Are You Looking for High-Volume Bottle Cap Moulds for Efficient Production?

Apr 26,2024

Custom OEM Bottle Cap Mould Wholesaler

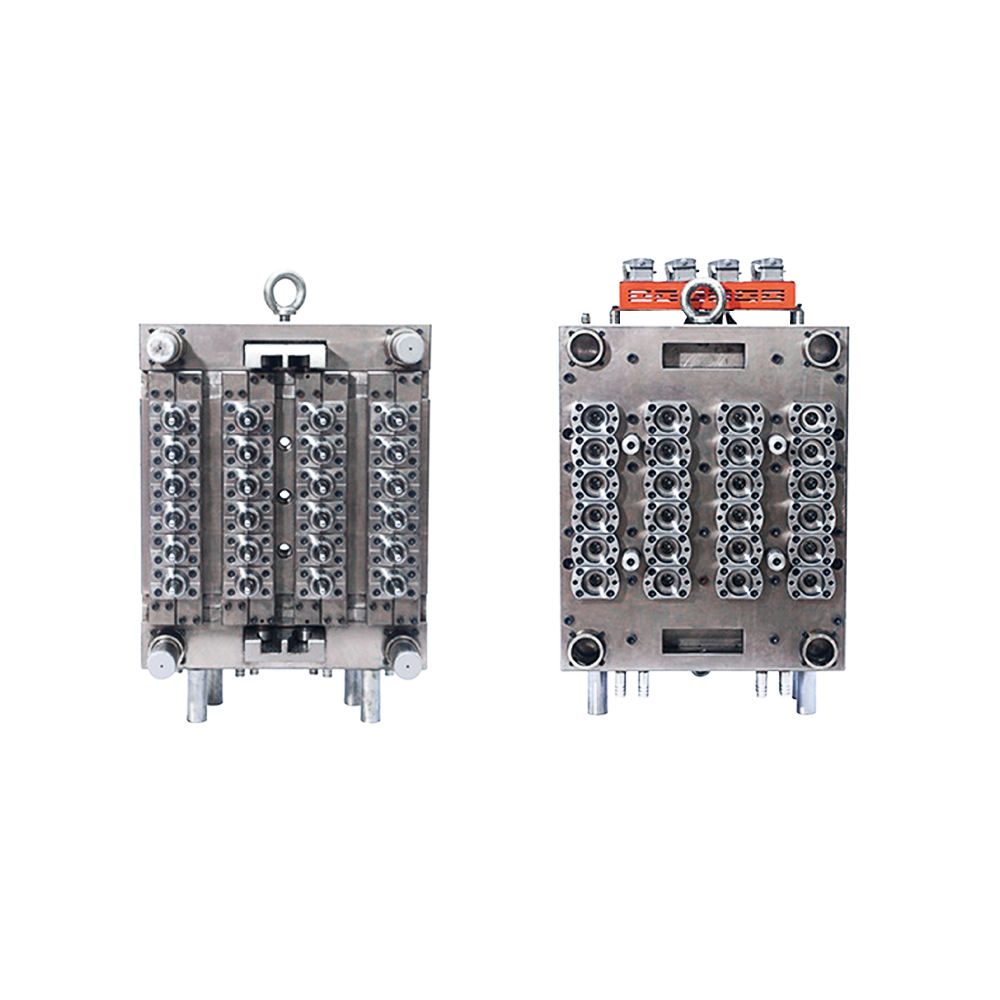

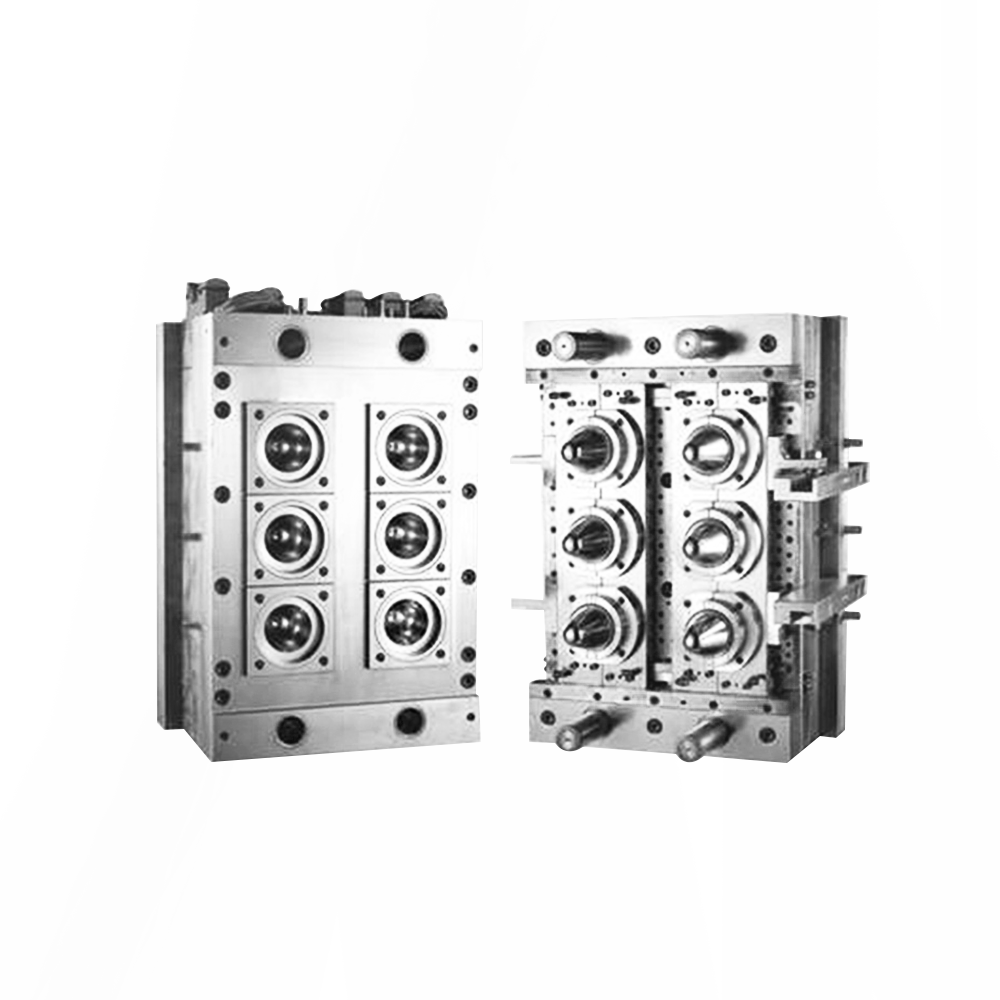

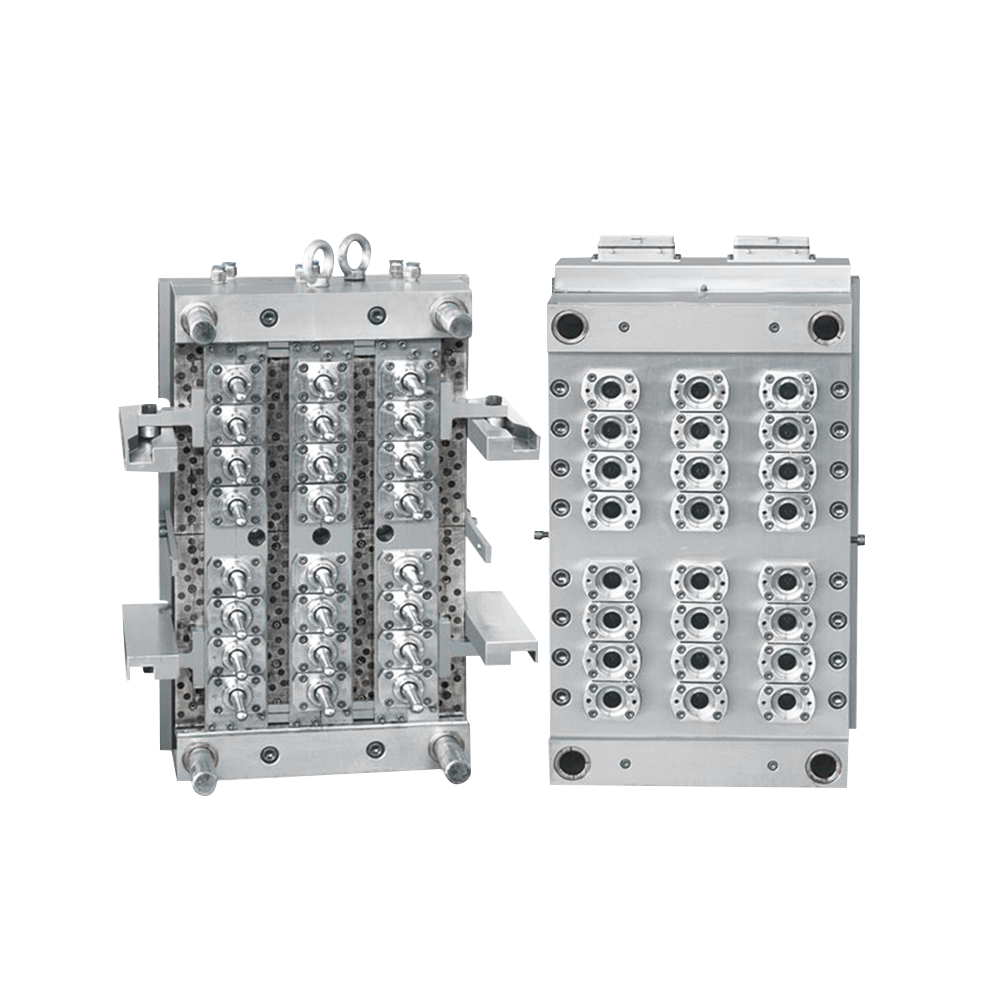

As a manufacturer of packaging moulds, it is very important to keep up with the new trends and needs of the market. One of the key aspects to consider is the efficiency of your production process, especially when it comes to producing bottle caps. Caps are an important part of many products, and having the right Custom Bottle Cap Mould to meet the requirements of mass production can play an important role in terms of yield and quality.

When it comes to selecting the right Custom Bottle Cap Moulds, there are several factors to consider. Above all, it is important to ensure that the moulds are designed to produce bottle caps that meet the specific requirements of your products. This includes factors such as the size and shape of the bottle cap, as well as the type of material used.

In addition to these considerations, it is also important to choose Custom Bottle Cap Moulds that are designed for high-volume production. This means selecting moulds that are capable of producing a large number of bottle caps in a short amount of time, without sacrificing quality.

One of the pressing issues in the packaging industry today is the need for environmentally sustainable solutions. Consumers are becoming increasingly aware of the impact of their purchasing decisions on the environment, and as a result, they are looking for products that are produced sustainably and responsibly. This is where high-volume bottle cap moulds come in. By using these moulds, manufacturers can produce large quantities of bottle caps in a cost-effective and environmentally friendly way.

Another important factor to consider when selecting bottle cap moulds is brand recognition. The design and shape of a bottle cap can play a significant role in the overall branding of a product. By investing in custom bottle cap moulds, manufacturers can create unique and distinctive bottle caps that will set their products apart from the competition. This can help to increase brand recognition and customer loyalty, thereby causing increased sales and revenue.

Durability is also a key factor to consider when it comes to bottle cap moulds. High-quality moulds will be able to withstand the wear and tear of high-volume production, ensuring that they continue to produce high-quality bottle caps time and time again. This can help to reduce downtime and maintenance costs, thereby causing increased efficiency and profitability.

Safety and security are also important considerations when it comes to bottle cap moulds. The right moulds will be designed to produce bottle caps that fit securely and tightly on the bottle, ensuring that the product inside remains protected and uncontaminated. This is especially important for products that are sensitive to light, air, or moisture, as a poorly fitting bottle cap can compromise the integrity of the product.

In addition to these factors, there are a number of other considerations that manufacturers should keep in mind when selecting bottle cap moulds. For example, it is important to choose moulds that are compatible with the materials and production methods being used. This can help to ensure that the bottle caps are produced efficiently and to a high standard of quality.

In conclusion, high-volume bottle cap moulds are an essential component of any successful packaging operation. By selecting the right moulds, manufacturers can increase their production output, enhance their brand recognition, and ensure the safety and security of their products. By taking the time to carefully consider these factors, manufacturers can make informed decisions and ultimately achieve their business goals.

English

English عربى

عربى Español

Español