The Impact of Preform Mould Factory on the Global Packaging Industry

May 24,2024

Sale Cheap Preform Mould Pet Mini Injection Molding Factory

The global packaging industry is a dynamic and ever-changing sector that plays a crucial role in the production and distribution of goods. One of the key components in this industry is the Preform Mould Factory, which has a significant impact on the design, production, and sustainability of packaging materials. This article will explore the various ways in which the Sale Pet Injection Molding is influencing the global packaging industry.

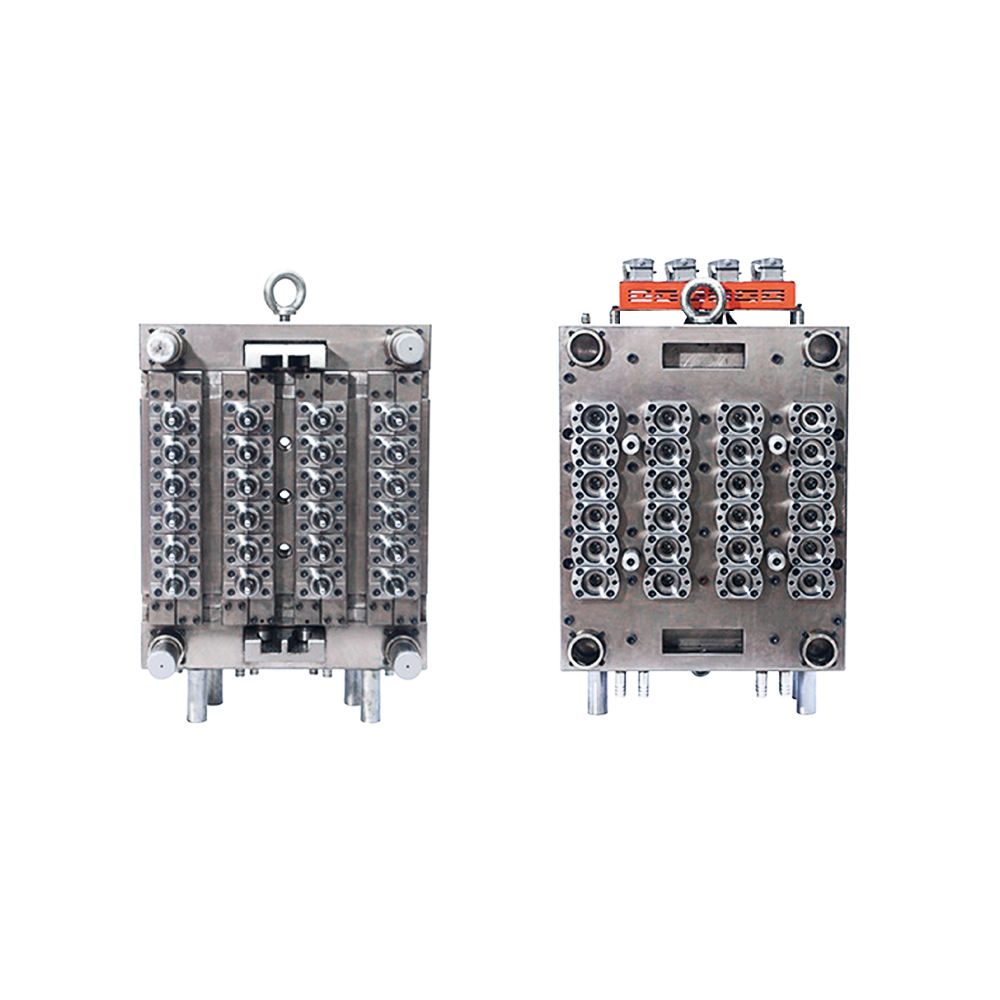

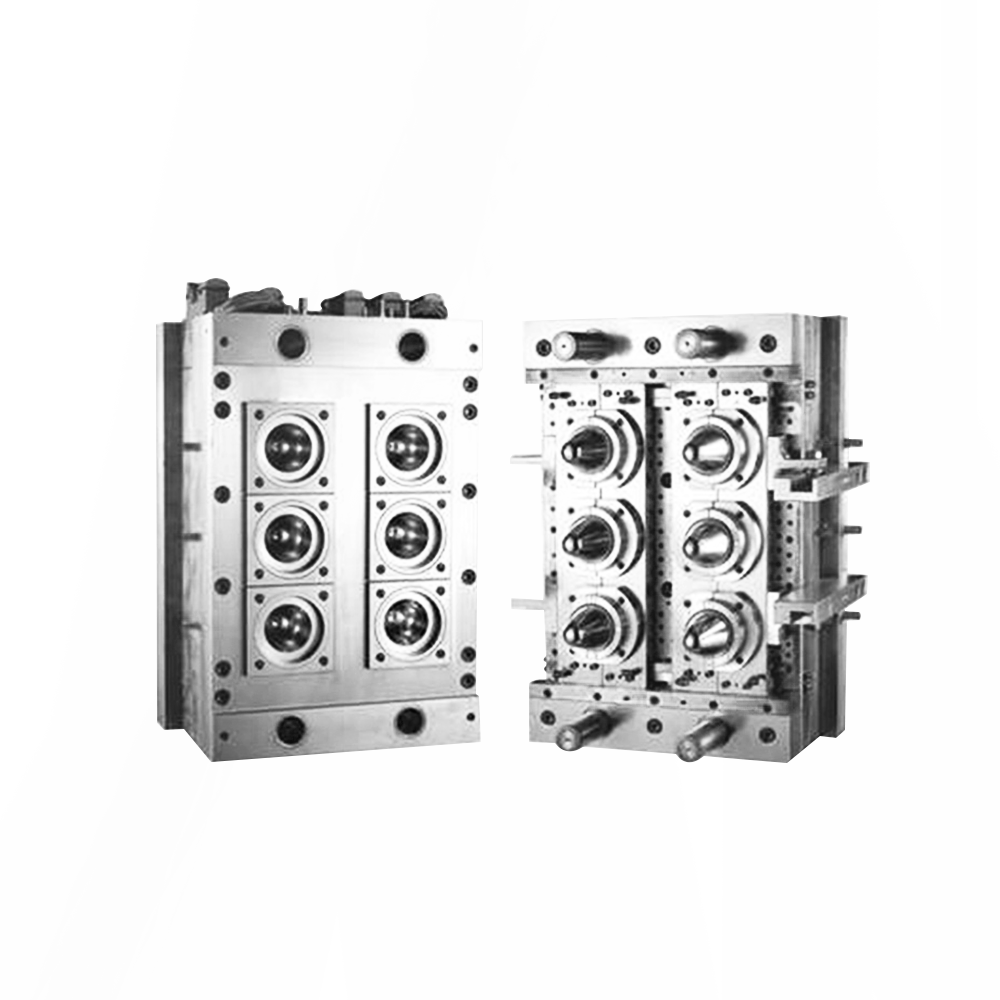

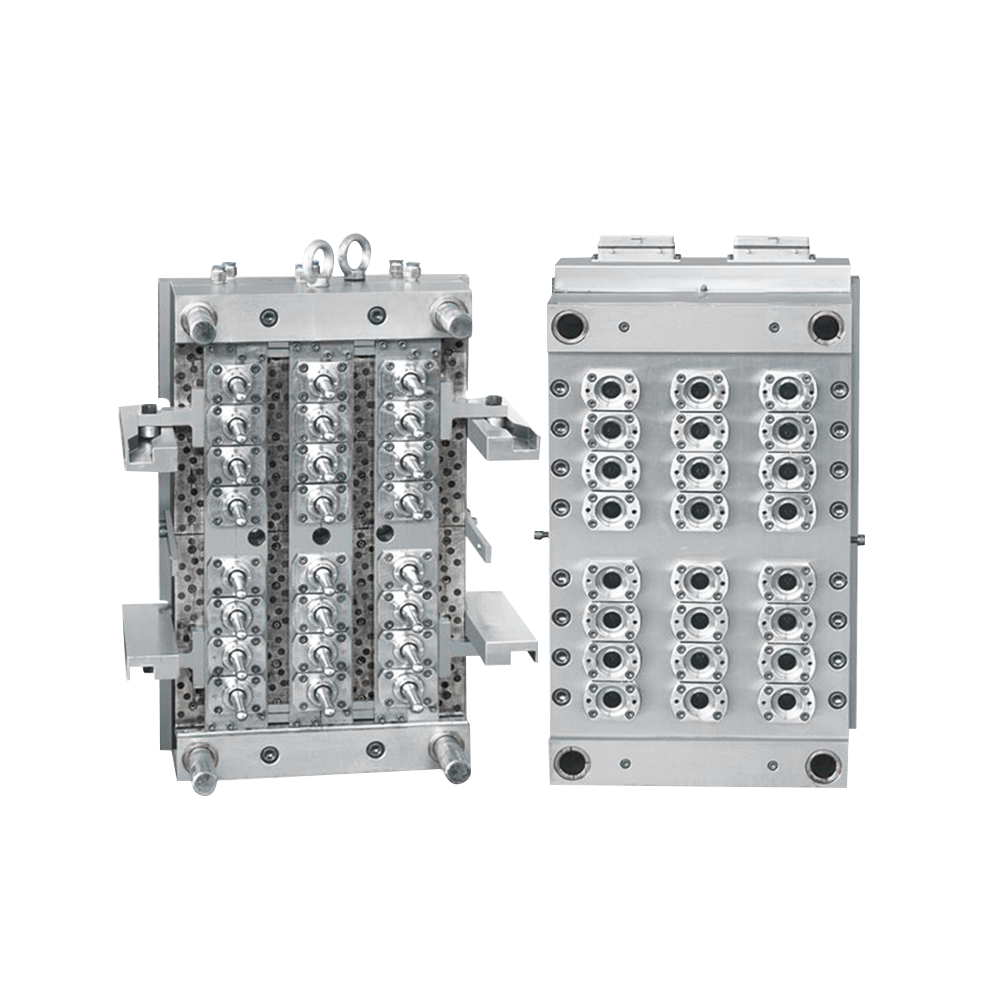

Preform Mould Factory is at the forefront of innovation when it comes to the design of preform moulds. These factories are constantly developing new technologies and techniques to create more efficient and effective moulds that can be used for a wide range of packaging applications. The use of advanced materials and computer-aided design (CAD) software allows these factories to produce moulds with intricate details and complex geometries that were previously impossible to achieve.

The ability of Preform Mould Factory to create customised moulds has had a profound impact on the packaging industry. Manufacturers can now work closely with these factories to design and produce packaging that is tailored to their specific needs. This level of customization allows for greater personalization of products, which can help to differentiate them in a crowded marketplace.

Preform Mould Factory has significantly improved the production capabilities of the packaging industry. By using cutting-edge machinery and automation, these factories can produce large quantities of high-quality preforms with a high degree of precision. This has led to increased efficiency and reduced production times, which in turn has helped to lower costs for manufacturers.

The environmental impact of packaging has become a major concern for both consumers and manufacturers. Preform Mould Factories are playing a key role in addressing these concerns by developing moulds that can be used to produce packaging made from sustainable materials. These factories are also focusing on reducing waste and energy consumption during the production process, which is helping to make the packaging industry more environmentally friendly.

Preform Mould Factory is committed to maintaining the standards of quality control and assurance. By implementing rigorous testing and inspection procedures, these factories can ensure that every preform mould meets the exacting standards required by the packaging industry. This focus on quality helps to reduce the risk of defects and ensures that packaging products are consistently reliable.

The expertise and capabilities of Preform Mould Factory can provide a significant competitive advantage for manufacturers. By partnering with these factories, manufacturers can access the technologies and innovations in preform mould design and production. This can help them stay ahead of their competitors and offer their customers packaging solutions that are better in terms of quality, functionality, and sustainability.

The economic impact of Preform Mould Factories should not be underestimated. These factories contribute to job creation and economic growth in the regions where they are located. They also play a vital role in the supply chain, providing essential components for the packaging industry that support the production of a wide range of goods.

The Cheap Mini Injection Molding sector is continuously investing in research and development to stay ahead of the curve. This has led to numerous technological advancements that have improved the functionality and efficiency of preform moulds. For example, the use of multi-cavity moulds has increased production capacity, while the incorporation of smart sensors has improved the monitoring and control of the production process.

Preform Mould Factories are not just limited to domestic markets; they have a global reach. By exporting their products and services, these factories are able to support the packaging needs of manufacturers around the world. This has helped to standardize packaging practices and improve the quality of products across international borders.

The Preform Mould Factory industry also plays a role in training and skill development. Many factories offer training programs for their employees, which not only improves the quality of their workforce but also contributes to the overall skill level of the industry.

The packaging industry is subject to rapid changes in consumer preferences and regulatory requirements. Preform Mould Factories must be highly adaptable to these changes to ensure that they can continue to meet the needs of their customers. This adaptability is a key factor in the success and sustainability of these factories.

English

English عربى

عربى Español

Español