The Complete Guide to China Preform Mould's Manufacturing Process

Jun 28,2024

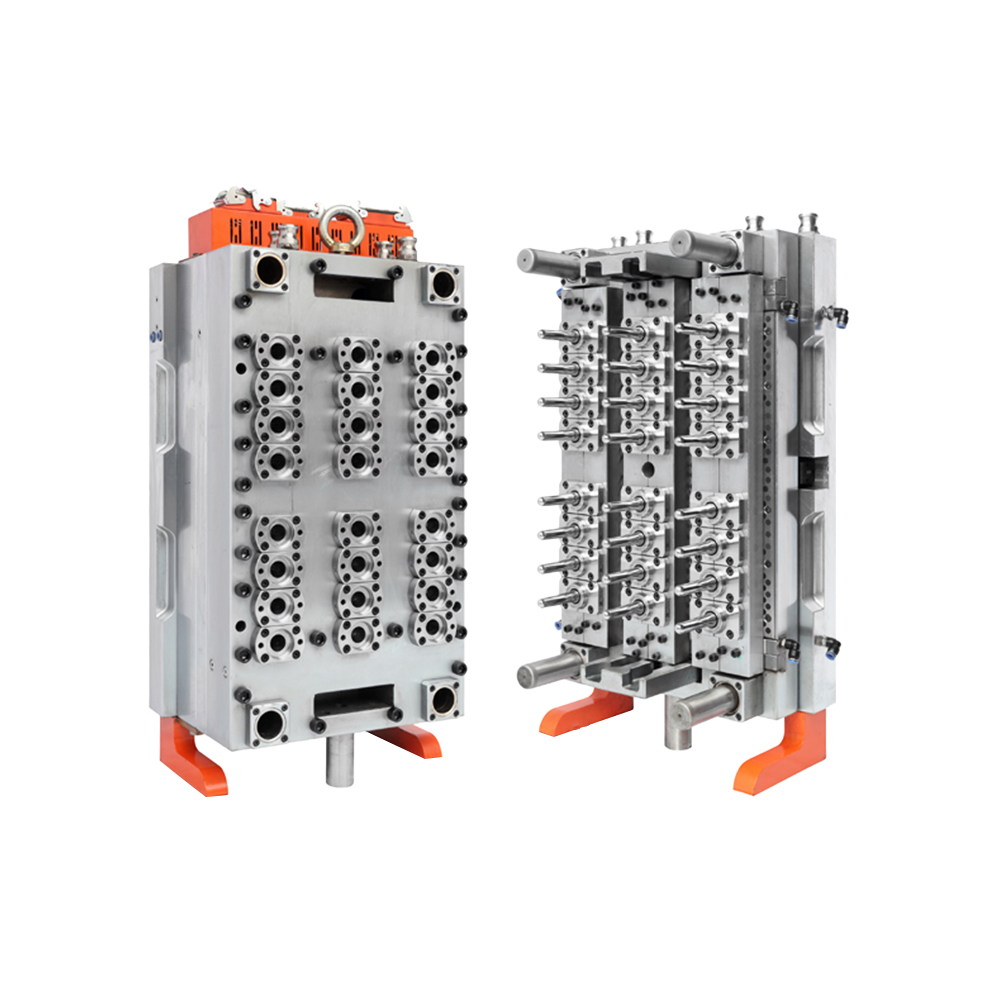

China OEM Preform Blowing Injection Mould Company

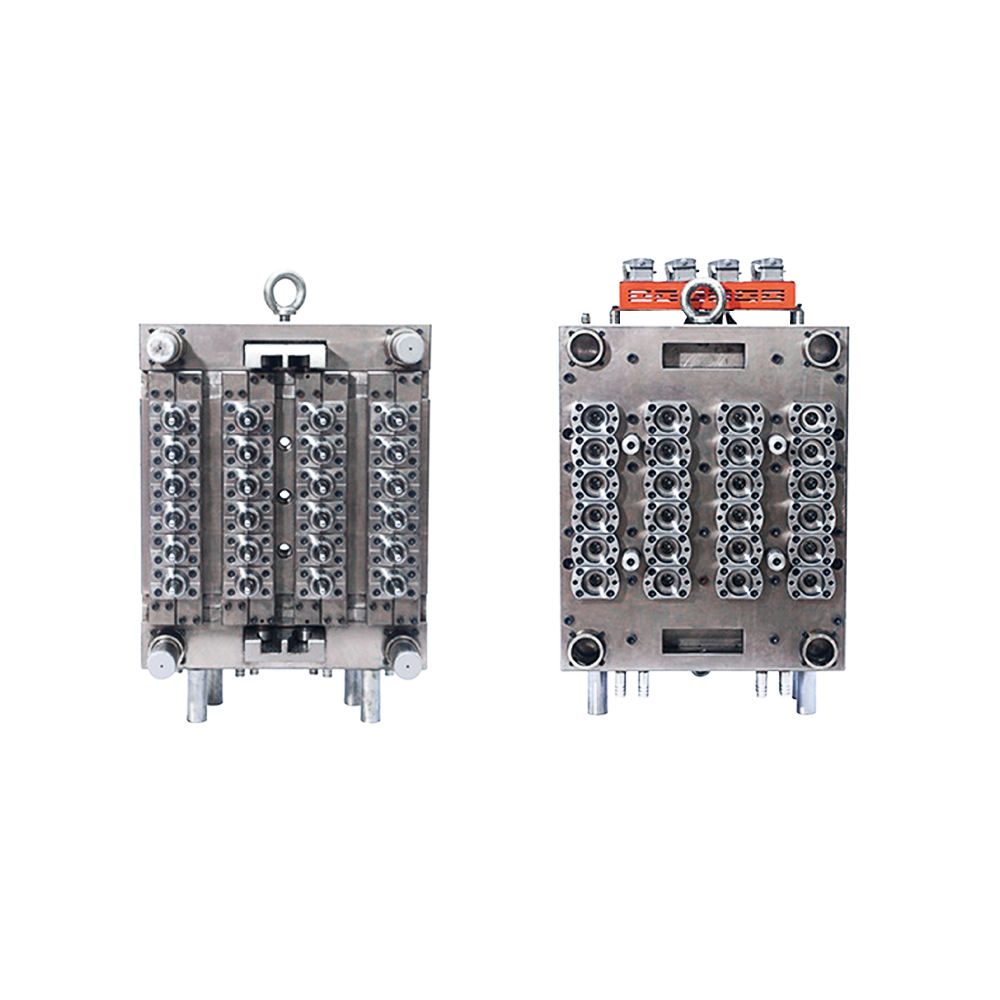

In the world of plastic manufacturing, China Preform Moulds play a pivotal role in creating high-quality preforms that are the foundation for producing bottles and containers. This comprehensive guide delves into the manufacturing process of OEM Preform Blowings, highlighting the steps, techniques, and considerations that make these moulds an essential component in the industry.

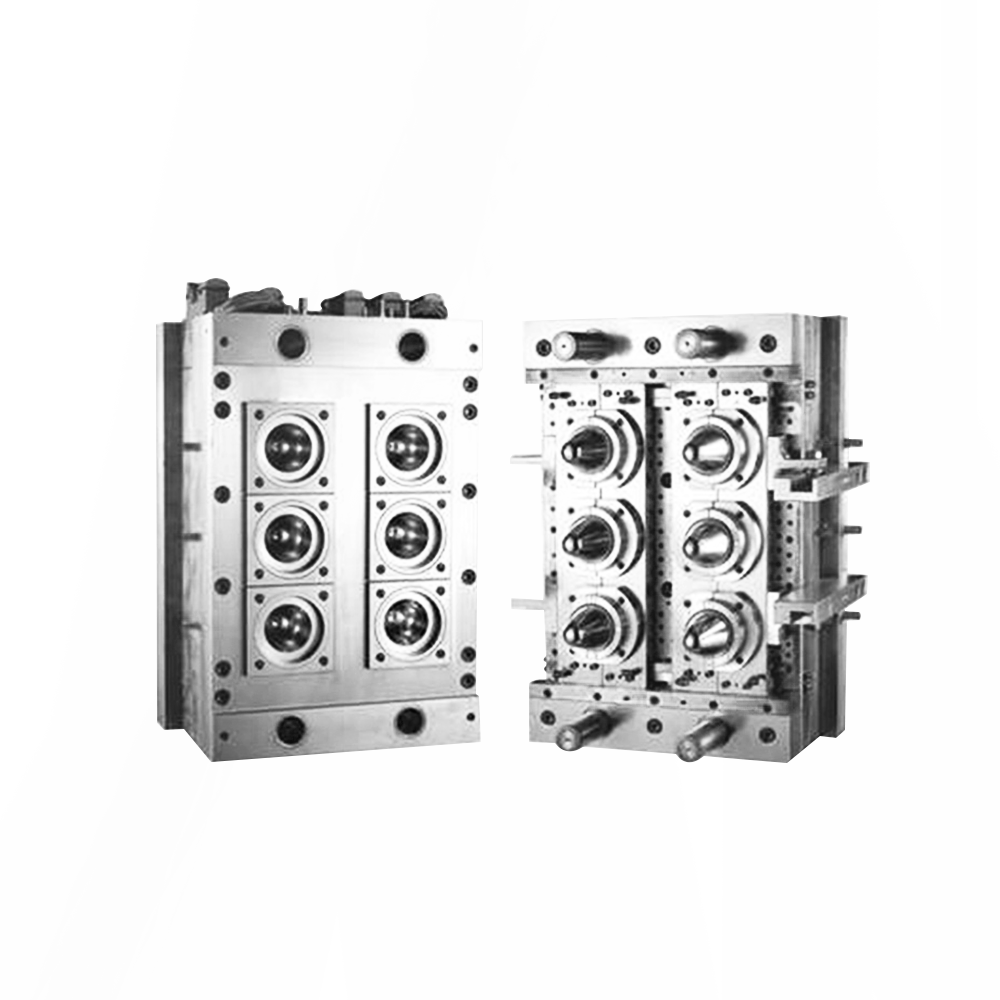

China Preform Moulds are precision tools designed to produce preforms, which are parison-shaped plastic forms that are later blown into bottles or containers. These moulds are crucial in the injection stretch blow moulding process, ensuring consistent quality and uniformity in the product.

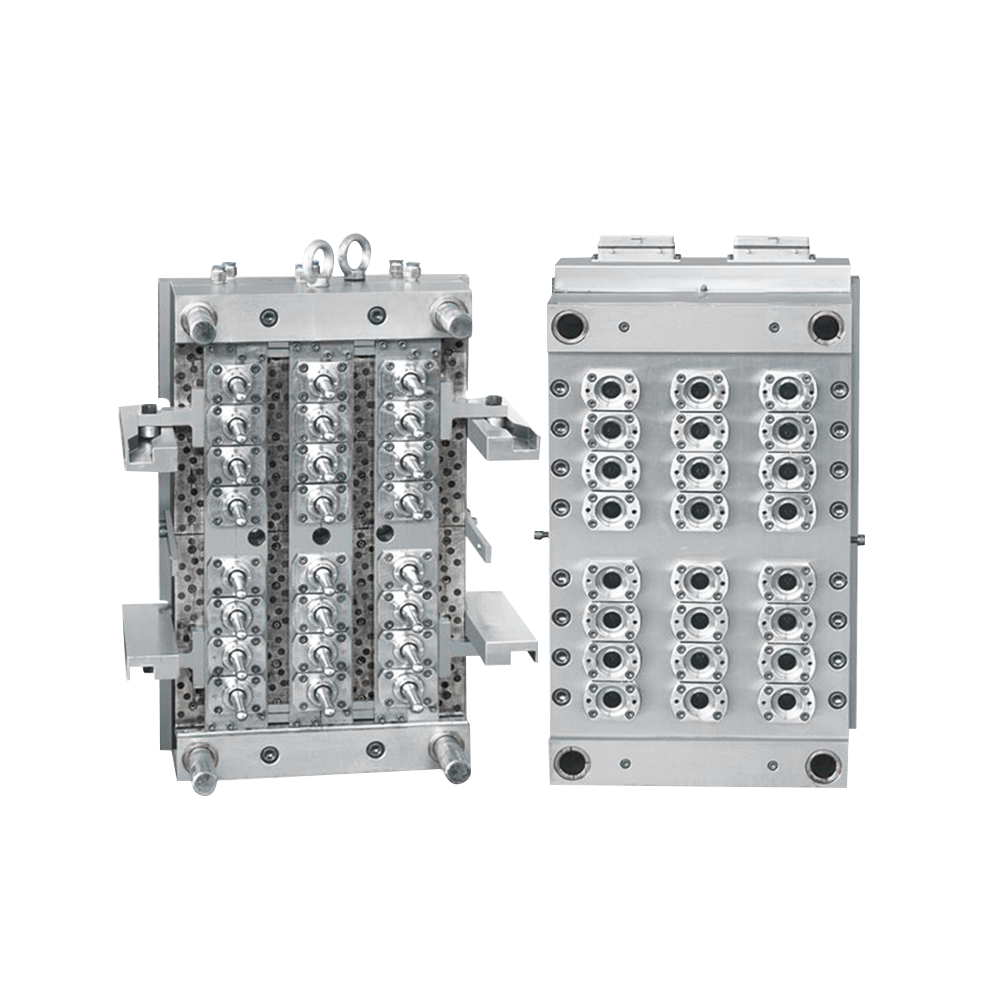

The manufacturing process of China Preform Moulds begins with selecting the appropriate materials. High-quality steel is typically chosen due to its durability, strength, and heat resistance. The choice of material directly impacts the mould's performance and longevity.

Before the actual manufacturing begins, the design and engineering phase is crucial. This involves creating detailed blueprints and specifications for the China Preform Mould, taking into account factors such as tolerances, dimensions, and the desired output of preforms. Advanced computer-aided design (CAD) software is often used to streamline this process.

Once the design is finalized, the machining and fabrication process commences. This involves cutting, shaping, and assembling the various components of the China Preform Mould. High-precision CNC (Computer Numerical Control) machines are commonly used to ensure accuracy and repeatability in the manufacturing process.

After the initial machining, the China Preform Mould undergoes heat treatment. This process hardens the mould, enhancing its durability and resistance to wear. It also helps to reduce internal stresses within the mould, ensuring a longer service life.

The next step in the manufacturing process is grinding and polishing the surfaces of the China Preform Mould. This is done to achieve the desired level of smoothness and precision, which is essential for producing high-quality preforms with consistent wall thickness and dimensional accuracy.

With the individual components of the Preform Injection Company prepared, they are assembled and integrated to form the complete mould. This involves carefully aligning and securing the components to ensure proper function and performance.

Before the China Preform Mould is deemed ready for use, it undergoes rigorous quality control and inspection processes. This includes checking for any defects, ensuring dimensional accuracy, and verifying that the mould meets the required specifications.

To further ensure the performance and reliability of the China Preform Mould, it is tested and validated under real-world conditions. This involves running trial production runs and evaluating the quality of the preforms produced.

One of the key strengths of China Preform Mould manufacturers is their ability to customize and adapt moulds to meet specific client requirements. This can involve adjusting the design, materials, or manufacturing process to accommodate unique needs or preferences.

China Preform Mould manufacturers are committed to continuous improvement, constantly refining their manufacturing processes and investing in new technologies to enhance the quality and efficiency of their products.

In today's environmentally conscious market, China Preform Mould manufacturers are also focusing on reducing the environmental impact of their operations. This can include using recycled materials, implementing energy-efficient practices, and designing moulds that produce preforms with reduced material usage.

This will likely involve further advancements in materials, design, and manufacturing techniques, as well as an increased focus on sustainability and environmental responsibility.

The manufacturing process of China Preform Moulds is a complex and intricate series of steps that combine precision, technology, and craftsmanship. By understanding and investing in this process, manufacturers can produce high-quality moulds that meet the diverse needs of the plastic industry. As the market continues to evolve, the role of China Preform Mould manufacturers will remain crucial in driving innovation and excellence in the production of preforms and containers.

English

English عربى

عربى Español

Español