The Advantages and Importance of preform mould

Mar 31,2023

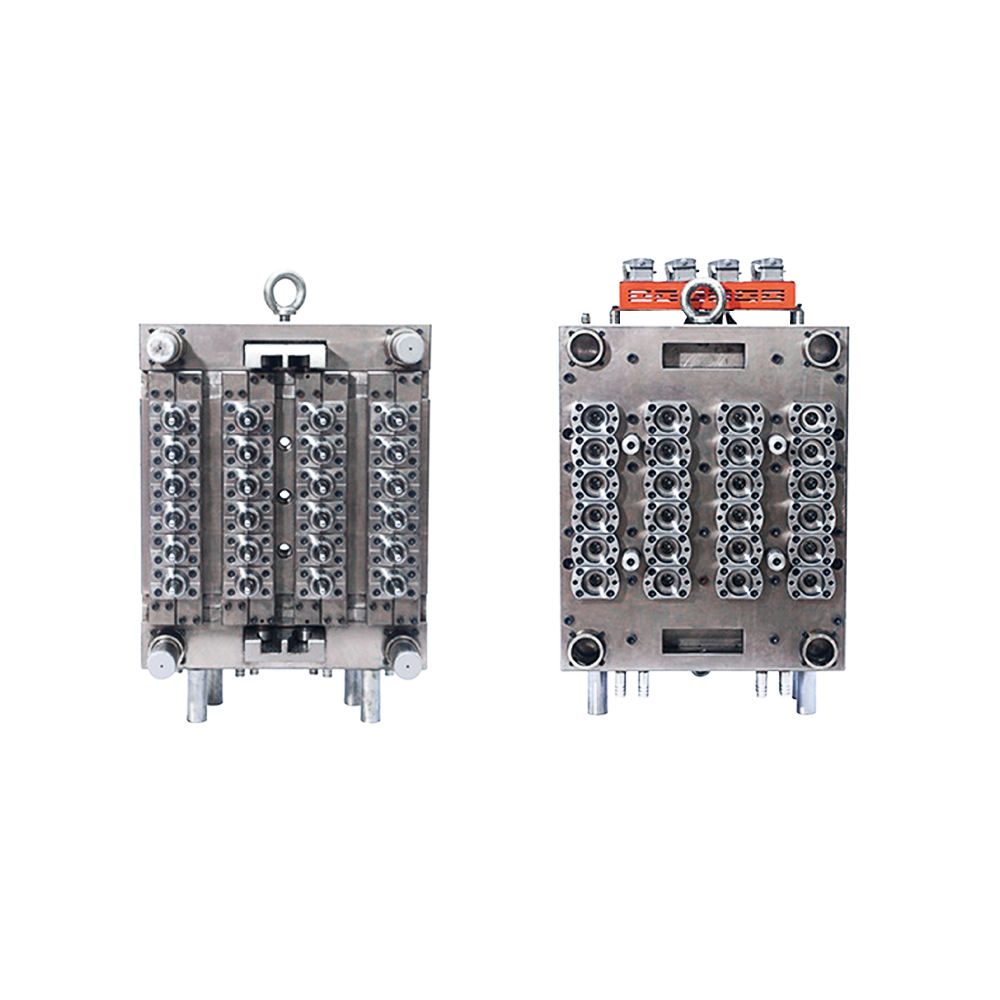

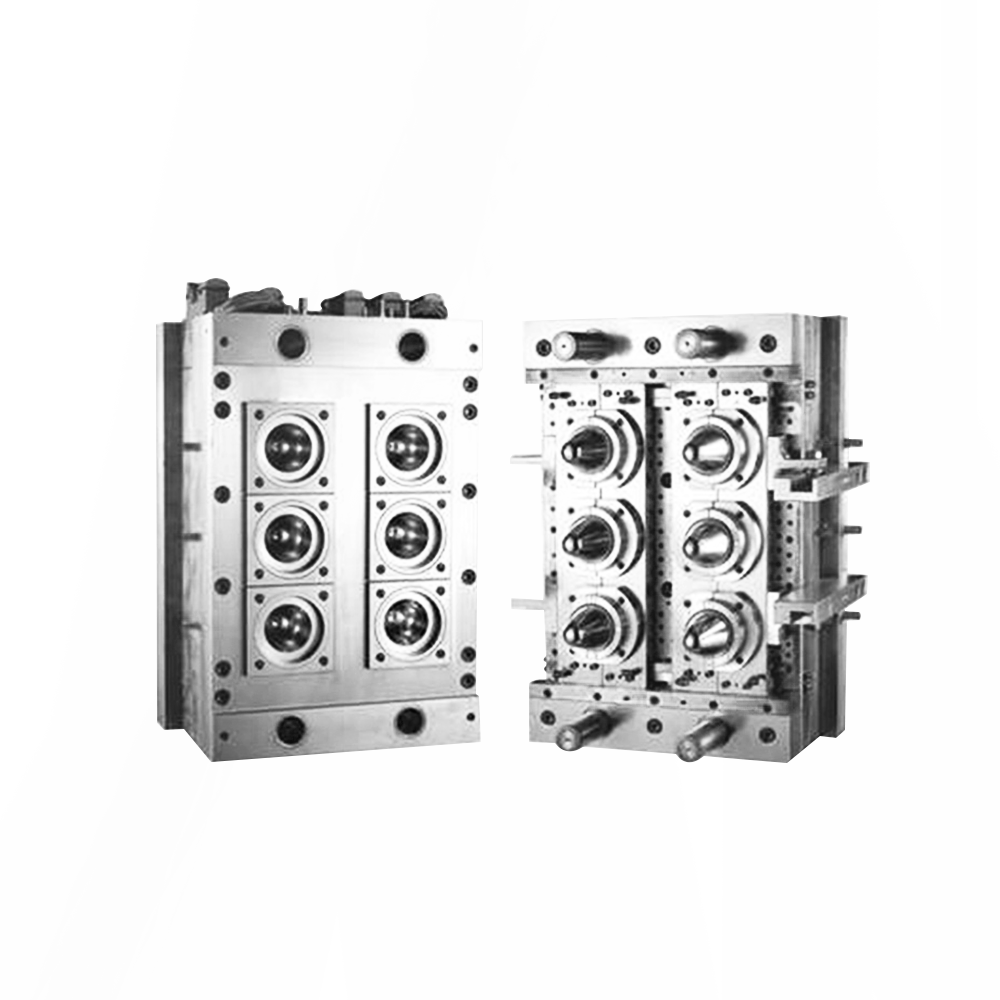

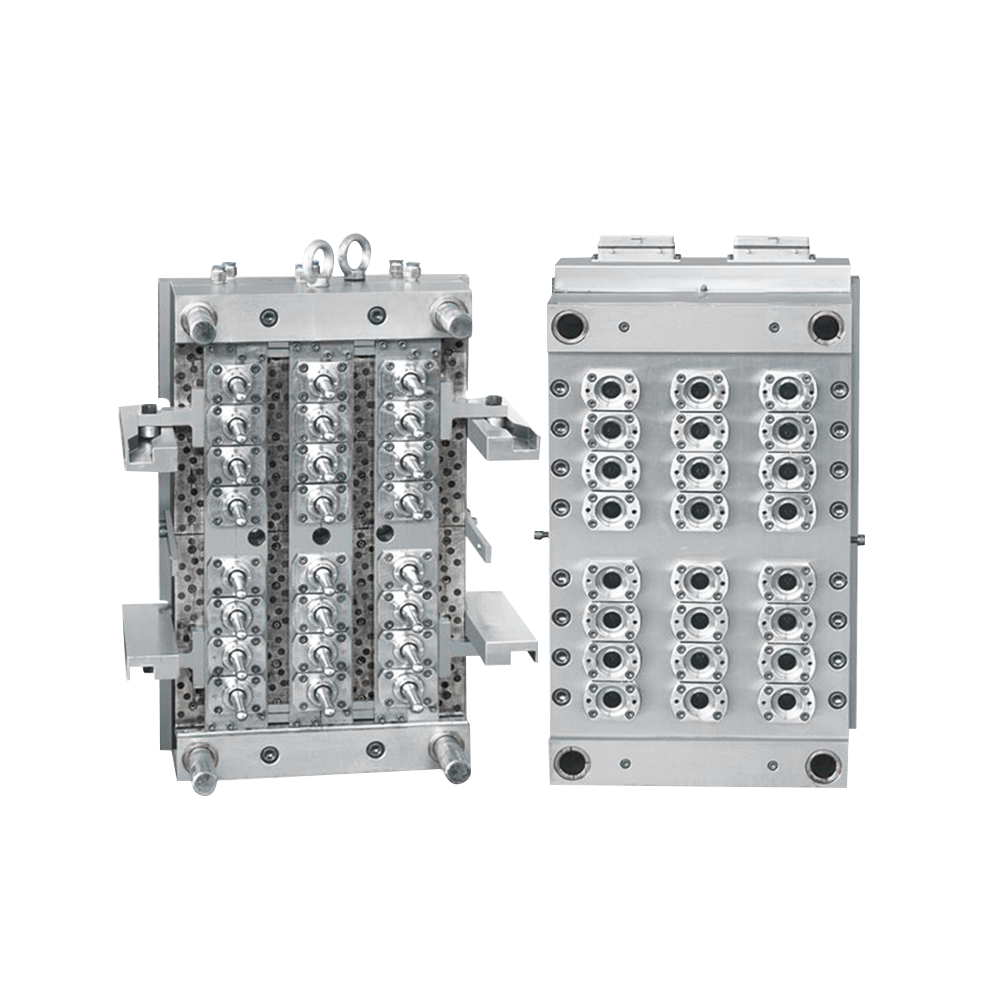

A preform mould is a type of plastic injection mould used to make bottles and other shapes. Its functionality depends on its design, but it must be durable and reusable.A preform mould can be made from various materials, such as PP and PET. The material chosen is based on the needs of the client.Advantages.A preform mould is a type of plastic injection mold that is used to produce bottles and other products. It is designed to be strong, lightweight and able to withstand heat. The design of a preform mould is important because it determines the quality and durability of the final product.A good preform mould can make the process of producing a bottle easier and more efficient. It will also reduce the cost of the manufacturing process.These moulds can be made from different materials, depending on the needs of the manufacturer. They can be made from metal, like steel, or they can be made from a resin.Some of the most common types of preform moulds include self-lock and non-self-lock. Self-lock preforms are perfect for smaller quantities, while non-self-lock ones are ideal for large quantities.The material that is used to make the preform mold is very important. It should be durable and easy to clean. It should also have a high level of strength and be competitively priced.

Another important feature of a preform mould is its flexibility. It must be able to adapt to different machines and be compatible with all kinds of plastics.Using the right kind of preforms is essential for the production of plastic bottles. This is because the bottles can have many different functions and features.It is important to know that a dry preform will not behave the same as a wet one during reheating and blow molding, so it is essential to use the right materials for each step of the process.To ensure that your product reaches the market in the best possible condition, you need to select the most durable preform mold available. The material should be able to withstand a range of temperatures, including high heat and low temperature.The preform mould is also a great choice for recycling. It is an environmentally friendly option that can help you save money and energy.The preform moulds are a reliable and efficient way to produce bottles. They are very easy to work with and can be used to make a variety of different bottles.Importance.A preform mould is an important tool in any industry. It helps to create various plastic products, such as bottles. It is also a good way to save money on production costs.A preform mould can be made from different materials, depending on your needs. It should be lightweight, durable, and resistant to corrosion. It should also be able to withstand high pressures.

Some of the most common types of preform molds include self-locking and non-self-locking moulds. The former is suitable for small-scale batches of preforms, while the latter is ideal for larger production runs.In terms of material, a preform mould can be made from a variety of plastics, including PVC and PET. These materials are light and durable, and can be recycled easily.However, these materials can be susceptible to damage from physical or chemical vapor deposition. This is why it is important to choose a high-quality preform mould that will stand up to heavy use.A preform mould should be designed to ensure that it can withstand the pressures of injection molding machines. It should also be sized correctly to ensure that it is suitable for the product that it is meant to make.The most commonly used plastics for a preform mould are PET and polyethylene. These materials have several advantages over other types of plastics, such as the ability to be recycled and being non toxic.Moreover, they are lightweight and have a low carbon footprint. They are also easy to clean and can be reused for many purposes.

Another factor that affects the quality of a preform mould is the material that it is made from. The best material for a preform mould is PET, as it has excellent hardness and anti-rust properties.It is also a popular choice for a preform mould, as it has a long lifespan and is easy to clean. It is also very cost-effective and has minimal downtime compared to other mould types.A preform mould can be used for making a wide range of plastic products, such as bottles and jars. They are a good option for creating unique and attractive items that people will want to buy. They are also highly flexible, which is a good thing for businesses that need to make a variety of items.Requirements.A preform mould is a piece of plastic which is created using injection moulding. It is often used in the manufacture of plastic bottles, vases and other containers.A high-quality preform mould should be made of a lightweight, durable and corrosion resistant material. It should also be able to withstand pressures and provide an attractive finish. It should also be easy to clean and maintain.

There are many different types of preform moulds available. Some are specifically designed to handle a particular type of resin. Others are more general in nature.They can be made from various materials such as aluminum, brass, plastic, plexiglass and wood. Some are even made from combinations of these materials.Generally, the best preform moulds are made of durable plastic with a high level of strength. This is because it will be subjected to intense heat and high pressures throughout the production process.A top-quality preform mould should be able to withstand these pressures and prevent leakage from occurring. This will increase the efficiency of your manufacturing process.Another benefit of a preform mould is that it is often recyclable. This makes it a great option for those looking to reduce their carbon footprints while still producing quality products.Some of the other features which make a preform mould worthy of its name include the fact that it can be easily cleaned, and that it is durable enough to withstand high temperature changes and corrosion. This is especially important when it comes to thermoplastics.In conclusion, a good preform mould can make all the difference in your product’s success. It will help you create a quality bottle or container, which is a big deal in the plastics industry. In addition, it will save you time and money in the long run.

English

English عربى

عربى Español

Español