Revolutionizing the Packaging Industry: The 5-Gallon Barrel Blow Mould

Jul 24,2023

Innovation has always played a pivotal role in the packaging industry, constantly seeking more efficient and sustainable solutions. One such remarkable advancement is the introduction of the 5-Gallon Barrel Blow Mould. This revolutionary process has transformed traditional packaging methods, providing improved functionality, cost-effectiveness, and environmental sustainability. This article explores the technology behind the 5-Gallon Barrel Blow Mould and its impact on the packaging industry.

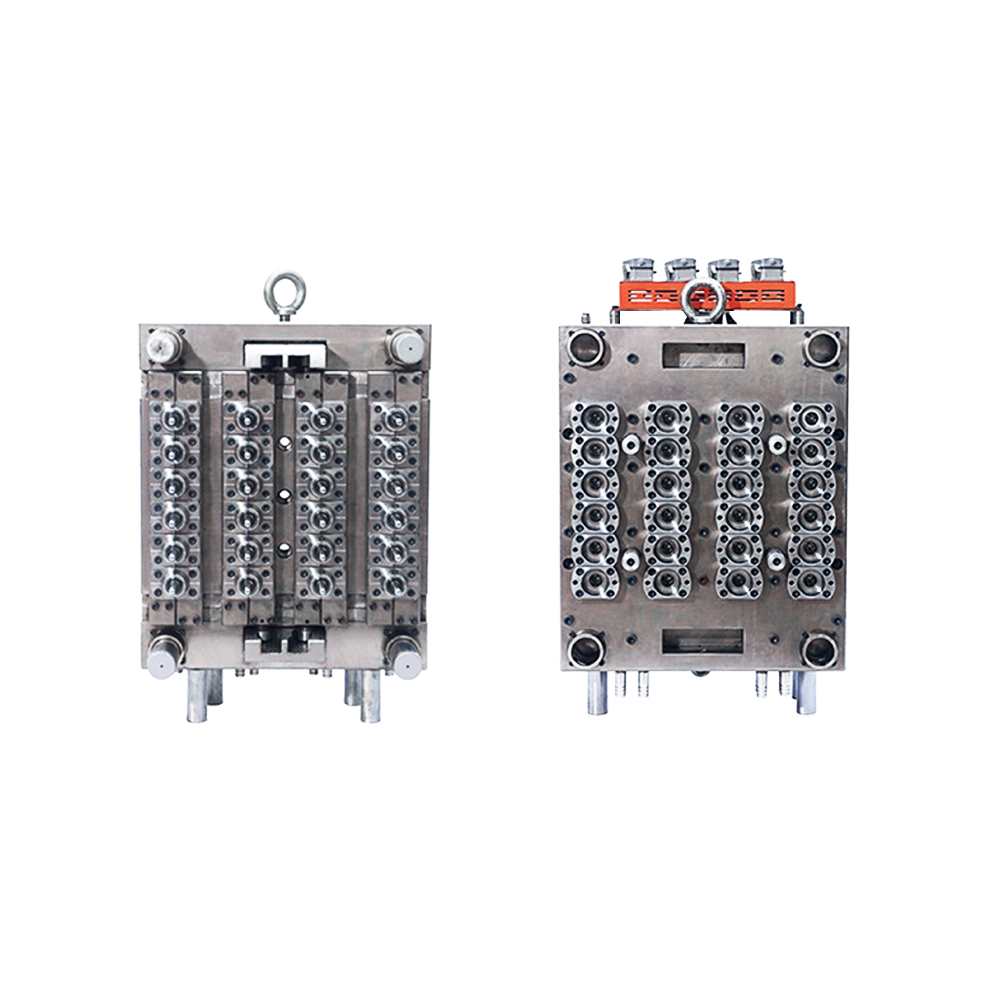

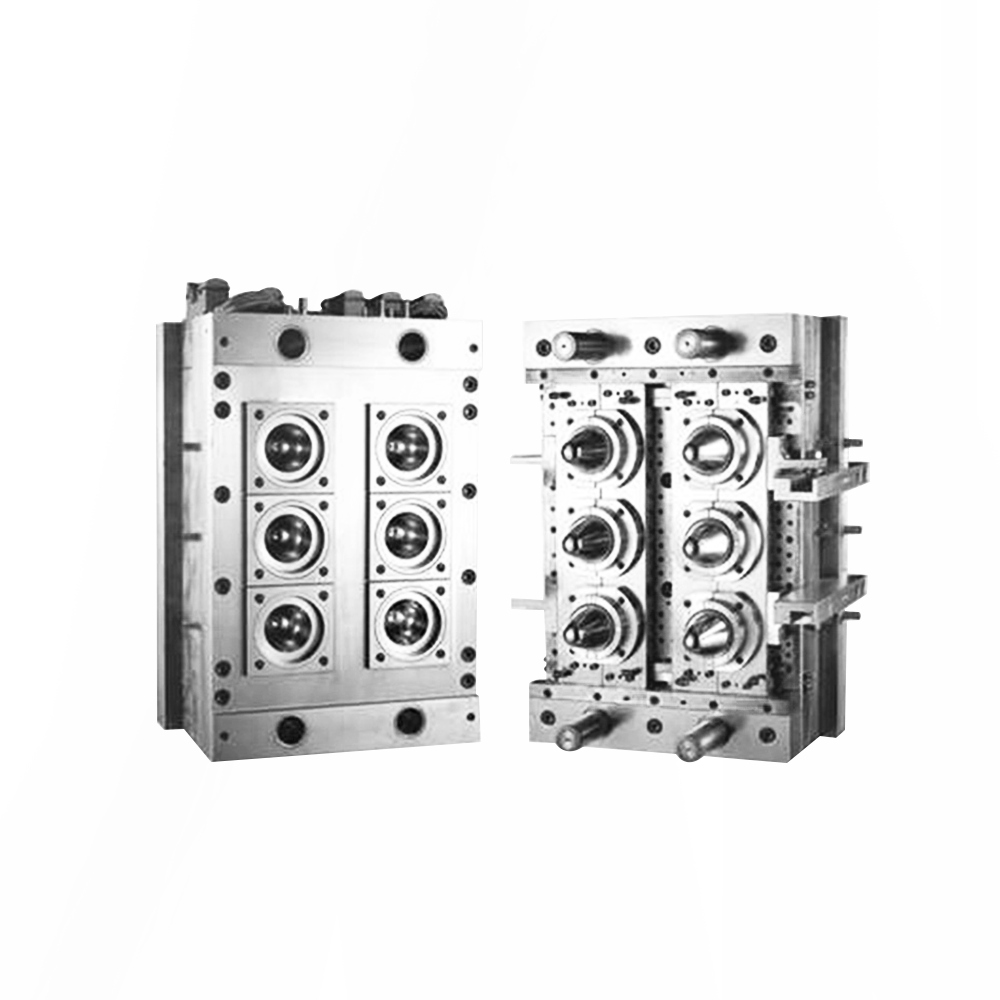

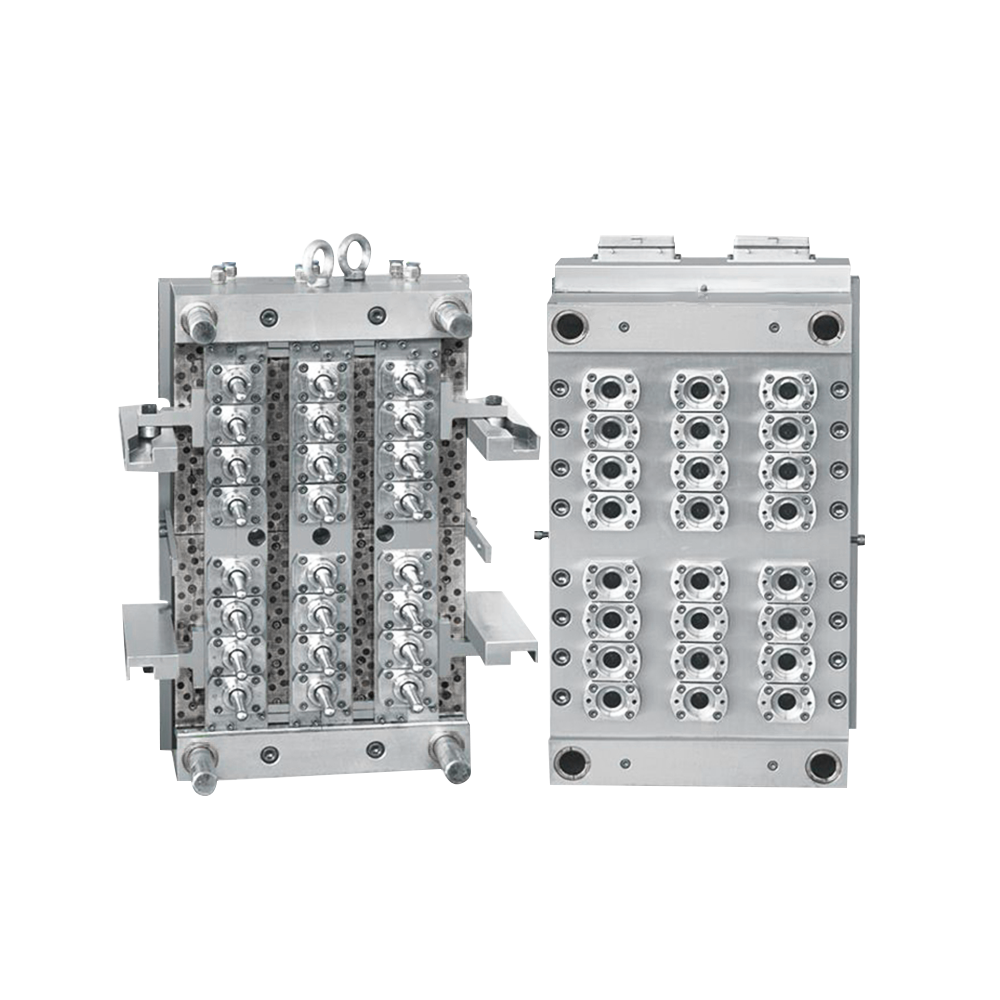

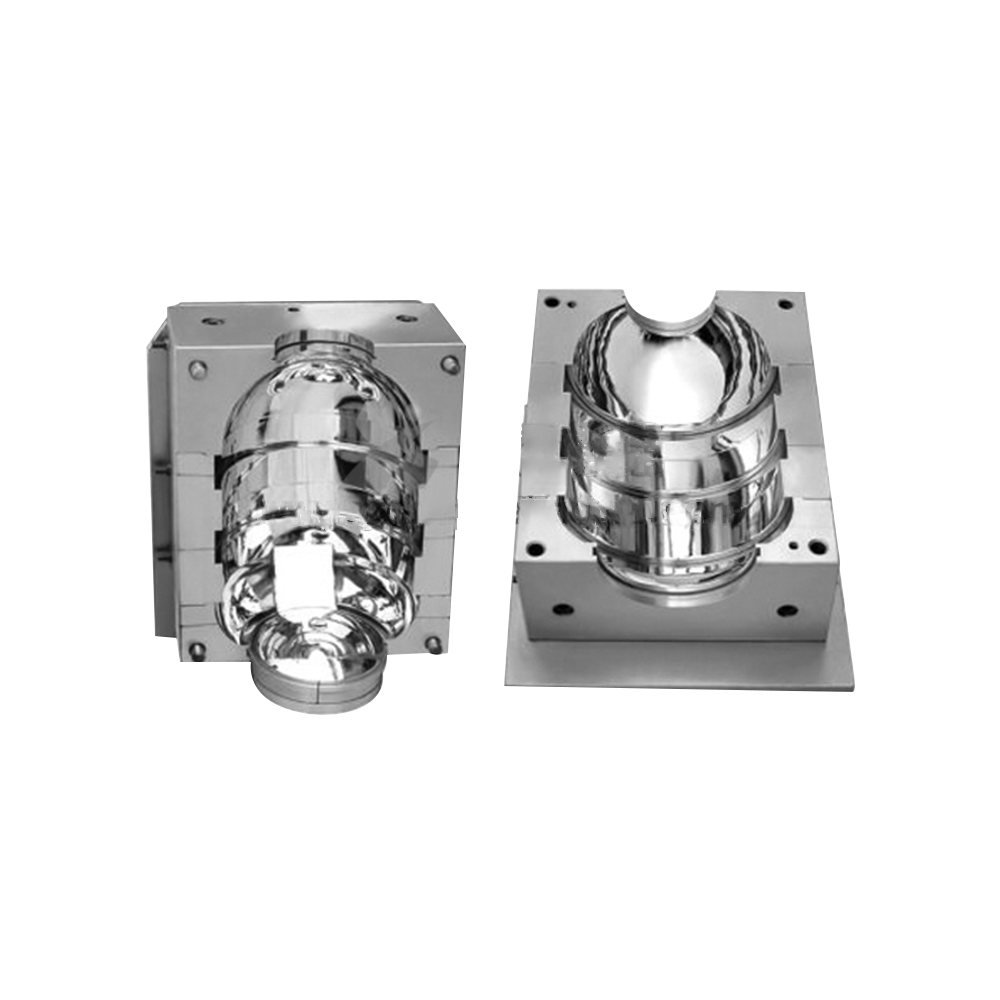

Understanding the 5-Gallon Barrel Blow MouldDefinition and FunctionalityThe 5-Gallon Barrel Blow Mould refers to a manufacturing process that creates large plastic containers typically used for the storage and transportation of liquids. This technology involves the expansion of heated plastic parisons within a mold through high-pressure air, resulting in the desired shape and size of the container.

Advantages over Traditional Packaging,Compared to traditional packaging methods, the 5-Gallon Barrel Blow Mould offers numerous advantages. It allows for quicker production, reduced material wastage, and enhanced product quality. Additionally, these barrels are stackable, making transportation and storage more efficient.

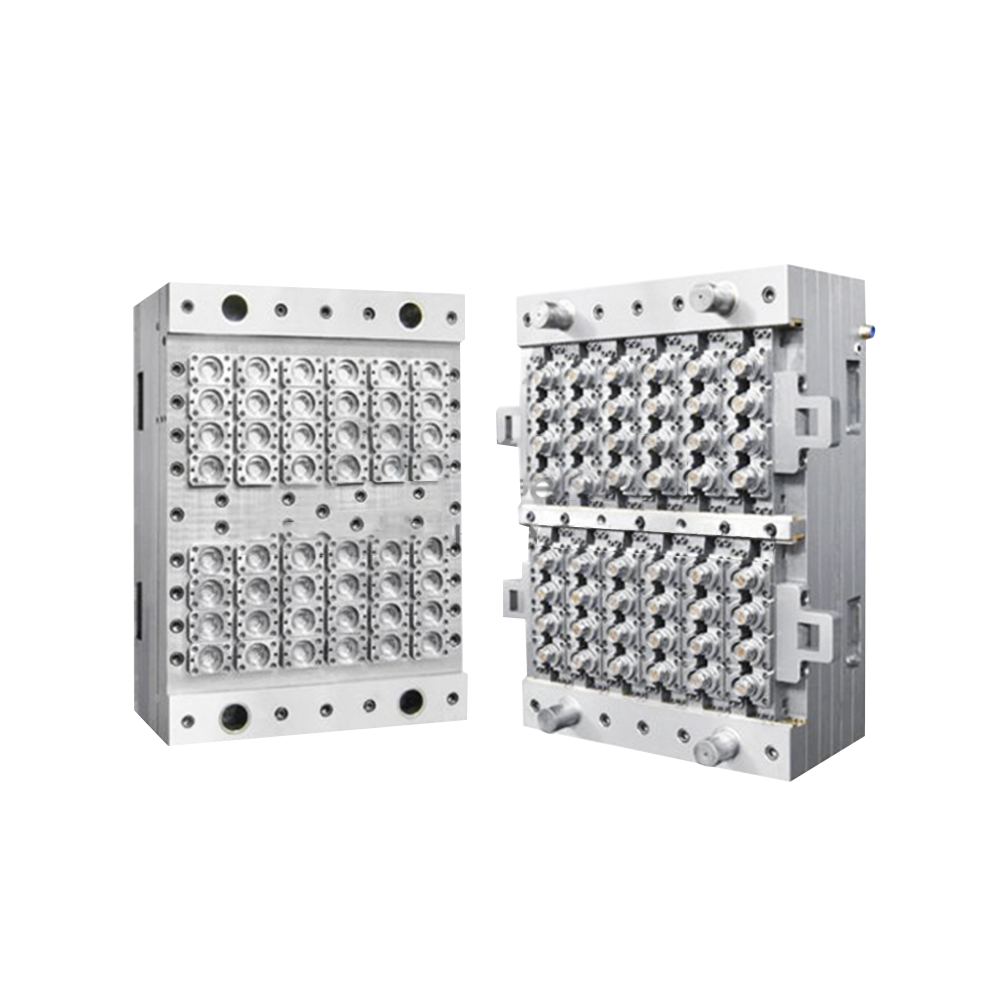

Process of the 5-Gallon Barrel Blow Mould,Designing the MoldThe first step in the process involves designing the mold to match the desired specifications of the 5-gallon barrel. This includes considering factors such as material thickness, shape, and strength.Heating and Parison ExtrusionNext, plastic resin pellets are heated to a molten state and passed through an extruder, which forms a molten plastic tube called a parison. The parison is then placed within the mold.

Stretch Blow Molding,The parison is clamped between the mold halves, and high-pressure air is blown into the parison, expanding it against the walls of the mold. This process stretches and shapes the plastic, giving it the desired form.

Cooling and Ejection,Once the plastic has cooled, the mold is opened, and the 5-gallon barrel is ejected. The excess plastic, known as flash, is usually trimmed to ensure a clean and finished product.

Environmental SustainabilityReduced Material Consumption,The 5-Gallon Barrel Blow Mould process significantly reduces material consumption compared to traditional packaging methods. The precise control over the plastic distribution within the mold ensures minimal wastage of raw materials.

Recyclable and Reusable,These barrels are typically made from high-density polyethylene (HDPE), a plastic that is easily recyclable and reusable. This material can be melted down and used for the production of new plastic products, promoting a more circular economy.

Applications and Market Impact

Versatile Applications,The 5-Gallon Barrel Blow Mould has found applications in various industries such as food and beverage, chemical, agricultural, and construction sectors. They are used for storage and transportation of liquids like water, chemicals, paints, and more.

Market Growth and Cost Efficiency,The introduction of the 5-Gallon Barrel Blow Mould has not only increased productivity but has also driven cost-effectiveness. The reduced material consumption and improved production efficiency have resulted in lower manufacturing costs, making the technology economically viable for businesses.

Conclusion

The 5-Gallon Barrel Blow Mould has undoubtedly revolutionized the industry. Its ability to produce durable, stackable, and environmentally friendly containers has made it an ideal solution for various sectors. As this technology continues to evolve, we can expect further advancements in terms of cost-efficiency, design capabilities, and overall sustainability, shaping the future of packaging.

English

English عربى

عربى Español

Español