Custom China PET Preform Mold Services Offered by Blow Mould Factory

Jul 19,2024

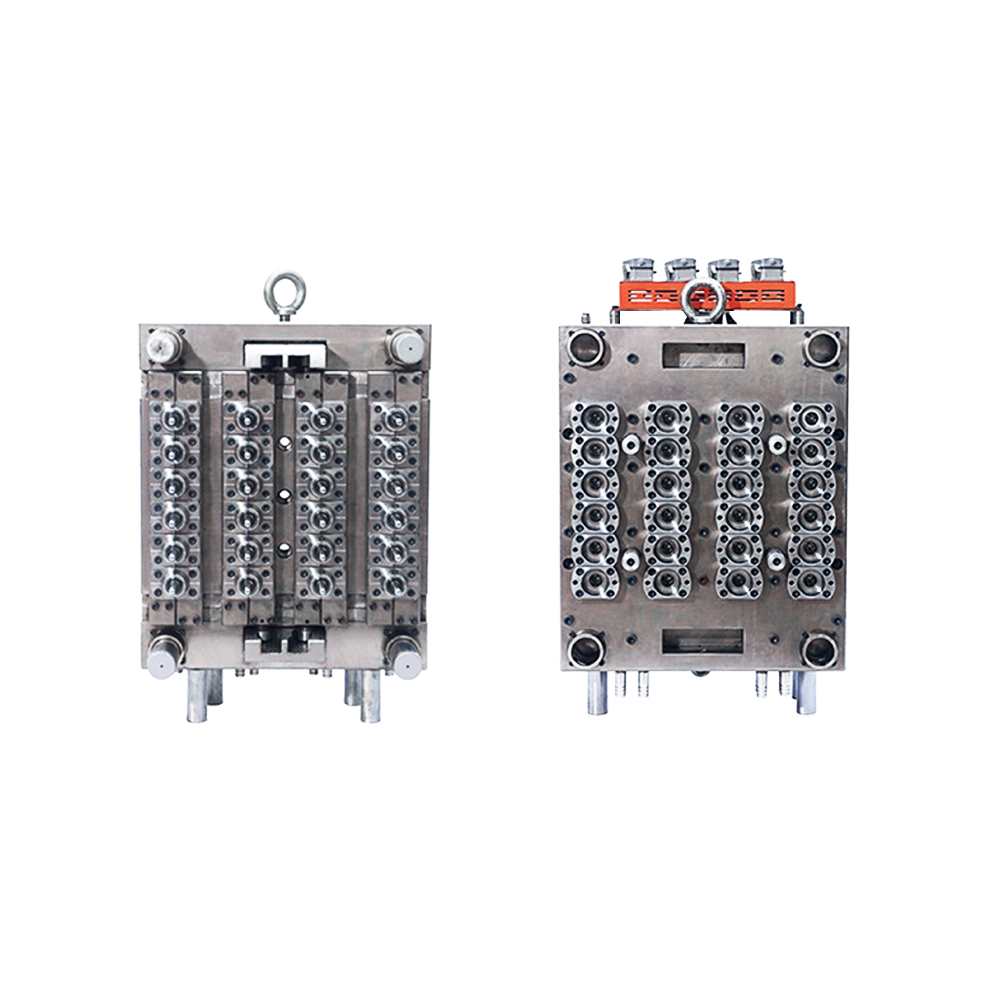

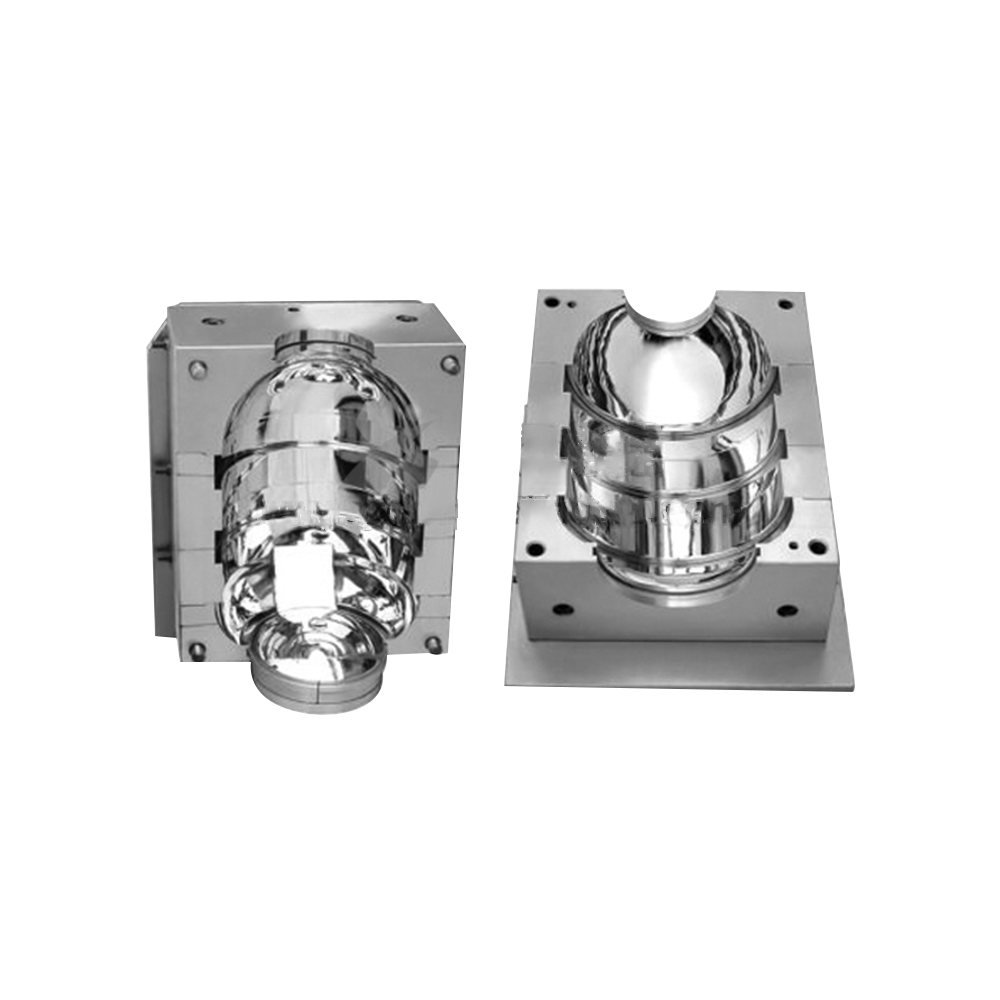

China Custom PET Preform Injection Mold Blow Mould Factory

In the realm of manufacturing and production, precision and reliability are paramount, especially when it comes to custom molds for PET preforms. China PET preform mold services provided by blow mould factory that are integral to meeting the diverse needs of industries ranging from beverage packaging to pharmaceuticals. This article explores the comprehensive offerings and capabilities of Custom PET Preform Injection in China, focusing on their expertise in delivering custom PET preform molds tailored to specific client requirements.

China PET preform mold services encompass the design, manufacturing, and customization of molds used in the production of PET (Polyethylene Terephthalate) preforms. These forms serve as the initial stage in the manufacturing process of PET bottles, jars, and containers widely used in the beverage, food, cosmetic, and pharmaceutical industries. Customization allows manufacturers to create preforms of various shapes, sizes, and specifications to meet the unique packaging needs of their products.

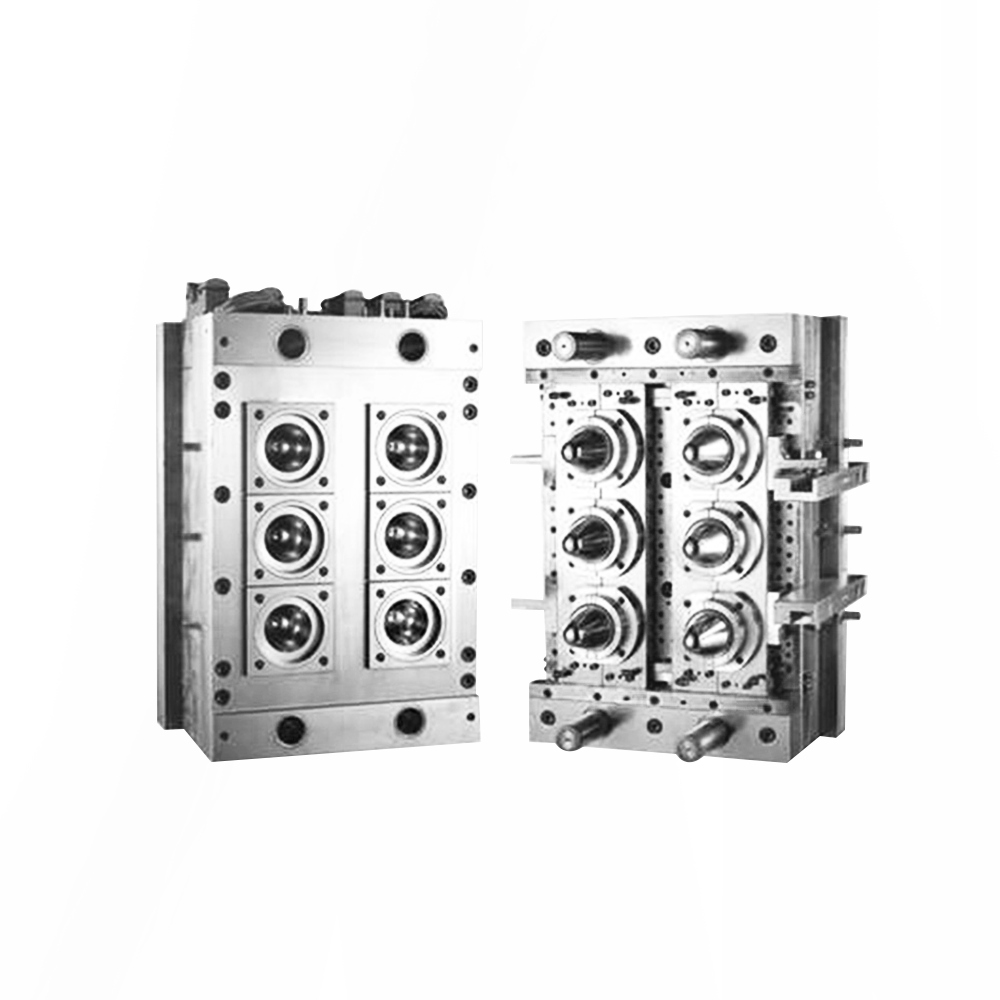

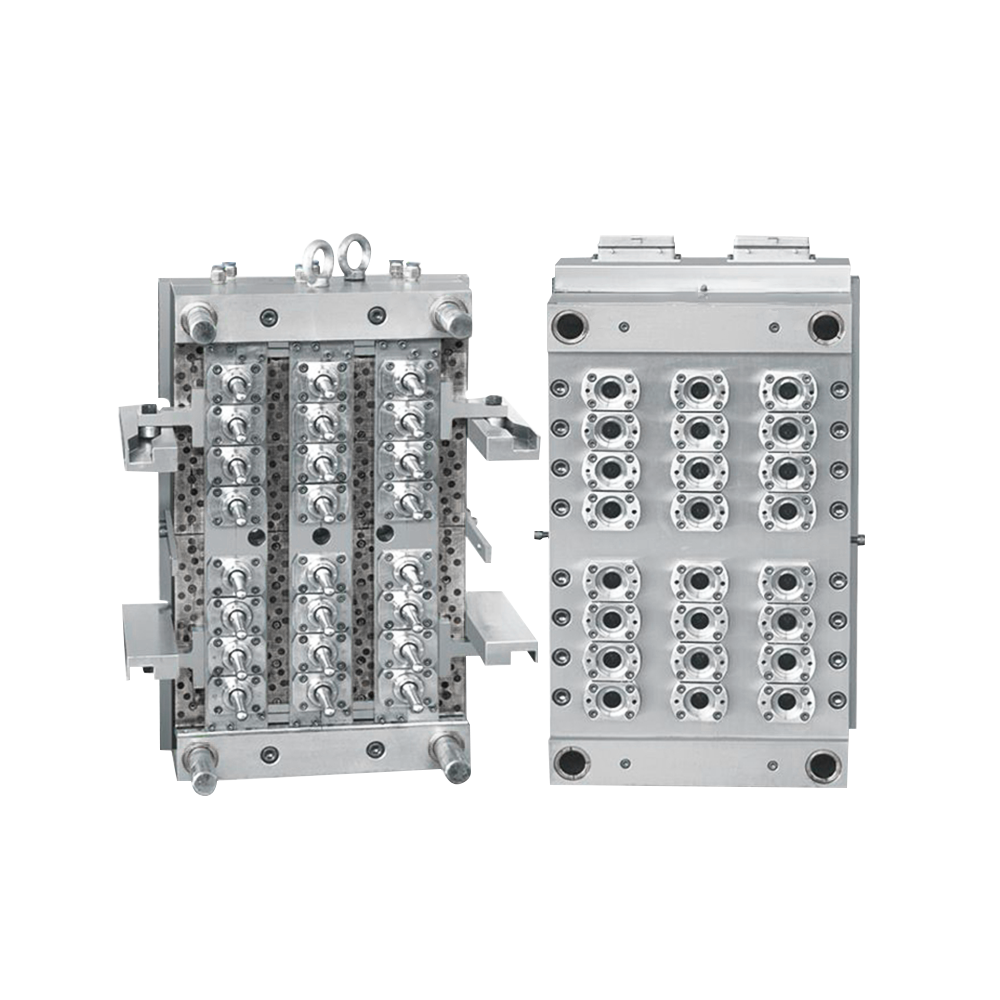

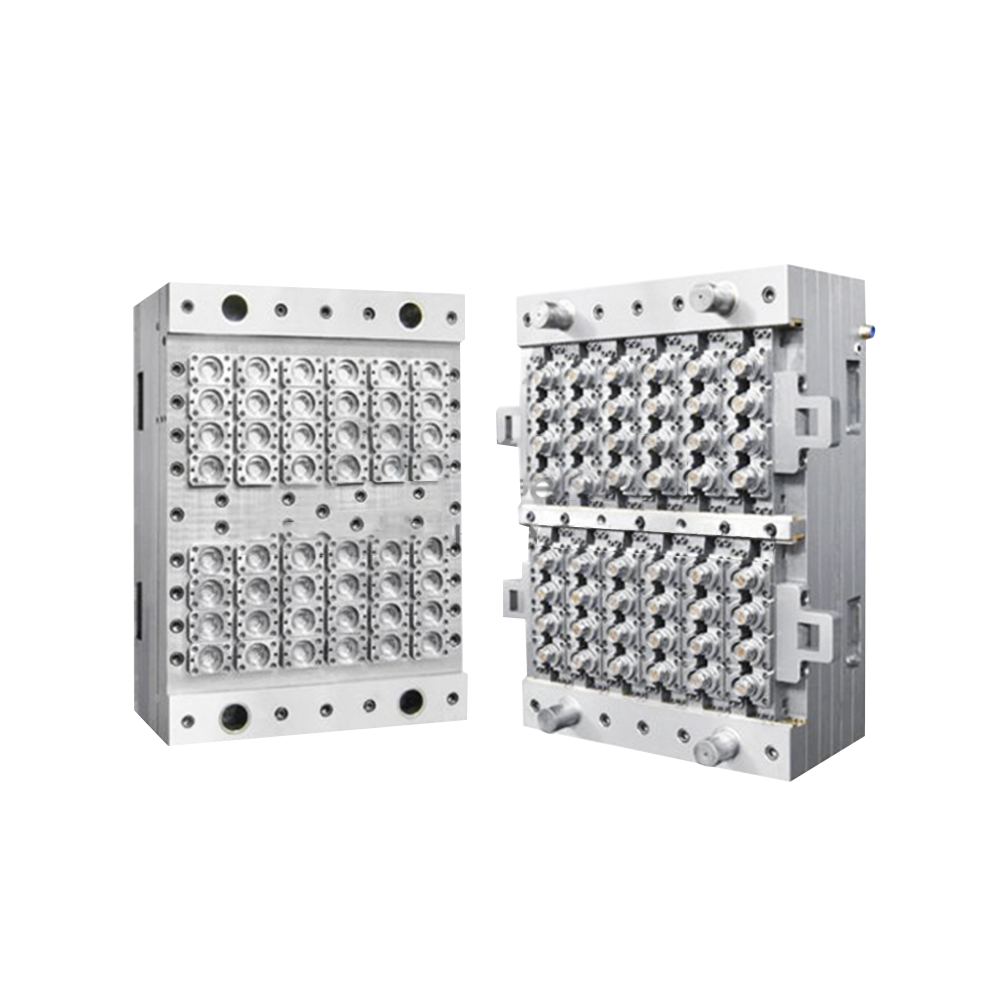

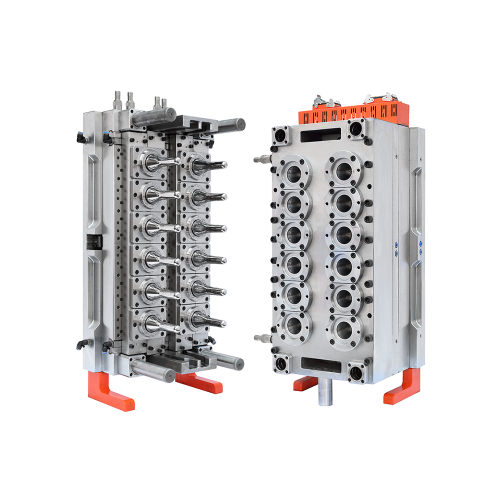

Blow mould factory in China plays a pivotal role in the production of China PET preform molds. These facilities are equipped with advanced technology and a skilled workforce capable of designing and fabricating molds to precise specifications. The expertise of the blow mould factory extends beyond manufacturing to include prototyping, testing, and refining molds to ensure ideal performance and durability in production environments.

One of the key advantages of China PET preform mold services offered by blow mould factory is their ability to customize molds according to client requirements. This customization may involve designing molds for specific bottle shapes, neck finishes, and wall thicknesses that meet industry standards and consumer preferences. Advanced CAD/CAM software and CNC machining capabilities enable precise customization, ensuring that each mold meets the exact specifications provided by the client.

Blow mould factory in China adheres to stringent quality assurance protocols throughout the manufacturing process of China PET preform molds. From material selection toinspection, every step is carefully monitored to guarantee the integrity and longevity of the molds. High-quality materials such as stainless steel and aluminum alloys are often used to ensure durability and resistance to wear and tear, thereby prolonging the lifespan of the molds and optimizing production efficiency.

Advancements in technology have significantly enhanced the capabilities of blow mould factory in China. Automated processes, including robotic machining and 3D printing, expedite mold production while maintaining precision and consistency. These technological advancements not only reduce production times but also improve the overall quality and reliability of custom PET preform molds.

The versatility of China PET preform mold services extends across various industries where PET packaging is prevalent. In the beverage industry, for example, custom molds enable manufacturers to produce PET bottles that are lightweight yet durable, ideal for carbonated drinks, water, juices, and energy drinks. Pharmaceutical companies benefit from China PET preform molds capable of producing containers that meet stringent regulatory requirements for drug packaging.

Blow mould factory in China adopts a collaborative approach when working with clients to develop custom PET preform molds. Close communication and feedback ensure that the mold design aligns with the client's production goals and quality standards. Prototyping and testing phases allow for adjustments and refinements to be made early in the process, reducing potential issues during full-scale production.

Environmental sustainability is a priority for many manufacturers utilizing PET packaging. China PET preform mold services offered by environmentally conscious blow mould factory focusing on optimizing material usage and reducing waste during production. Recycling initiatives and the use of eco-friendly materials contribute to reducing the environmental footprint associated with PET preform mold manufacturing.

In conclusion, China PET preform mold services offered by blow mould factory underscoring the country's prominence in manufacturing and innovation. These services provide essential capabilities for industries requiring customized PET packaging solutions, from beverages to pharmaceuticals. By leveraging advanced technology, expertise in mold design, and a commitment to quality, blow mould factory in China continue to meet the evolving needs of global markets. As demand for PET packaging grows, so too does the significance of reliable and adaptable China PET preform mold services offered by China's prominent blow mould factories.

English

English عربى

عربى Español

Español