The Role of Preform Mould Factory in the Packaging Industry

May 31,2024

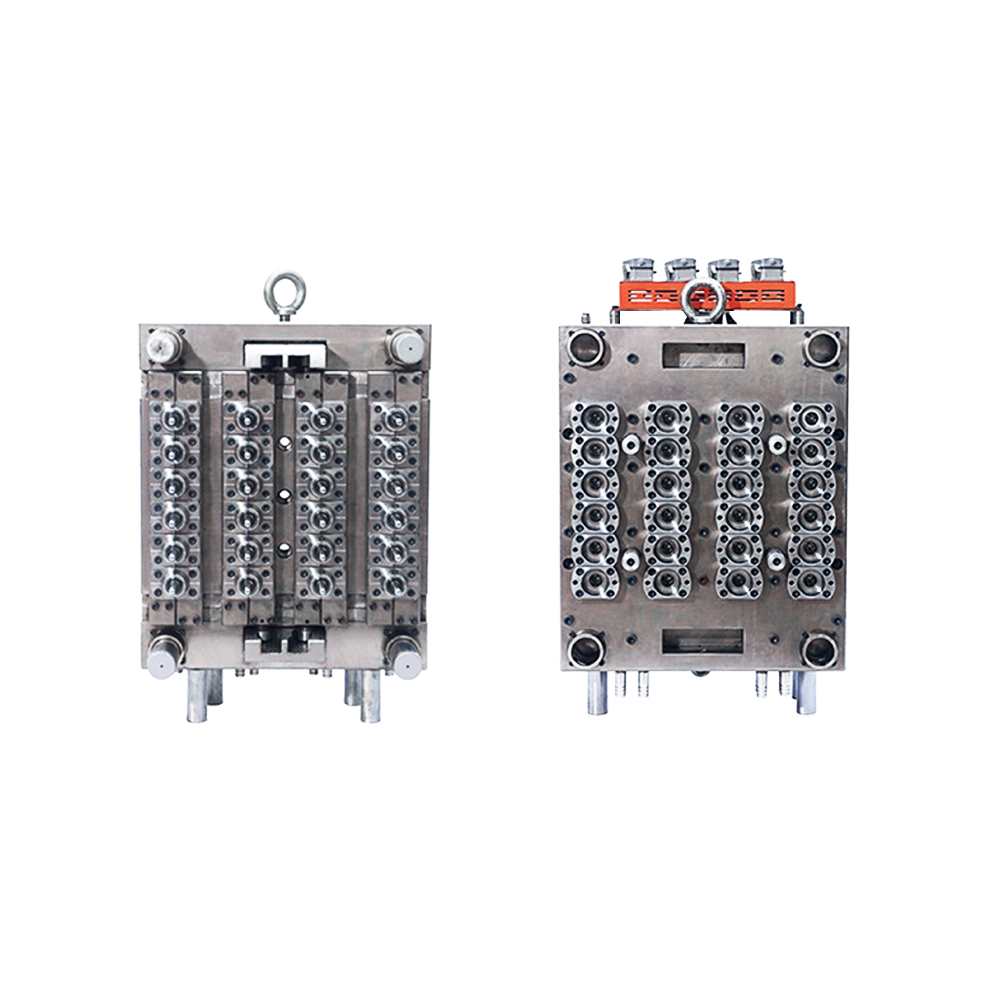

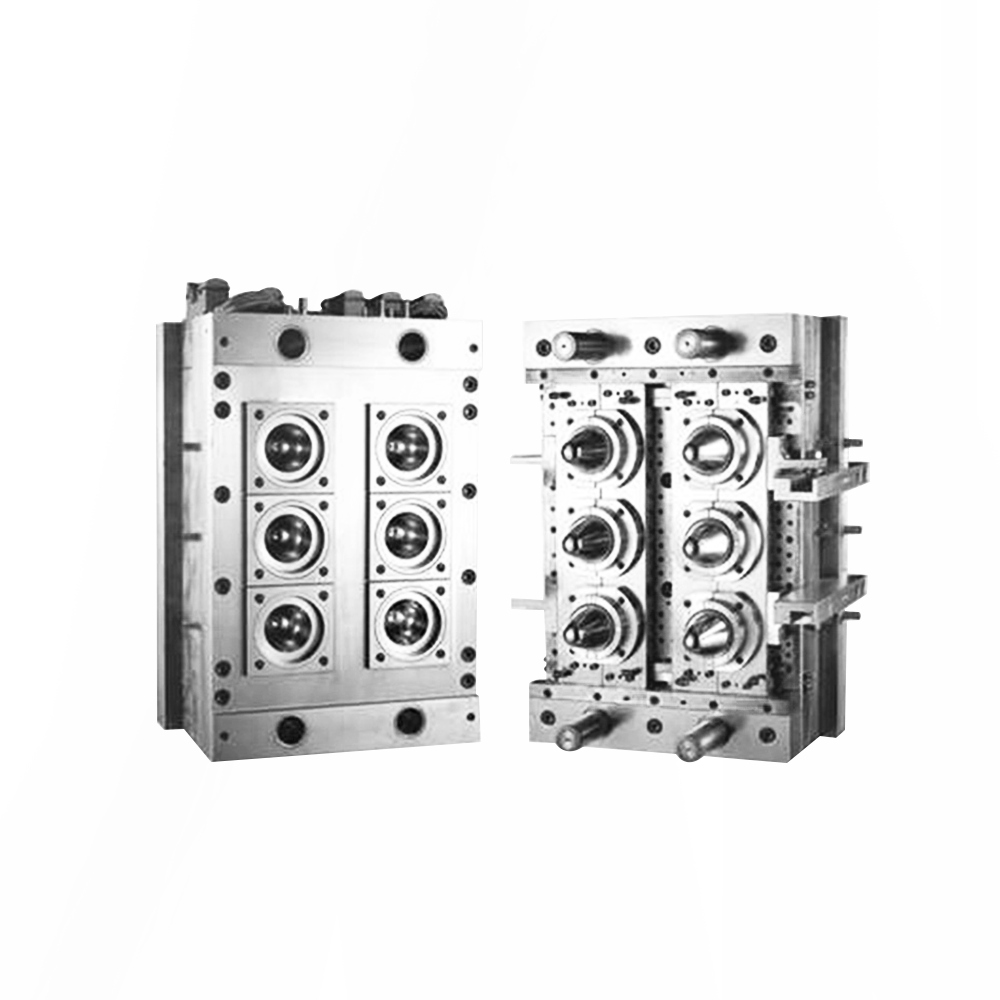

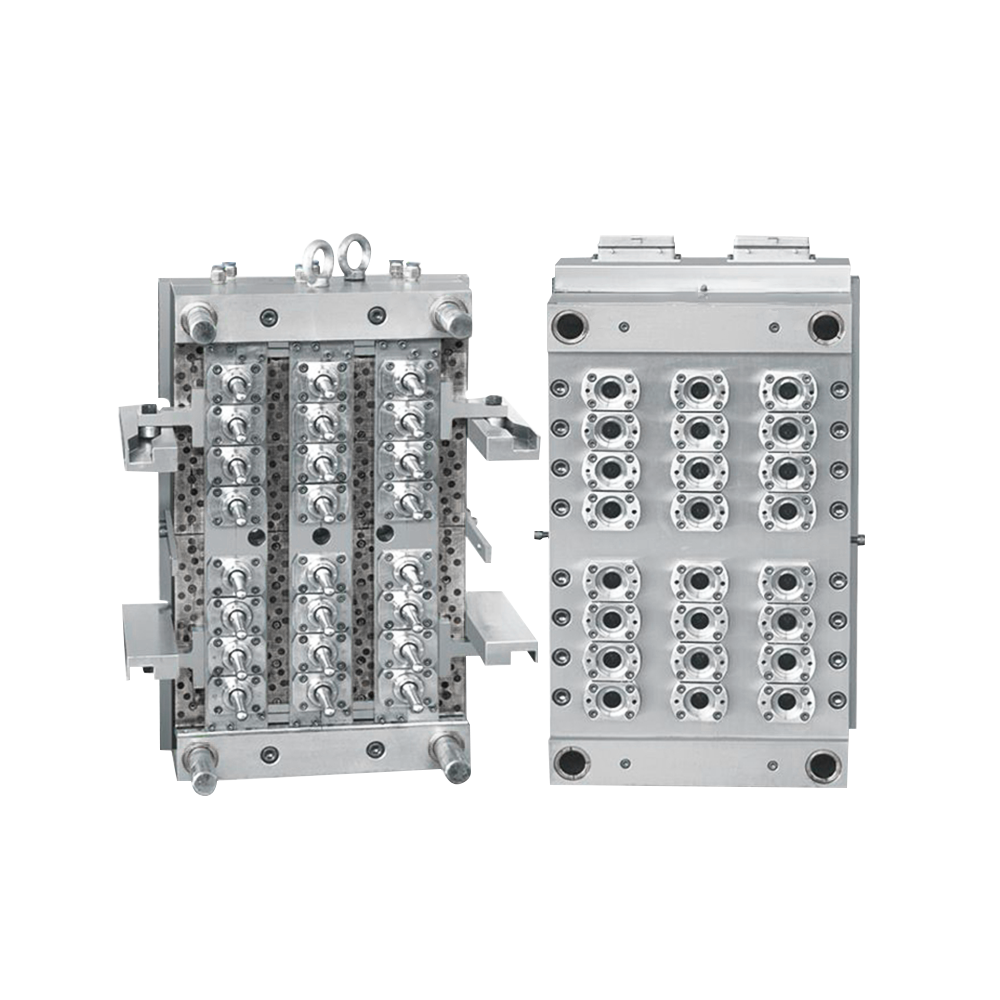

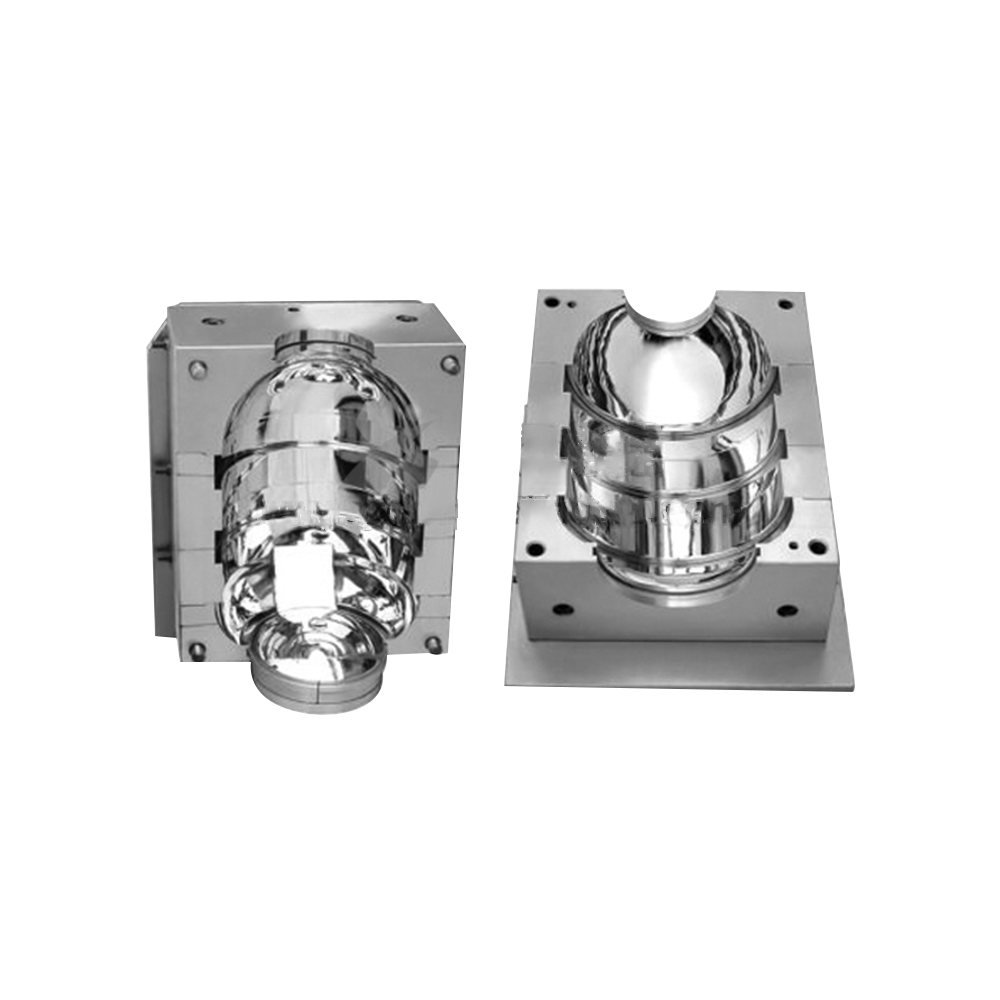

Custom OEM Plastic Injection Press Preform Mould Systems Factory

The packaging industry is a dynamic and essential sector that plays a crucial role in the production and distribution of goods. Within this industry, Preform Mould Factory holds a significant position due to its contribution to the creation of plastic preforms, which are the foundation for many types of packaging, particularly in the beverage industry. This article will explore the various roles that Preform Mould Factories play in the packaging industry, from innovation and design to sustainability and customer service.

Preform Mould Factory is at the forefront of innovation in the packaging industry. They are responsible for designing and manufacturing the moulds that give shape to the preforms, which are the forms of plastic bottles and containers. These factories invest heavily in research and development to create moulds that are not only functional but also aesthetically pleasing and innovative.

The design process in Custom Mould Systems involves a deep understanding of the client's needs and the use of the packaging. This ensures that the preforms produced are tailored to the specific requirements of the product being packaged.

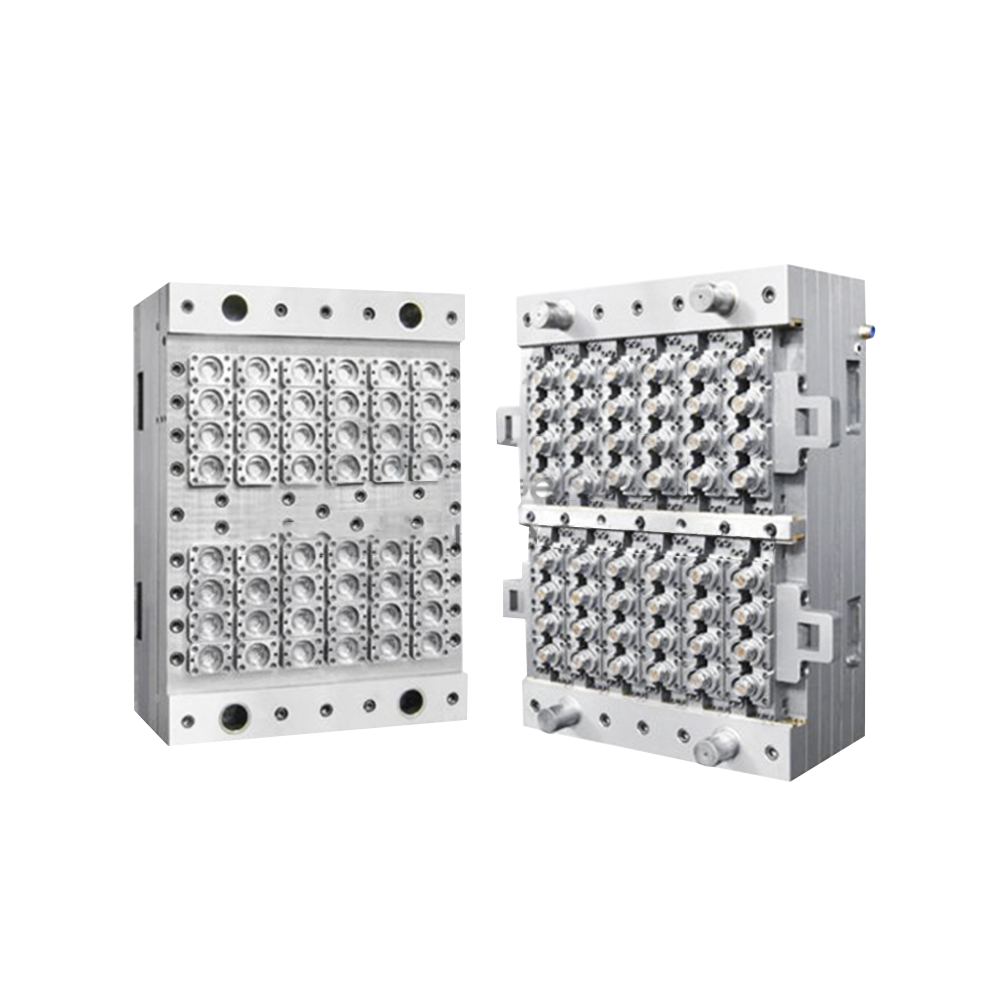

As technology advances, Preform Mould Factory is continuously improving its manufacturing processes. This includes the adoption of new materials, such as biodegradable plastics, and the implementation of advanced automation techniques to increase efficiency and precision.

Preform Mould Factory also plays a critical role in the prototyping stage. They work closely with clients to create sample moulds, allowing for testing and refinement before mass production begins.

A key role of the Preform Mould Factory is to ensure the quality of the preforms produced. This involves rigorous quality control measures that test the durability, structural integrity, and consistency of the moulds.

The factories are also responsible for ensuring that the moulds meet international standards and regulations, which is essential for the packaging industry as it operates on a global scale.

Quality assurance extends to the customer service provided by Preform Mould Factory. They offer support and troubleshooting assistance to clients, ensuring that the moulds perform as expected in the production process.

Preform Mould Factory is increasingly focusing on sustainability. They are developing moulds for preforms that use less material, are made from recycled content, or are designed for easy recycling.

These factories are also exploring the use of alternative materials that have a lower environmental impact, such as bioplastics and other eco-friendly options.

By focusing on sustainability, Preform Mould Factory is helping the packaging industry to reduce its carbon footprint and contribute to a circular economy.

One of the significant advantages of working with Preform Mould Factories is the level of customization they can offer. They can create moulds for a wide range of perform sizes, shapes, and designs, catering to the diverse needs of the packaging industry.

This flexibility allows clients to differentiate their products in the market, offering unique packaging solutions that can enhance brand recognition and consumer appeal.

Preform Mould Factory also provides the flexibility to adapt to changing market trends and consumer preferences, ensuring that its clients can respond quickly to shifts in demand.

By specializing in the production of preform moulds, Preform Mould Factory can offer competitive pricing to its clients. This cost-effectiveness is a significant benefit for the packaging industry, as it allows companies to manage their production costs more effectively.

The economies of scale achieved by OEM Plastic Injection Press also contribute to the affordability of their products, making high-quality packaging solutions accessible to a broader range of businesses.

Preform Mould Factory plays a multifaceted role in the packaging industry. They are not only the creators of the essential preforms that form the basis of many packaging solutions but also contribute to innovation, quality assurance, sustainability, customization, and cost-effectiveness. As the packaging industry continues to evolve, the role of Preform Mould Factories will remain pivotal in meeting the challenges of the future.

English

English عربى

عربى Español

Español