Why Preform Mould Factory is the Future of Plastic Production?

May 03,2024

Sale Cheap Pet Jar Preform Mould Factory

The plastic industry has been a cornerstone of modern manufacturing, contributing to a wide array of products from packaging to automotive components. However, with the growing awareness of environmental sustainability and the need for efficient production methods, the industry is transforming. At the forefront of this evolution is the Preform Mould Factory, which is poised to redefine the future of plastic production. But why is this the case? Let's delve into the reasons why Sale Pet Preform Mould is the future of this industry.

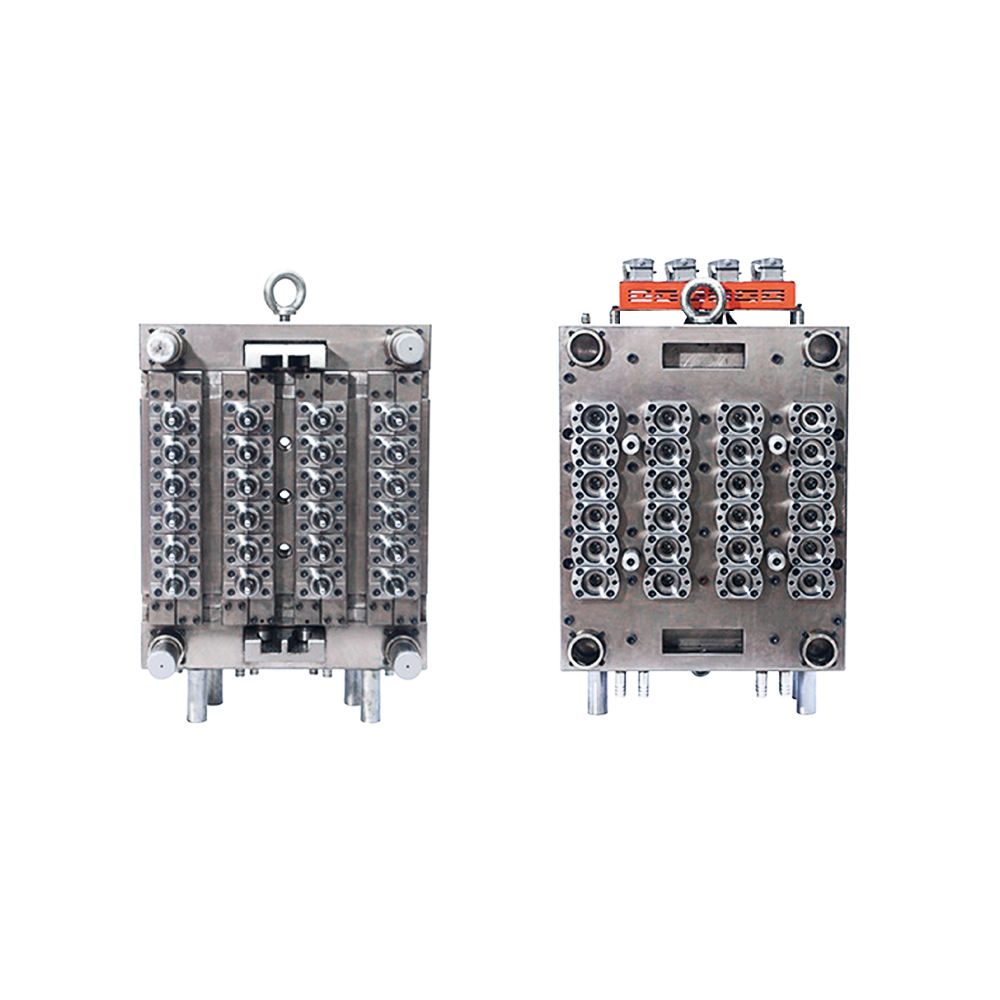

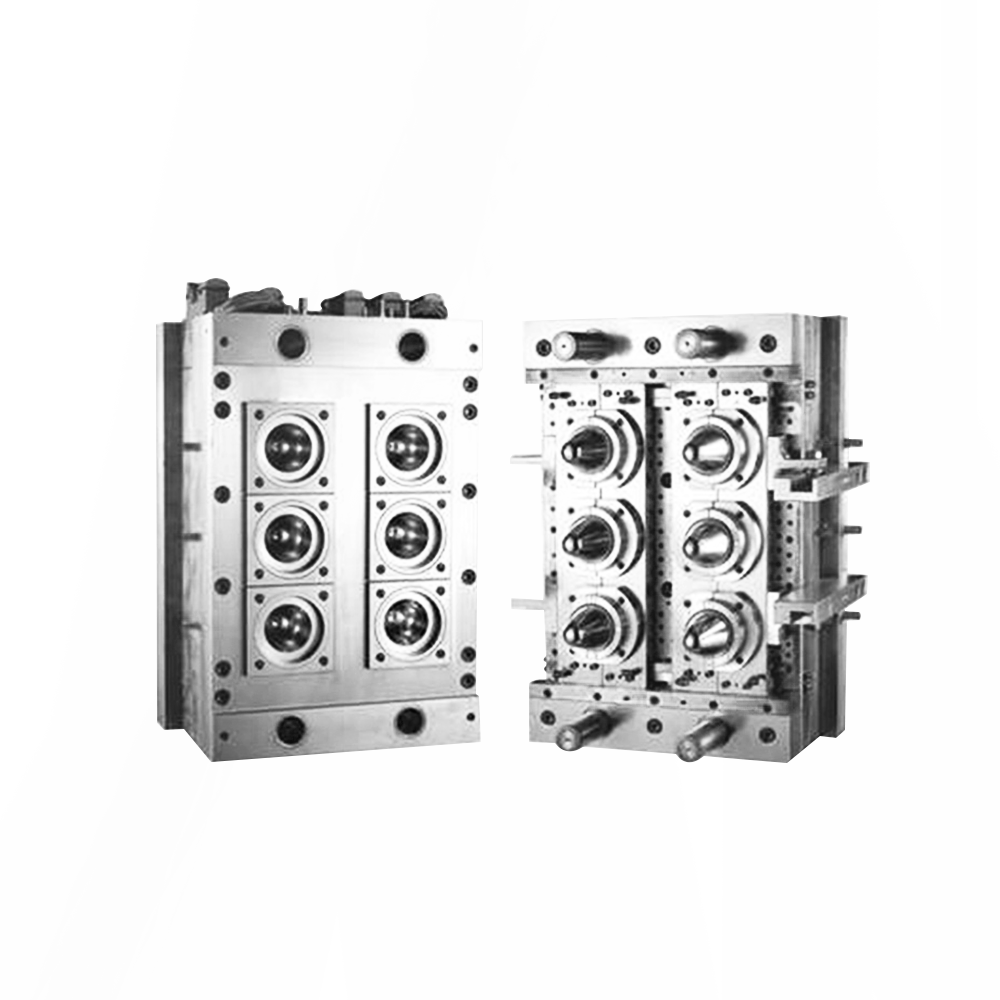

Cheap Jar Preform Mould is known for its precision engineering. The use of advanced technology in these factories allows for the creation of high-precision moulds that are essential for producing consistent, high-quality preforms. These forms are the foundation for various plastic products, from bottles to containers, and their quality directly impacts the final product.

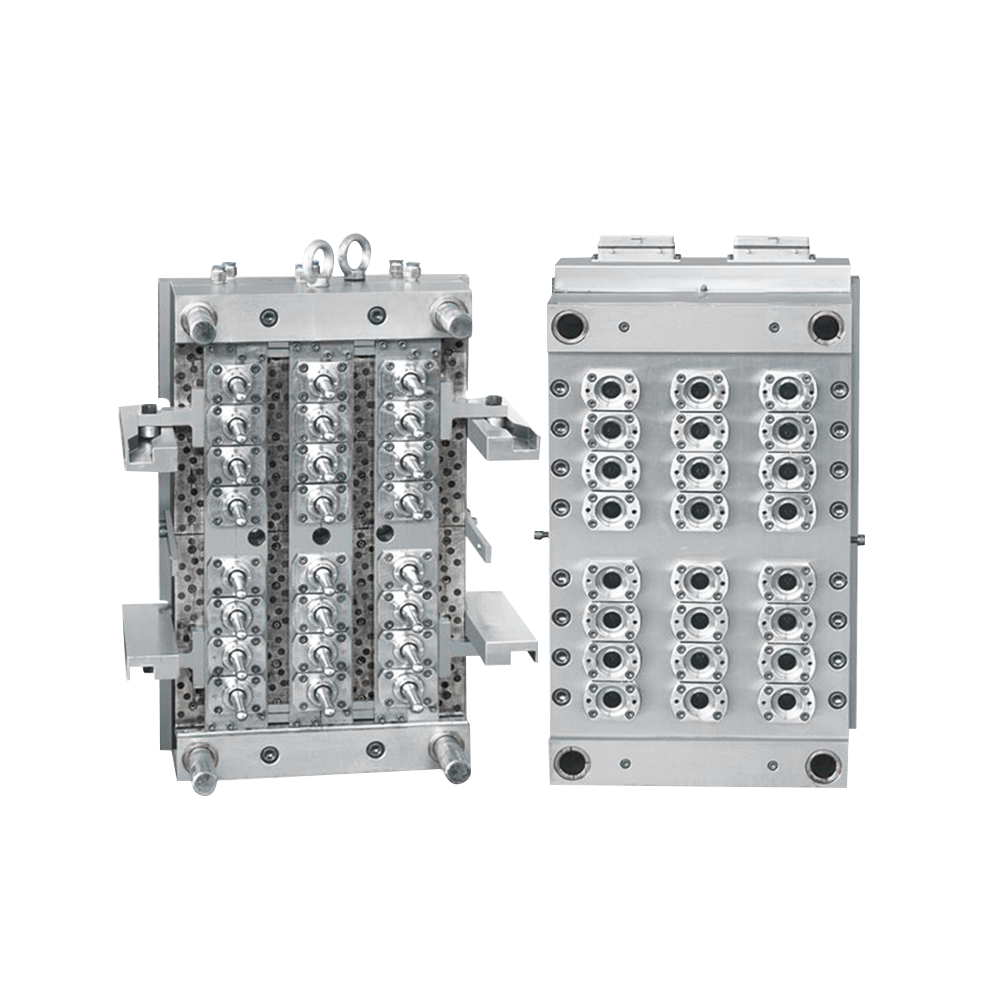

The automation and streamlined processes in Preform Mould Factory enable rapid production cycles. This efficiency is crucial for meeting the high demand for plastic products without compromising on quality. Faster production times also mean lower costs and quicker turnarounds for customers, which is a significant competitive advantage.

One of the significant advantages of Preform Mould Factory is its ability to offer customization. Manufacturers can design and produce moulds for a wide range of plastic products, catering to the specific needs of different industries. This flexibility allows for innovation and the development of new products that can meet unique market demands.

As the world moves towards more sustainable practices, Preform Mould Factory is adapting by implementing eco-friendly manufacturing processes. By reducing waste and energy consumption, these factories are contributing to the reduction of the plastic industry's environmental footprint. The use of recycled materials and the development of biodegradable preforms are also part of this shift towards sustainability.

The integration of cutting-edge technology in Preform Mould Factory is driving innovation in plastic production. From computer-aided design (CAD) and computer-aided manufacturing (CAM) to 3D printing and robotics, these technologies are enhancing the capabilities of Preform Mould Factory, allowing them to produce more complex and intricate designs.

The economies of scale achieved in Preform Mould Factory translate to cost savings for manufacturers. By producing large quantities of preforms at a lower cost per unit, these factories can offer competitive pricing to their customers. This cost-effectiveness is a significant draw for businesses looking to reduce their production costs without sacrificing quality.

Preform Mould Factory is not just about production; they are also a centre for innovation. By working closely with designers and engineers, these factories can bring new and creative ideas to life. This collaborative approach fosters a culture of innovation that can lead to the development of groundbreaking products.

With the rise of globalization, Preform Mould Factory is expanding its reach to serve a global market. This expansion allows them to tap into new markets and opportunities, further solidifying their role in the future of plastic production.

Investing in the workforce is a key strategy for Preform Mould Factory. By providing training and development opportunities, these factories are ensuring that they have a skilled workforce capable of operating and maintaining the advanced machinery and processes required for modern plastic production.

The future of plastic production is not just about what is to come; it is already here. Preform Mould Factory is pioneering the way with its innovative approaches to manufacturing, sustainability, and design. As the industry continues to evolve, these factories will play a critical role in shaping the future of plastic production.

In conclusion, Preform Mould Factory is set to revolutionize the plastic industry through its focus on precision, efficiency, customization, environmental responsibility, technological integration, cost-effectiveness, and a commitment to innovation and workforce development. As the world demands more from its manufacturing processes, Preform Mould Factory is rising to the challenge, proving that they are indeed the future of plastic production.

English

English عربى

عربى Español

Español