How Preform Mould Factory is Going Green?

May 10,2024

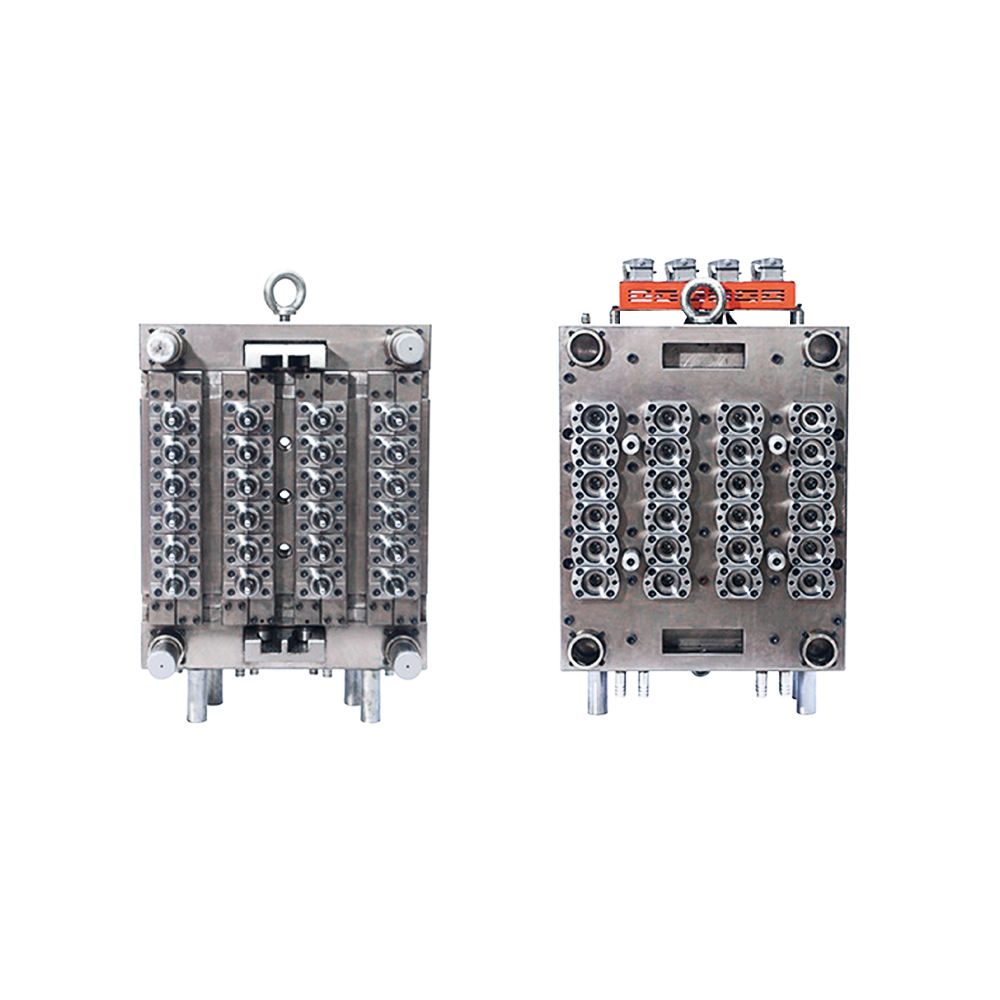

Custom OEM Preform injection blow molding Mould Factory

The manufacturing industry has long been a significant contributor to environmental pollution and resource depletion. However, with the growing awareness of the need for sustainable practices, Preform Mould Factory is taking the lead in implementing green initiatives. This article will explore the various ways in which these factories are adopting eco-friendly measures to reduce their environmental impact and contribute to a greener future.

Preform Mould Factory is investing in energy-efficient machinery and equipment to reduce its energy consumption. By using less energy, these factories not only lower their operational costs but also decrease their carbon footprint.

One of the primary concerns for any manufacturing facility is waste management. Custom preform injection molding is implementing waste reduction strategies, such as recycling and reusing materials, to reduce the amount of waste generated during the production process.

The use of sustainable materials is another key aspect of going green. Preform Mould Factory is sourcing materials that are either biodegradable or have a lower environmental impact. This shift in material sourcing is crucial for reducing the industry's overall ecological footprint.

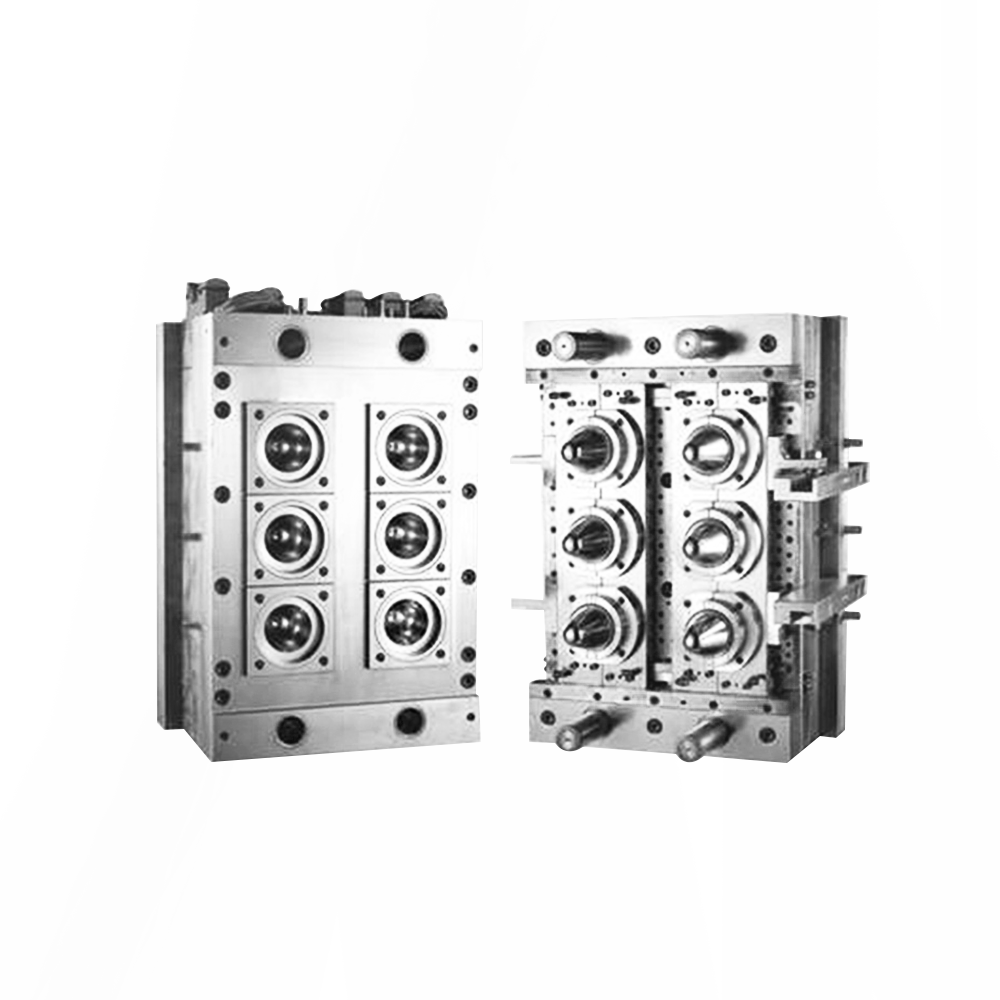

Water is a vital resource, and its conservation is essential for sustainable manufacturing. Preform Mould Factory is adopting water-saving technologies and practices to reduce water usage in its operations.

Obtaining green certifications is another way Preform Mould Factory is demonstrating its commitment to sustainability. Certifications like ISO 14001 and LEED can help factories showcase their environmental management systems and sustainable practices to customers and stakeholders.

Educating employees about the importance of sustainability and green practices is crucial. Preform Mould Factory is providing training to its workforce to ensure that everyone is aware of the steps they can take to contribute to a greener environment.

To counteract the carbon emissions they produce, Preform Mould Factory is investing in carbon offset projects. These projects, such as reforestation initiatives, help to balance out the carbon footprint of the factory's operations.

The transportation of goods also contributes to a company's carbon footprint. Preform Mould Factory is exploring greener transportation options, such as electric vehicles or biofuels, to reduce their emissions.

Switching to renewable energy sources is a significant step towards sustainability. Preform Mould Factory is installing solar panels or wind turbines to generate clean energy for their operations.

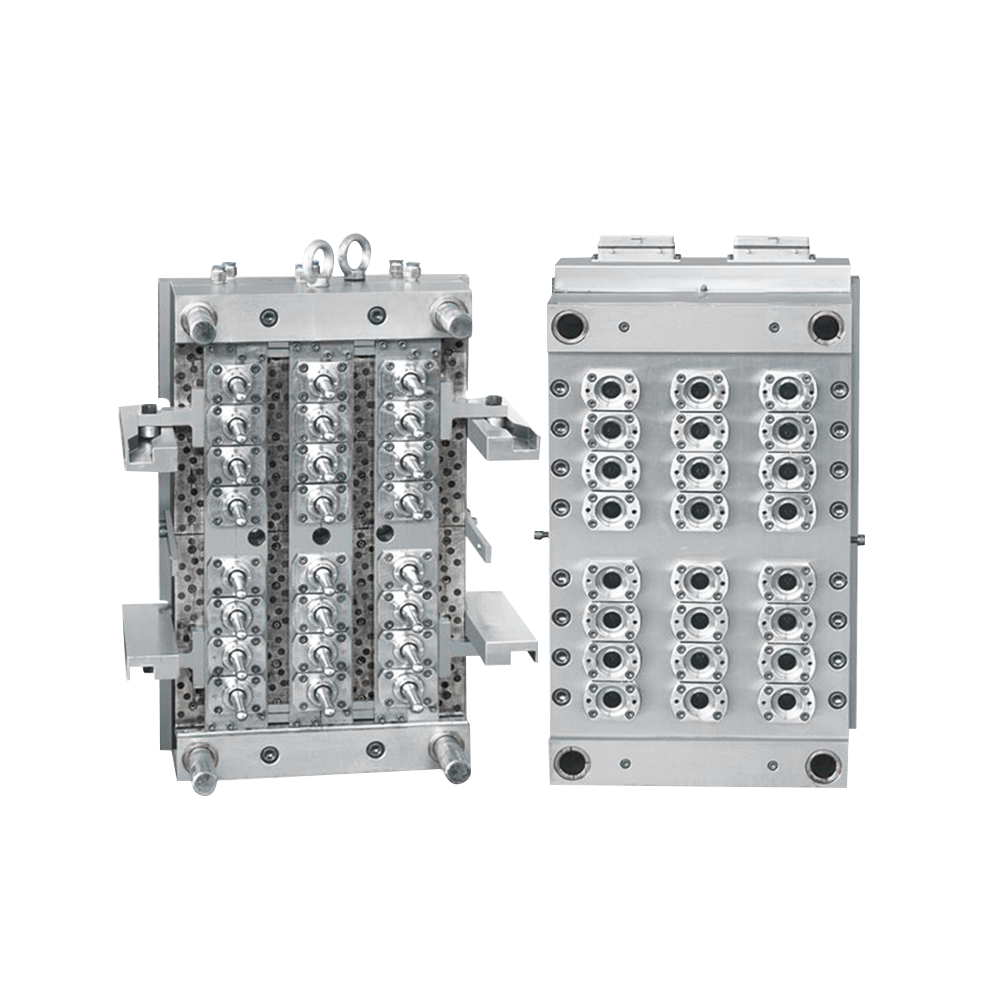

Preform Mould Factory is also engaging with local communities to promote environmental awareness and sustainable practices. By partnering with schools, non-profit organizations, and other local entities, these factories are helping to foster a culture of sustainability.

Sustainability is an ongoing journey, and Preform Mould Factory is committed to continuous improvement. They are constantly evaluating their processes and looking for new ways to reduce their environmental impact.

The sustainability efforts of OEM preform blow molding don't stop at their operations. They are also working with their suppliers to ensure that the entire supply chain is adopting green practices.

Preform Mould Factory is innovating in their product designs to make them more sustainable. This includes designing products that are easier to recycle or have a longer lifespan, thereby reducing waste.

Adhering to environmental regulations is a must for any industry. Preform Mould Factory is not only complying with existing regulations but also anticipating future requirements to stay ahead of the curve.

Transparency is key to sustainability. Preform Mould Factory is increasingly reporting its environmental performance to the public, allowing for greater accountability and trust.

The transition to green practices in the manufacturing sector is not just a trend but a necessity for the survival of our planet. Preform Mould Factory is playing a crucial role in this transition by adopting sustainable practices and setting an example for others to follow. As these factories continue to innovate and improve, they are not only contributing to a healthier environment but also to the economic viability of sustainable manufacturing.

English

English عربى

عربى Español

Español