Advancing Beverage Packaging: Revolutionizing Preform Moulds for Wide Mouth Bottles

Aug 01,2023

In today's competitive market, the beverage industry constantly seeks innovative packaging solutions to enhance the consumer experience and optimize production efficiency. Two groundbreaking advancements in this realm are the 85mm 47g Wide Mouth Preform Mould and the Custom 28g Preform Mould. These cutting-edge mold technologies have revolutionized wide-mouth bottle production, offering increased versatility, precision, and cost-effectiveness. This article explores the features and benefits of these perform molds and their impact on the beverage packaging industry.

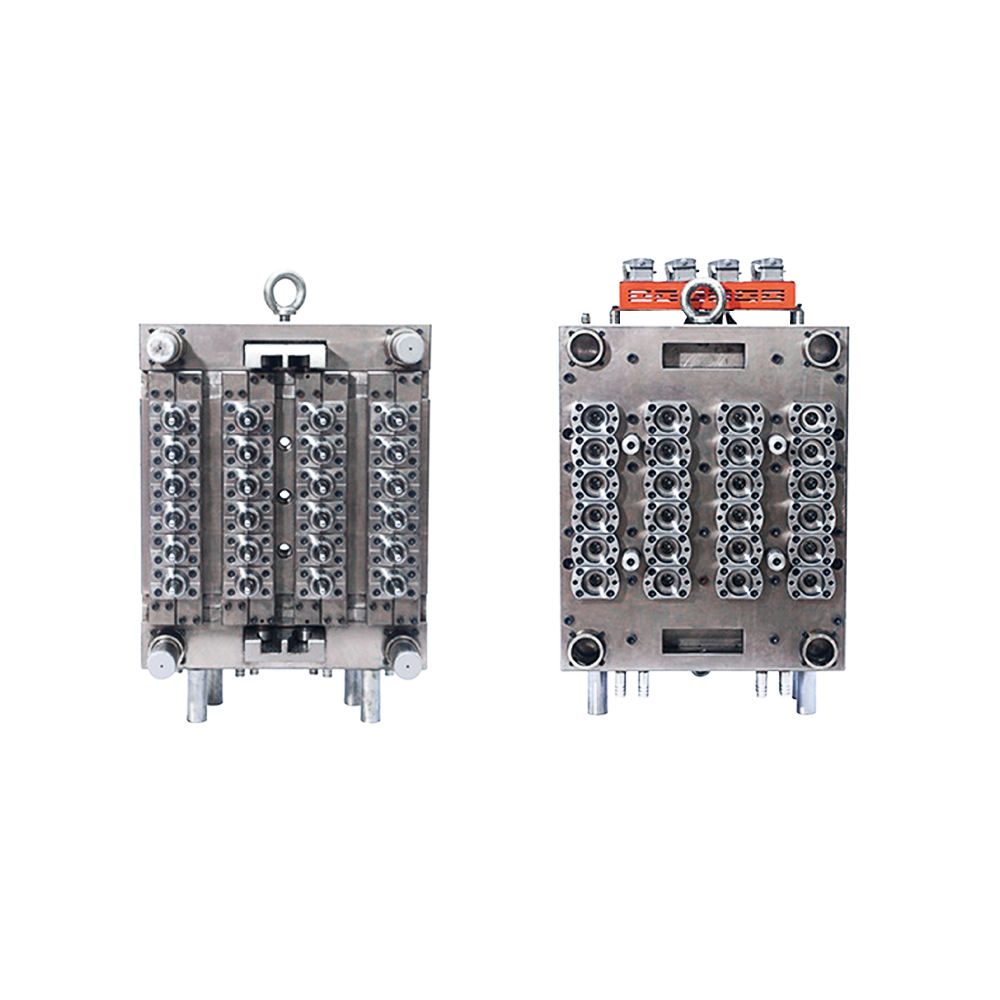

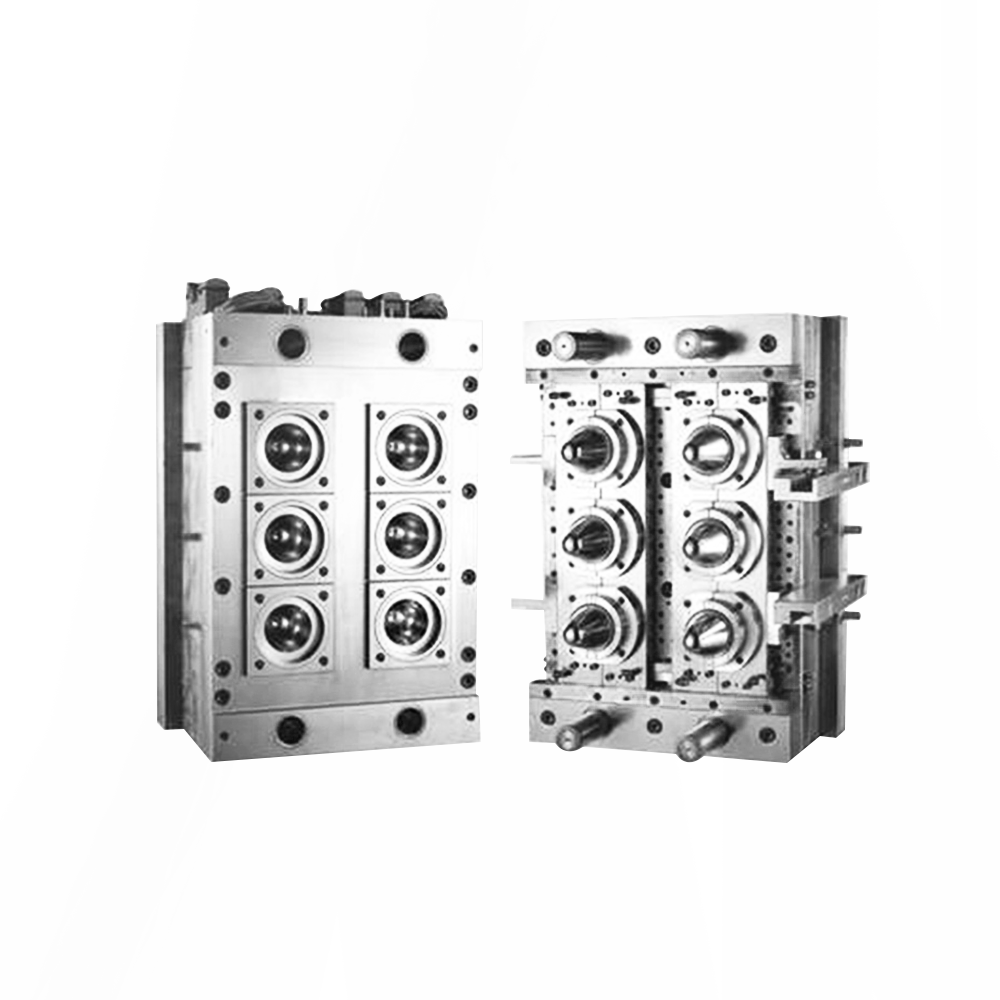

Unveiling the 85mm 47g Wide Mouth Preform Mould, Definition, and Versatility: The 85mm 47g Wide Mouth Preform Mould refers to a molding technology designed specifically for producing wide-mouth bottle preforms. These forms are widely used in the beverage industry for packaging products such as juices, energy drinks, and ready-to-drink beverages. The wide mouth allows for easy pouring and consumption.

Enhanced Design and Functionality; Compared to traditional narrow-mouth preforms, the wide-mouth variant provides several advantages. Its larger opening facilitates easier filling and dispensing of beverages and accommodates the addition of ingredients, such as fruit pieces or ice cubes. Moreover, the wider neck diameter allows for a better pouring experience, reducing spills and inconvenience.

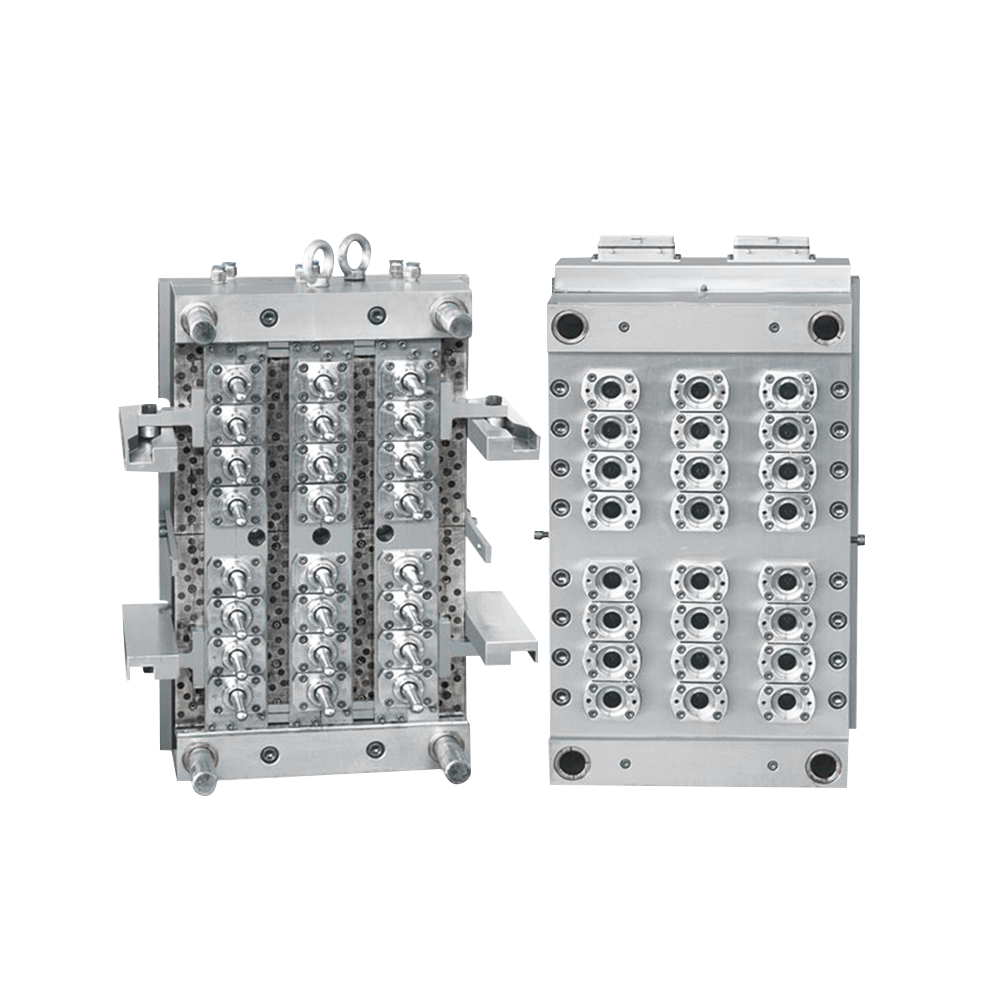

Exploring the Custom 28g Preform Mould, Tailored to Specific Requirements: The Custom 28g Preform Mould is a groundbreaking technology that allows manufacturers to design and produce preforms according to their specific requirements. This includes customization of preform weight, neck diameter, and overall dimensions, enabling companies to meet their unique packaging needs efficiently.

Benefits of Customization: By utilizing the Custom 28g Preform Mould, beverage companies can optimize packaging design, performance, and brand identity. Customization provides the flexibility to create preforms that align with the desired product attributes, aesthetics, and market positioning.

Process of Wide Mouth Preform Moulding: Injection MoldingThe process of manufacturing wide-mouth preforms begins with injection molding. Plastic resin pellets are melted, injected into a preform mold cavity, and rapidly cooled to form the desired shape.

Stretch Blow Molding: Once the preforms are ready, they undergo the stretch blow molding process. This involves heating the preform and then inflating it using high-pressure air to shape it into the final container.

Advantages and Impact on the Beverage Packaging Industry: Improved Production Efficiency

The introduction of these innovative preform mold technologies has significantly enhanced production efficiency in the beverage packaging industry. The precise control over the preform design allows for optimized material usage, resulting in reduced waste and cost savings.

Consumer Experience and Market Appeal: Wide-mouth bottles adhere to the growing consumer demand for convenience and functionality. The effortless pouring and easy insertion of ingredients provided by wide-mouth bottles enhance the overall consumer experience and increase market appeal.

Sustainability and Environmental Considerations: The customization aspect of these preform molds enables companies to manufacture lightweight preforms, reducing material consumption and overall packaging waste. Additionally, the materials used, such as PET (polyethylene terephthalate), are recyclable, contributing to a more sustainable packaging solution.

Adoption and Future Prospects: Industry Adoption and Market Growth: The adoption of the 85mm 47g and Custom 28g Preform Moulds has gained traction in the beverage industry, driven by their numerous benefits and the evolving demands of consumers. The market for wide-mouth bottles is projected to grow due to the rising popularity of functional and specialty beverages.

Future Innovations and Packaging Trends: As technology advances, further innovations in preform molding are expected to address emerging trends in beverage packaging. These may include improved barrier properties, tamper-evident features, and smart packaging solutions.

The 85mm 47g Wide Mouth Preform Mould and Custom 28g Preform Mould have brought significant advancements to the beverage packaging industry, reshaping the way wide-mouth bottles are produced. Their versatility, customization capabilities, and the resulting consumer experience have positioned them as integral components in the evolution of packaging. As the demand for efficient and sustainable packaging solutions continues to grow, further enhancements and innovations can be anticipated in the performing moulding sector.

English

English عربى

عربى Español

Español