The role of China PET Preform Mold and Blow Mould Factory in environmentally friendly packaging

Jul 05,2024

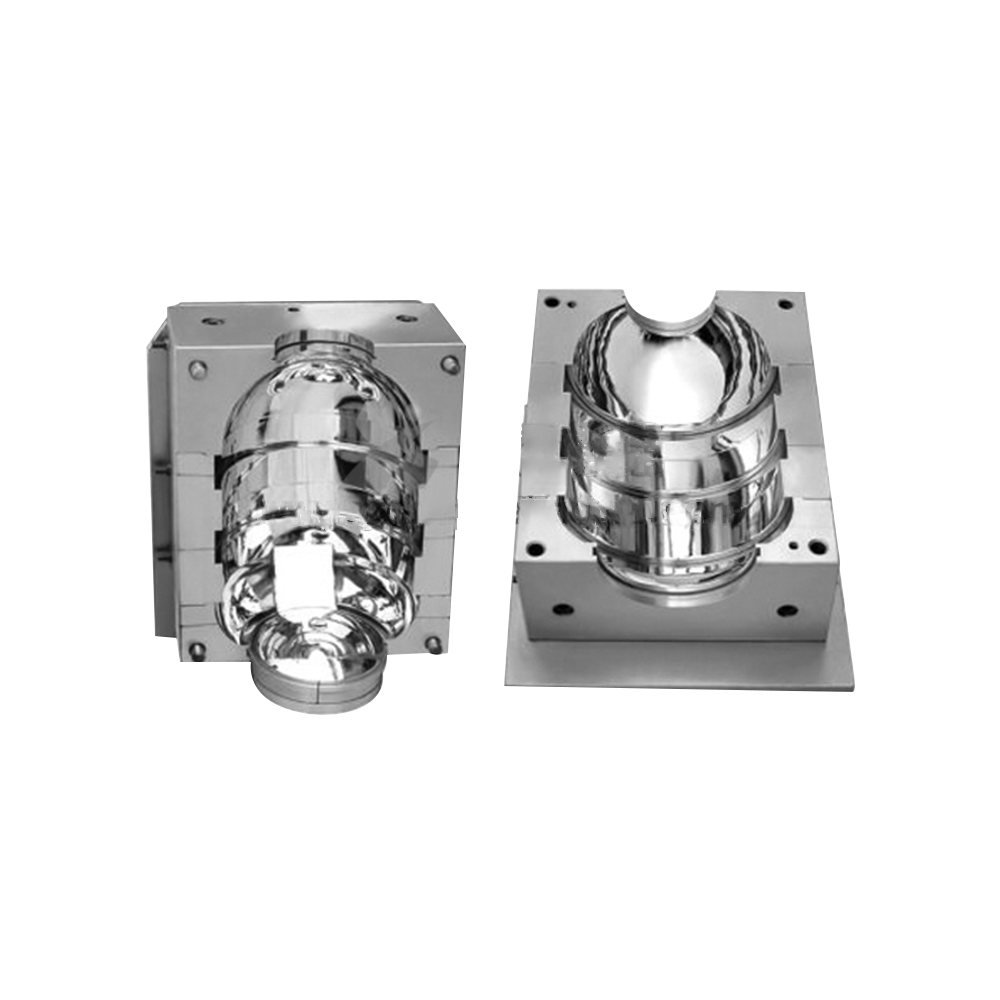

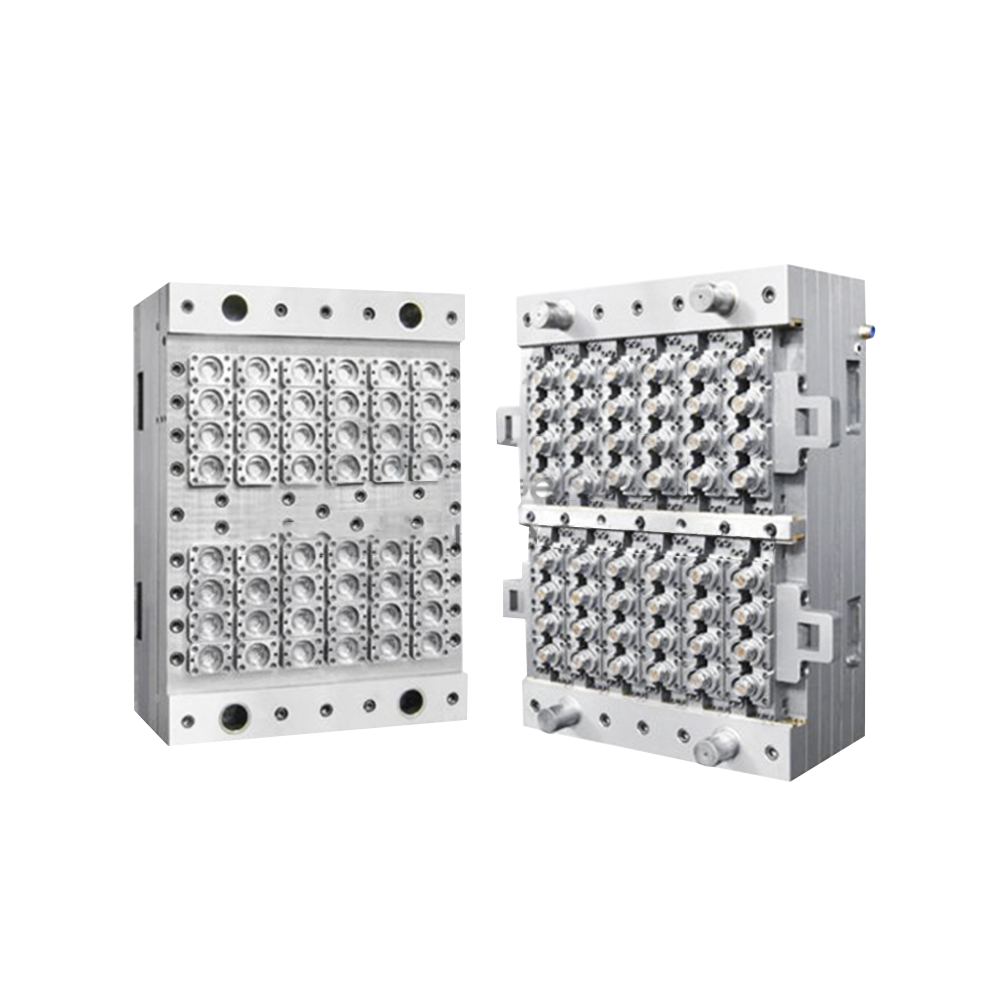

China Cheap PET Preform Injection Mold Blow Mould Factory

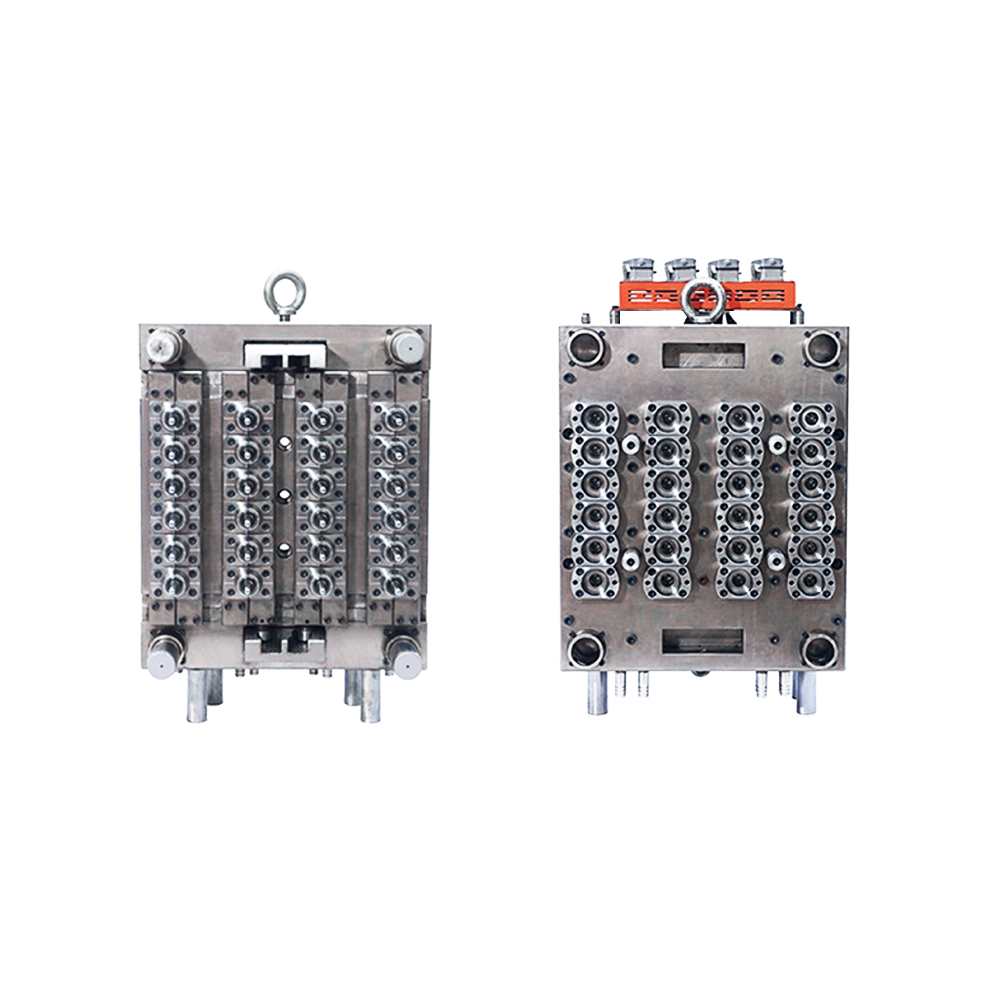

In the quest for sustainable development, the packaging industry has become a focal point for innovation. The role of China PET Preform Mold and Blow Mould Factory in this endeavor cannot be overstated. As the global demand for eco-friendly packaging solutions surges, these factories are at the forefront of creating molds that not only meet the functional needs of the market but also align with environmental standards.

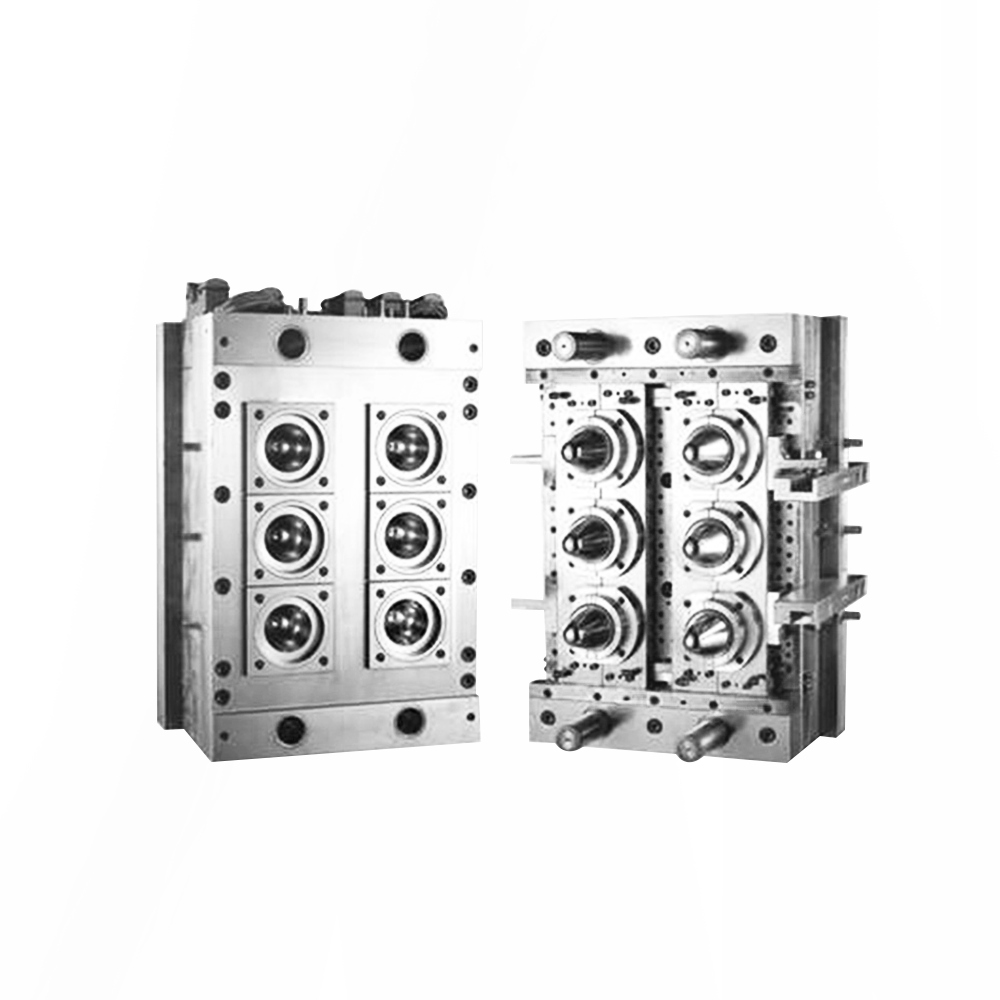

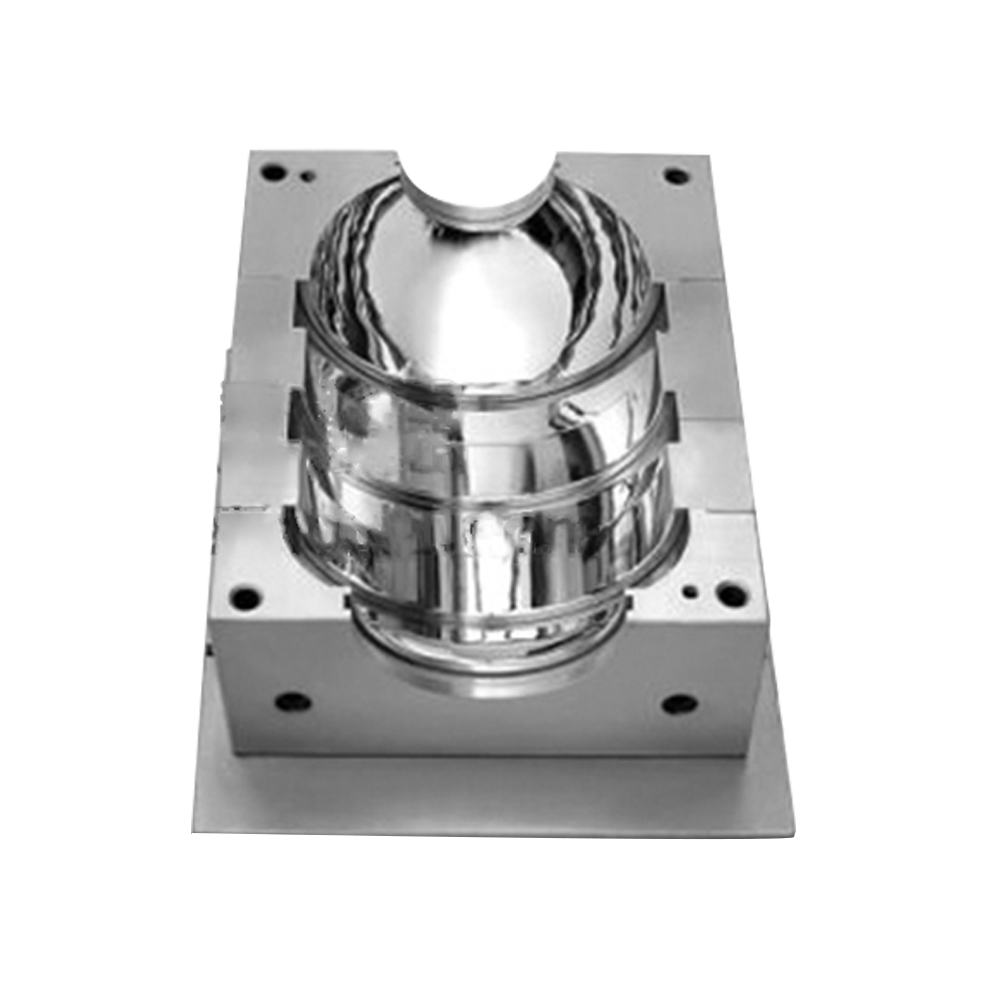

China PET Preform Molds are critical components in the production of PET bottles, which are widely used in the beverage industry. These molds are responsible for the initial shape and quality of the preforms, the precursors to the bottles. The precision and design of these molds directly impact the efficiency of the blow molding process, which in turn affects the overall environmental footprint of the packaging.

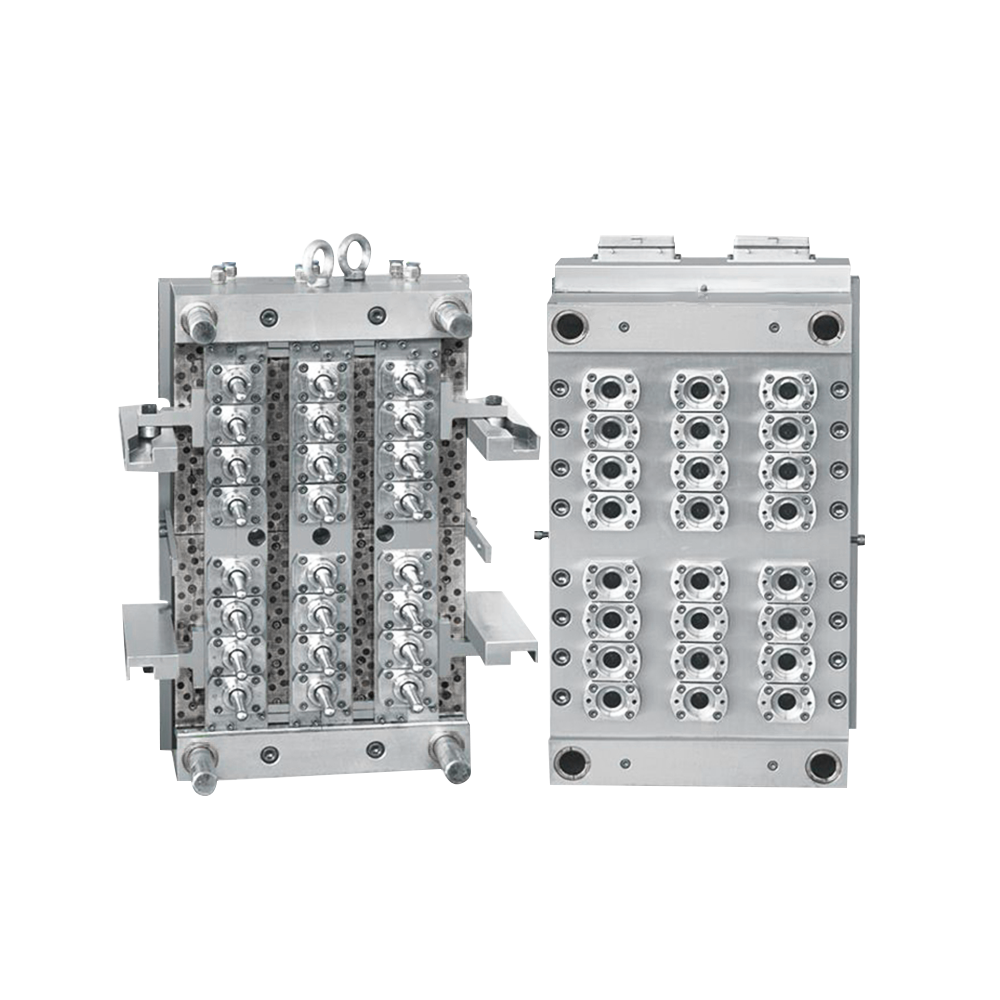

Blow Mould Factory in China has been investing in research and development to create more sustainable molds. These innovations include the use of materials with lower environmental impact, energy-efficient production processes, and designs that reduce waste. The factories are also exploring the use of recycled materials in the production of PET preform molds, further contributing to the circular economy.

The design of China PET Preform Molds is evolving to incorporate sustainability. Blow Mould Factories are focusing on creating molds that require less material, thus reducing the overall carbon footprint of the production process. Additionally, the molds are being designed to have a longer lifespan, reducing the need for frequent replacements and the associated waste.

Energy consumption is a significant factor in the environmental impact of any manufacturing process. Blow Mould Factory in China is implementing energy-saving technologies and practices. This includes the use of renewable energy sources, such as solar and wind power, to power their operations. The factories are also optimizing their production lines to reduce energy waste.

Waste management is another area where China PET Preform Mold and Blow Mould Factory are making strides. By reducing waste during the production process and implementing recycling programs, these factories are reducing their ecological impact. The use of advanced technologies allows for more precise cutting and shaping, which reduces material waste.

Lifecycle assessment is becoming an integral part of the design and production process in Blow Mould Factories. By evaluating the environmental impact of China PET Preform Molds from raw material extraction to end-of-life disposal, these factories can identify areas for improvement and implement strategies to reduce their ecological footprint.

China PET Preform Mold and Cheap PET Injection Molding are not operating in isolation. They are actively collaborating with suppliers, customers, and regulatory bodies to ensure that their products meet environmental standards. This collaborative approach fosters innovation and ensures that the entire supply chain is working towards a common goal of sustainability.

Investing in education and training is another way that Blow Mould Factory in China is promoting sustainability. By equipping their workforce with the knowledge and skills needed to produce eco-friendly molds, these factories are ensuring that their operations remain at the front of environmental responsibility.

The future of China PET Preform Mold and Blow Mould Factory in environmentally friendly packaging looks promising. With ongoing technological advancements, increased consumer demand for sustainable products, and a global shift towards greener practices, these factories are well-positioned to pioneer the way in the development of eco-friendly packaging solutions.

The role of China PET Preform Mold and Blow Mould Factory in environmentally friendly packaging is multifaceted and increasingly important. From innovative design to energy efficiency, waste reduction, and lifecycle assessment, these factories are playing a pivotal role in shaping a more sustainable future for the packaging industry. As the world continues to grapple with environmental challenges, the contributions of these factories will be instrumental in creating a greener and more responsible packaging ecosystem.

English

English عربى

عربى Español

Español