China PET Preform Molds and the Environmental Impact of Blow Mould Factory

Jul 12,2024

China OEM PET Preform Injection Molding Blow Mould Factory

In the contemporary era of environmental consciousness, the manufacturing industry, particularly the Blow Mould Factory, is under increasing scrutiny to adopt sustainable practices. China, with its advanced manufacturing capabilities, has taken significant strides in this direction, especially with the development and use of China PET Preform Molds. These molds are not just tools for production; they are emblematic of the industry's commitment to reducing its ecological footprint.

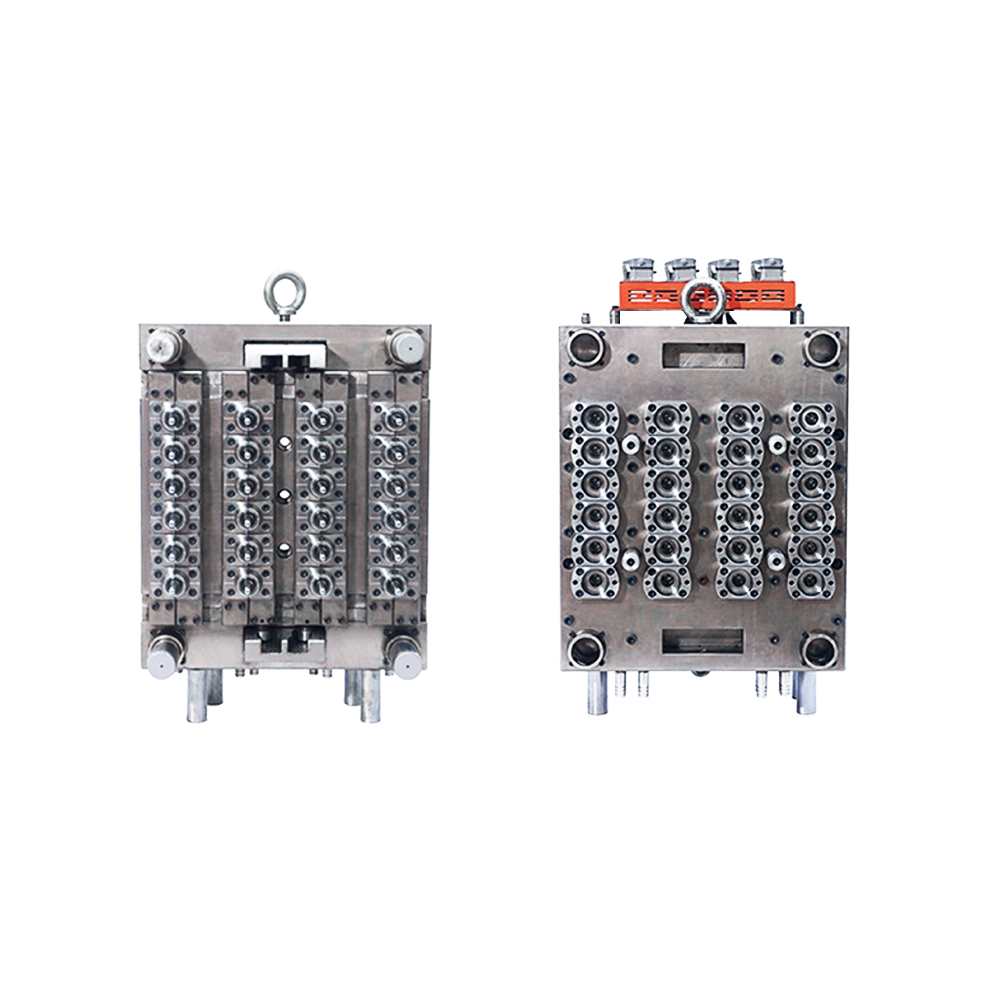

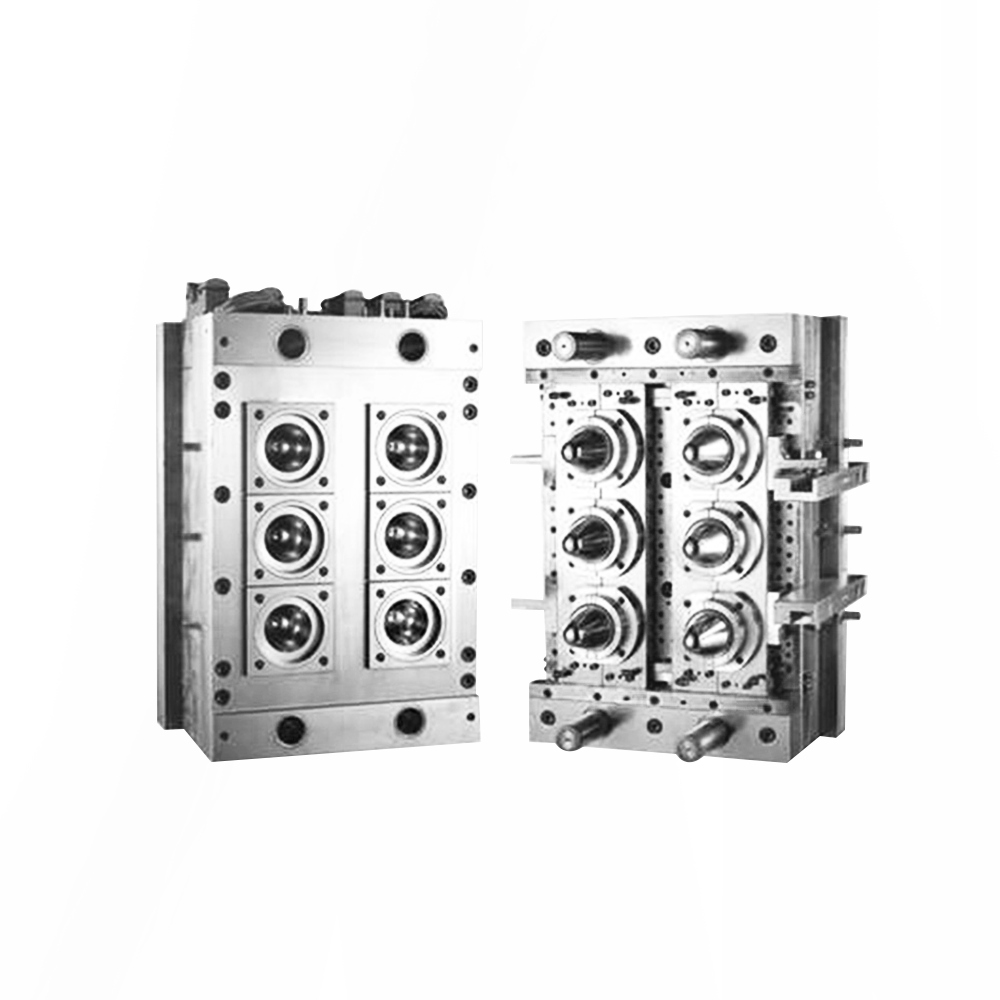

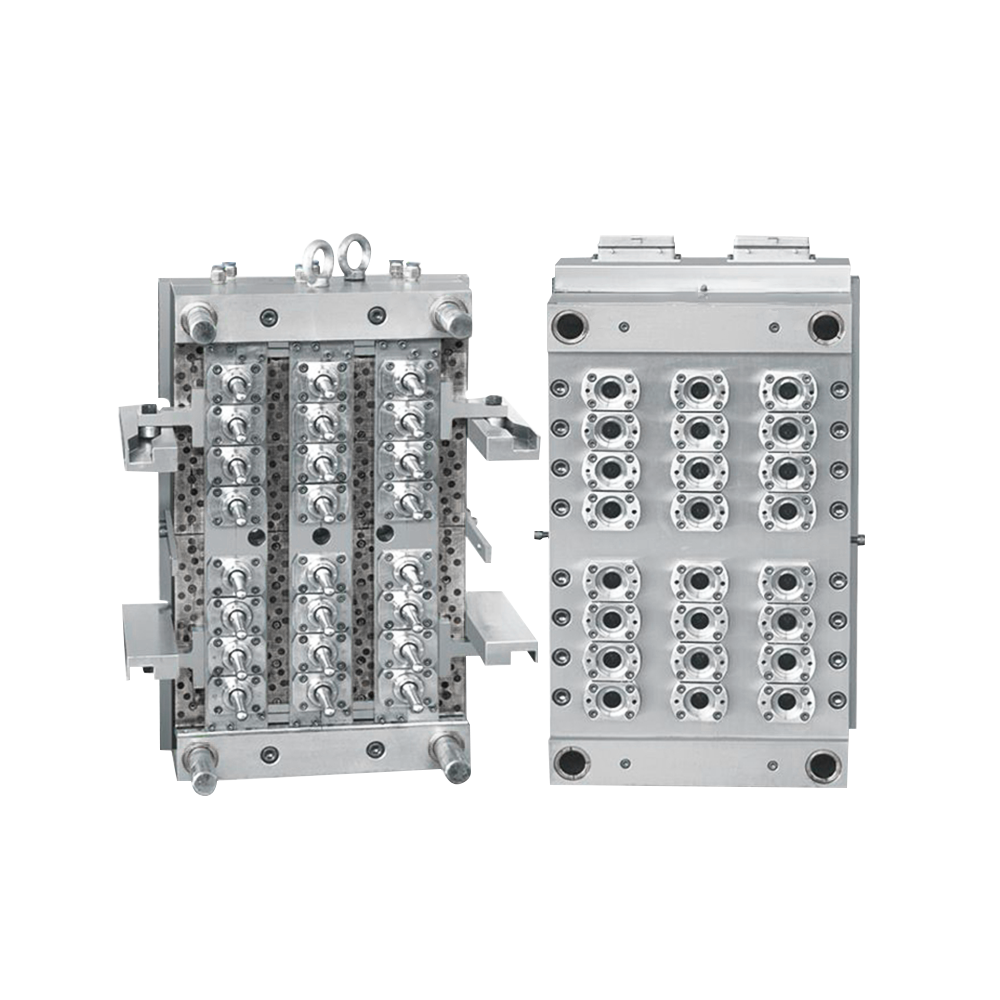

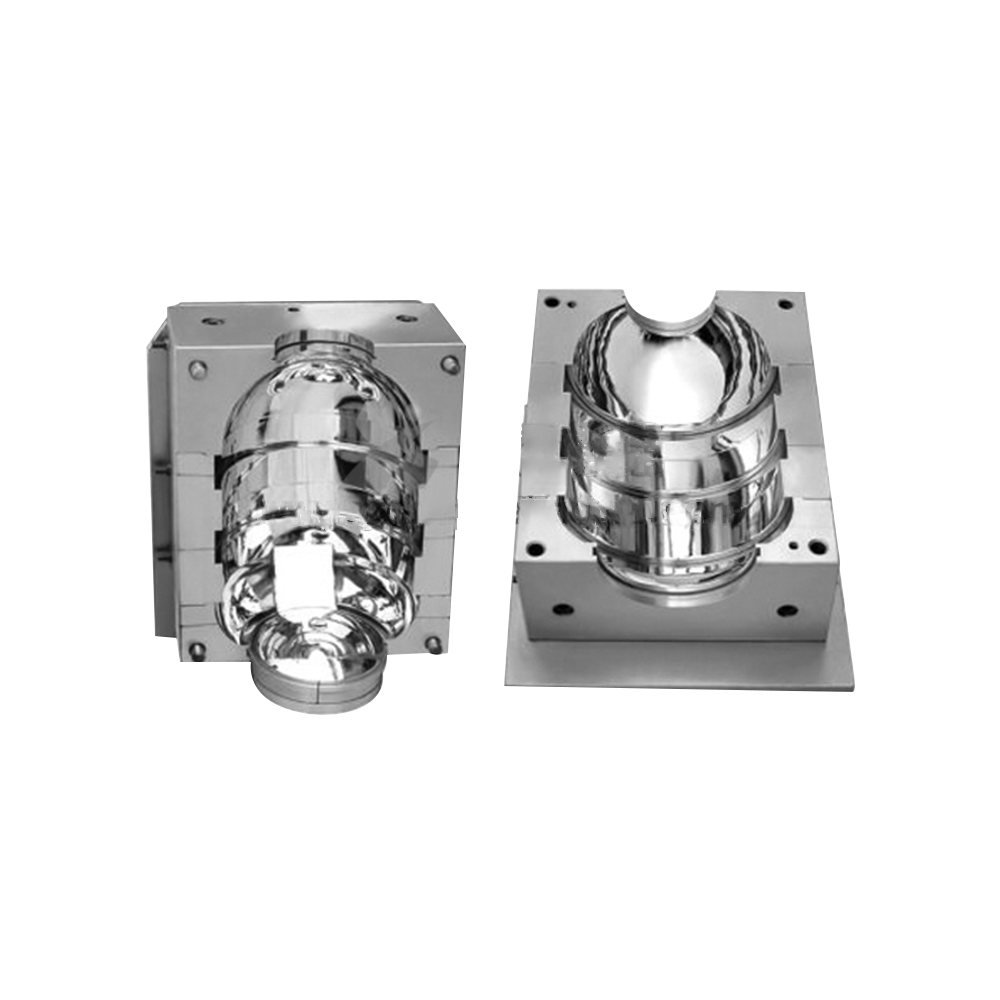

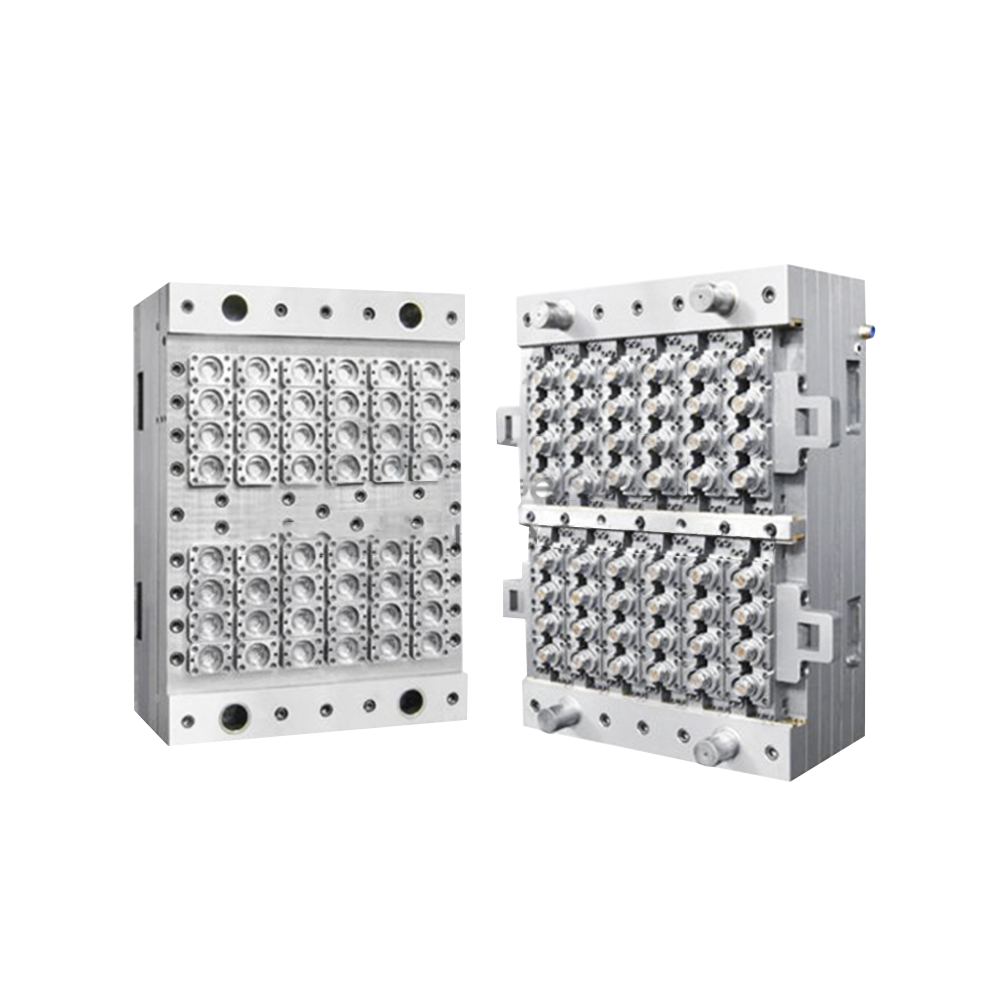

The Role of China PET Preform Molds in Sustainable Manufacturing. China PET Preform Molds are precision-engineered tools designed to produce PET preforms, the initial stage of plastic bottles and containers. These molds are crafted with high-quality materials that ensure durability and longevity, reducing the need for frequent replacements and thereby reducing waste. The design of these molds also incorporates features that reduce material usage, resulting in lighter and more efficient preforms.

Innovations in Blow Mould Factory Practices. OEM Preform Injection Molding in China has integrated these performed molds into their production lines, leveraging the technologies to enhance the efficiency of the blow molding process. The use of energy-efficient machinery and renewable energy sources has become a norm in these factories, significantly reducing the carbon footprint of the manufacturing process.

Moreover, the Blow Mould Factory is investing in research and development to create new materials and processes that further decrease the environmental impact. For instance, the development of biodegradable or recyclable materials for preform production is a key area of focus.

Environmental Standards and Certifications. Adherence to stringent environmental standards is a hallmark of Blow Mould Factory in China. These factories are often certified to international environmental management standards such as ISO 14001, which ensures a systematic approach to environmental responsibility. The use of China PET Preform Molds in these factories is a testament to their commitment to these standards.

Waste Reduction and Recycling Initiatives. Waste management is a critical aspect of the Blow Mould Factory's operations. By using China PET Preform Molds, these factories are able to produce preforms with less material waste. Additionally, many factories have implemented recycling programs for both the preforms and the molds themselves, ensuring that materials are repurposed rather than discarded.

The Impact on the Supply Chain. The use of China PET Preform Molds in Blow Mould Factories has a ripple effect throughout the supply chain. Suppliers are encouraged to adopt sustainable practices, and customers are offered products that align with their environmental values. This creates a virtuous cycle of environmental responsibility that extends beyond the factory walls.

Looking ahead, the role of China PET Preform Molds in Blow Mould Factory is set to expand. As global awareness of environmental issues grows, the demand for sustainable packaging solutions will continue to rise. The factories that embrace these molds are well-positioned to meet this demand, offering innovative and eco-friendly alternatives to traditional packaging methods.

The integration of China PET Preform Molds within Blow Mould Factory is a clear indication of the industry's pivot toward sustainability. These factories are not just producing packaging; they are shaping the future of environmentally friendly manufacturing. As the world moves towards a greener economy, the role of these factories and their molds will only grow in significance, ensuring that the packaging industry remains both functional and environmentally responsible.

English

English عربى

عربى Español

Español