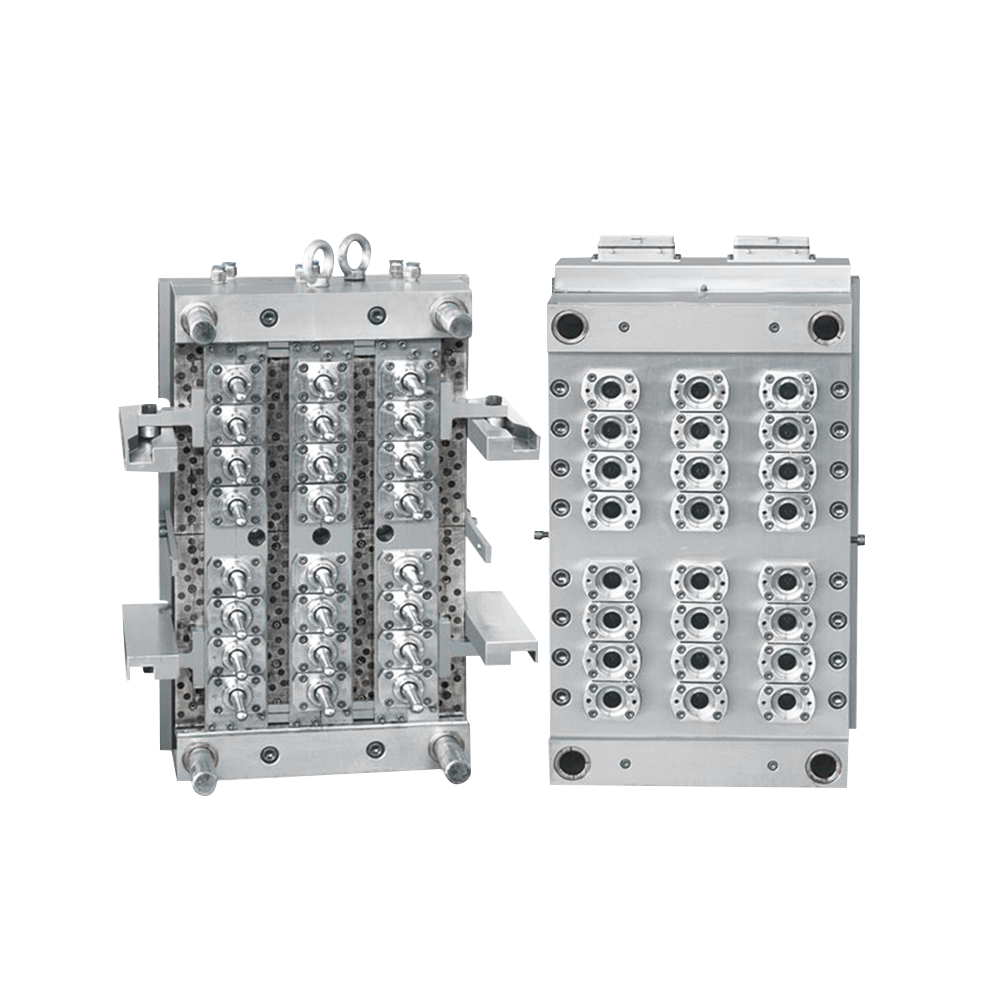

Blow molding is a manufacturing process used to create hollow plastic parts, such as bottles, containers, and jars. The process involves melting plastic resin and then shaping it into a hollow form using air pressure. Here are the basic steps of the blow molding process:Melting: Plastic resin pellets are melted down and extruded into a long, tubular shape called a parison.Preparing the mold: A two-piece mold is clamped together around the parison.Blow molding: Compressed air is forced into the parison, causing it to expand and take the shape of the mold. The plastic cools and hardens, creating a hollow plastic part.Ejection: The mold is opened, and the finished part is ejected.There are several different types of blow molding, including extrusion blow molding, injection blow molding, and stretch blow molding. Each type has its own advantages and is used for specific applications.

Overall, blow molding is a cost-effective and efficient way to produce a wide variety of plastic parts. It is commonly used in the manufacturin.Bedsides,Blow molding is an important manufacturing process in the production of a wide variety of plastic products. Here are some of the key benefits and advantages of blow molding:

Cost-effective production: Blow molding is a cost-effective way to produce high volumes of plastic parts with consistent quality. The process can be automated, which reduces labor costs and increases efficiency.Lightweight and durable products: Blow-molded products are lightweight and durable, making them ideal for a wide range of applications. The plastic used in blow molding is also resistant to chemicals, UV rays, and impact, which further enhances the durability of the finished product.Versatility: Blow molding can produce a wide variety of products in different shapes and sizes, including bottles, containers, and packaging materials. The process can also use different types of plastic resins, such as polyethylene, polypropylene, and PVC.Sustainability: Blow molding can use recycled materials, reducing the amount of waste that goes into landfills. The finished products can also be recycled, further reducing environmental impact.Customization: Blow molding can produce products with unique shapes and features, such as handles, spouts, and caps. This allows for customization and branding opportunities for manufacturers.

Overall, blow molding is an important manufacturing process that offers a cost-effective way to produce a wide variety of lightweight and durable plastic products. Its versatility, sustainability, and customization options make it a popular choice for manufacturers in various industries.

English

English عربى

عربى Español

Español