A Deep Dive into Preform Mould Factory Technology

May 17,2024

Sale Cheap Preform Blowing Injection Mould Factory

The world of manufacturing is continuously advancing, and one sector that has seen significant innovation is the Preform Mould Factory industry. Preform moulds are essential components in the production of plastic bottles and containers, playing a crucial role in the packaging industry. This article will take a deep dive into the technology behind Sale Preform Blowing operations, exploring the processes, materials, and innovations that are shaping the future of this vital sector.

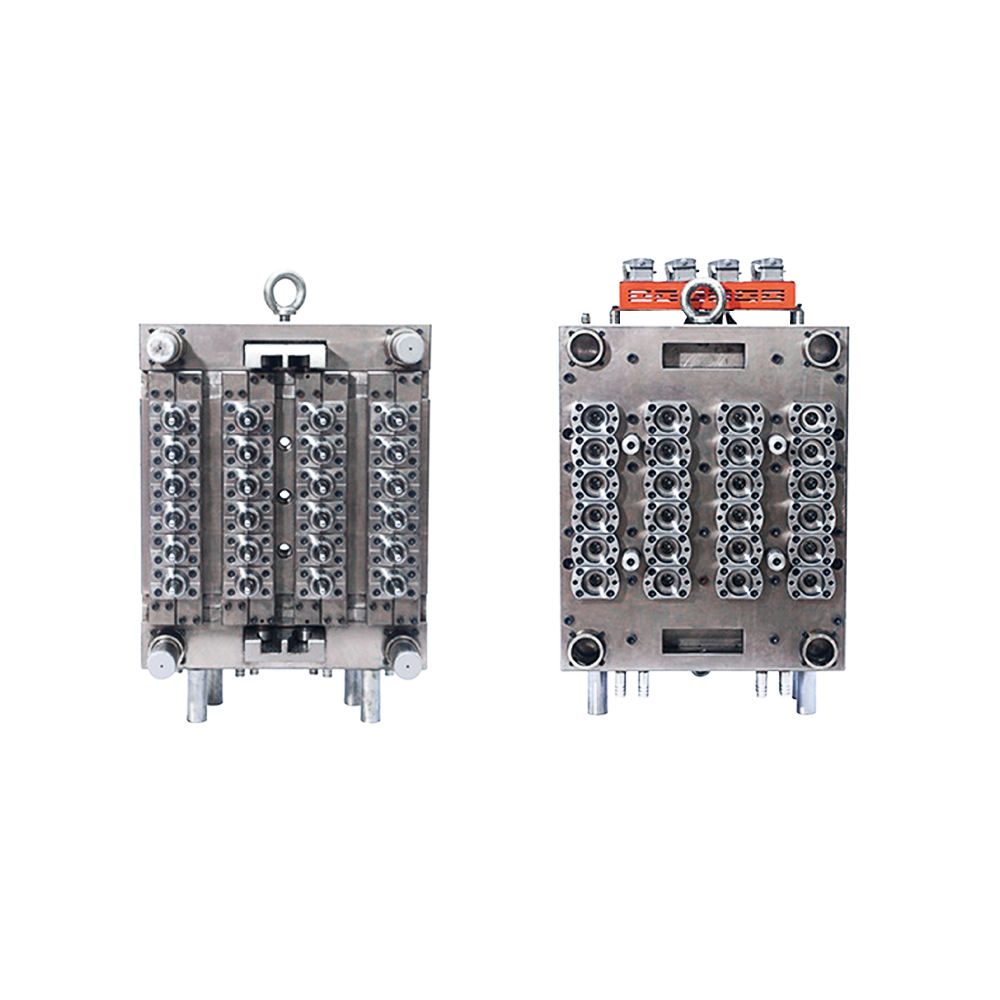

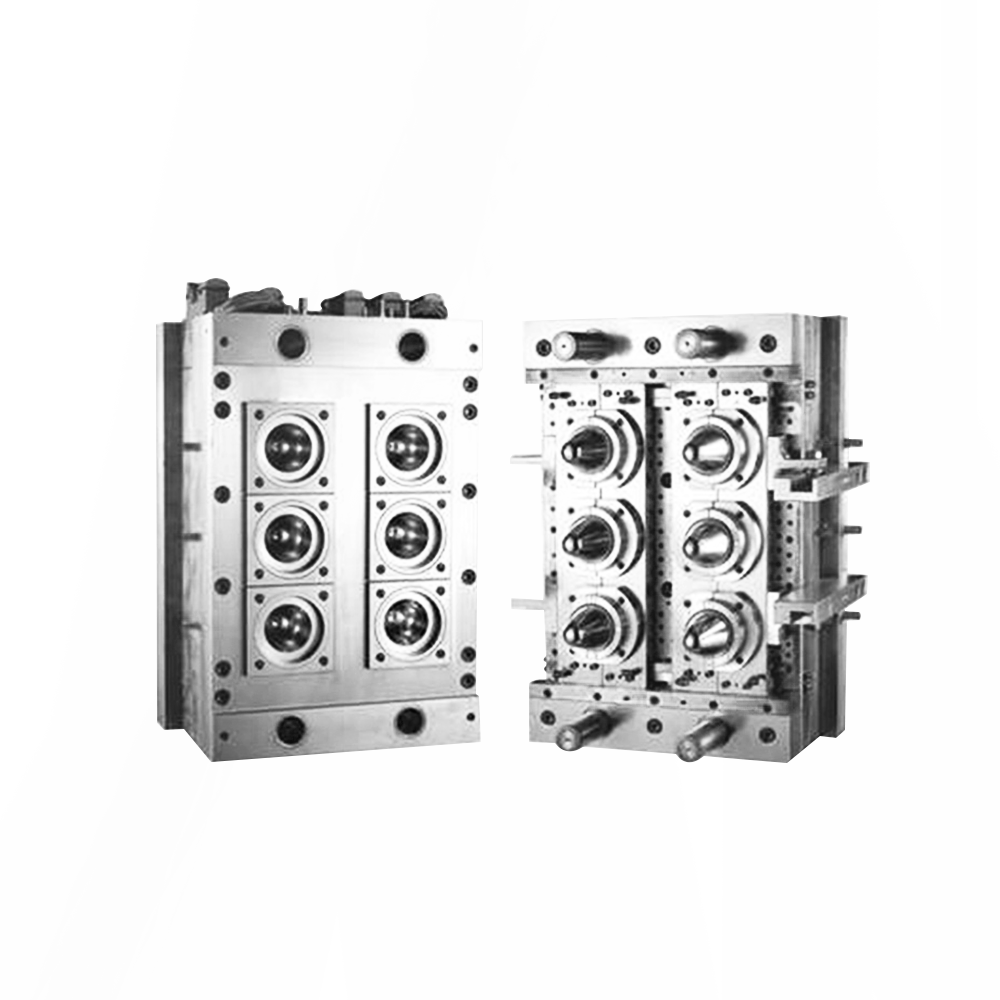

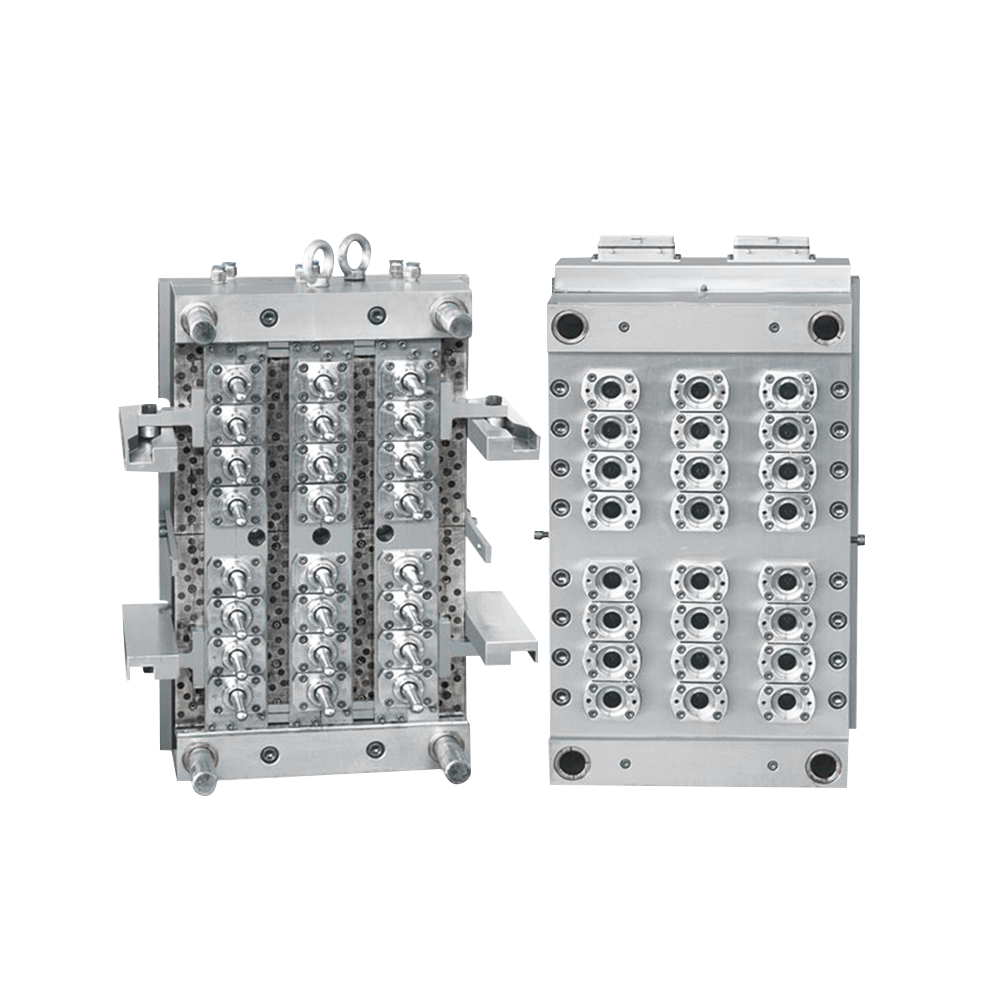

To comprehend the technology of a Preform Mould Factory, it is essential to understand what preform moulds are. Preform moulds are precision tools used in the injection moulding process to shape preforms, which are the initial forms of plastic bottles before being blown into their shape.

Preform Mould Factory is where these moulds are designed, manufactured, and tested. They are responsible for creating high-quality moulds that meet the exacting standards of the packaging industry, ensuring that the products are both functional and aesthetically pleasing.

The technology behind the Preform Mould Factory involves the selection of appropriate materials for the moulds. Steel alloys with high hardness and durability are typically used to withstand the pressures and temperatures involved in the injection moulding process.

The design and engineering phase is where the technology of Preform Mould Factories truly shines. Advanced computer-aided design (CAD) software is used to create detailed blueprints of the moulds, which are then engineered to ensure better performance and longevity.

The manufacturing process in a Cheap Preform Injection is highly technical and involves several stages, including cutting, grinding, and polishing the moulds to achieve the desired level of precision. This process requires cutting-edge machinery and skilled technicians.

Once the moulds are manufactured, they undergo rigorous quality control and testing to ensure they meet the Preform Mould Factory's high standards. This step is critical to guarantee the consistency and reliability of the preforms produced.

The Preform Mould Factory industry is not static; it is constantly evolving with new technologies. Innovations such as 3D printing and nanotechnology are being explored to improve the efficiency and capabilities of preform moulds.

The integration of automation and robotics in Preform Mould Factories has significantly increased productivity and reduced the potential for human error. Automated systems can precisely control the manufacturing process, resulting in higher-quality moulds.

Preform Mould Factory is also focusing on sustainability, with many adopting technologies that reduce waste and energy consumption. The use of recycled materials and energy-efficient machinery is becoming more common.

To keep up with the rapid advancements in technology, Preform Mould Factory invest heavily in the training and skill development of their workforce. This ensures that the team is equipped to handle the machinery and software.

With the advent of advanced technology, Preform Mould Factory can now offer a higher degree of customization and personalization for their clients. This allows for the production of unique preforms that cater to specific market needs.

Despite the technological advancements, Preform Mould Factory face challenges such as material costs and market competition. They are addressing these issues through continuous research and development, as well as by forming strategic partnerships.

Looking ahead, Preform Mould Factory is expected to continue leveraging technology to improve its processes. This includes the adoption of Industry 4.0 principles, which focus on smart manufacturing and data analytics.

As the demand for high-quality packaging solutions grows globally, Preform Mould Factory is expanding its reach to new markets. This expansion is facilitated by advancements in technology that allow for efficient production at scale.

In conclusion, the technology within Preform Mould Factory is a dynamic and ever-evolving field. From the materials used to the manufacturing processes and the quality control, every aspect is driven by technological advancements. As the industry continues to innovate, Preform Mould Factories will play a pivotal role in meeting the packaging needs of a diverse range of products.

English

English عربى

عربى Español

Español