Bottle Cap Mould: The Unseen Essential of Everyday Life

Aug 14,2023

Bottle caps are as ubiquitous as the very air we breathe. They seal our favourite beverage, safeguard the purity of medicinal syrups, and are tossed away thoughtlessly once their purpose is served. Have you ever paused and pondered how these mundane yet vital items come into existence? If yes, allow us to take you on a stimulating journey through the world of bottle cap moulds.

Now and then, inventions or advancements in technology take place that completely transform the way we live and operate. The development of the bottle cap mould is one such innovation that, although often unappreciated, has significantly influenced the packaging industry. Leading to the construction of varied and efficient bottle caps, this device is integral to ensuring the safe and effective storage of countless goods.

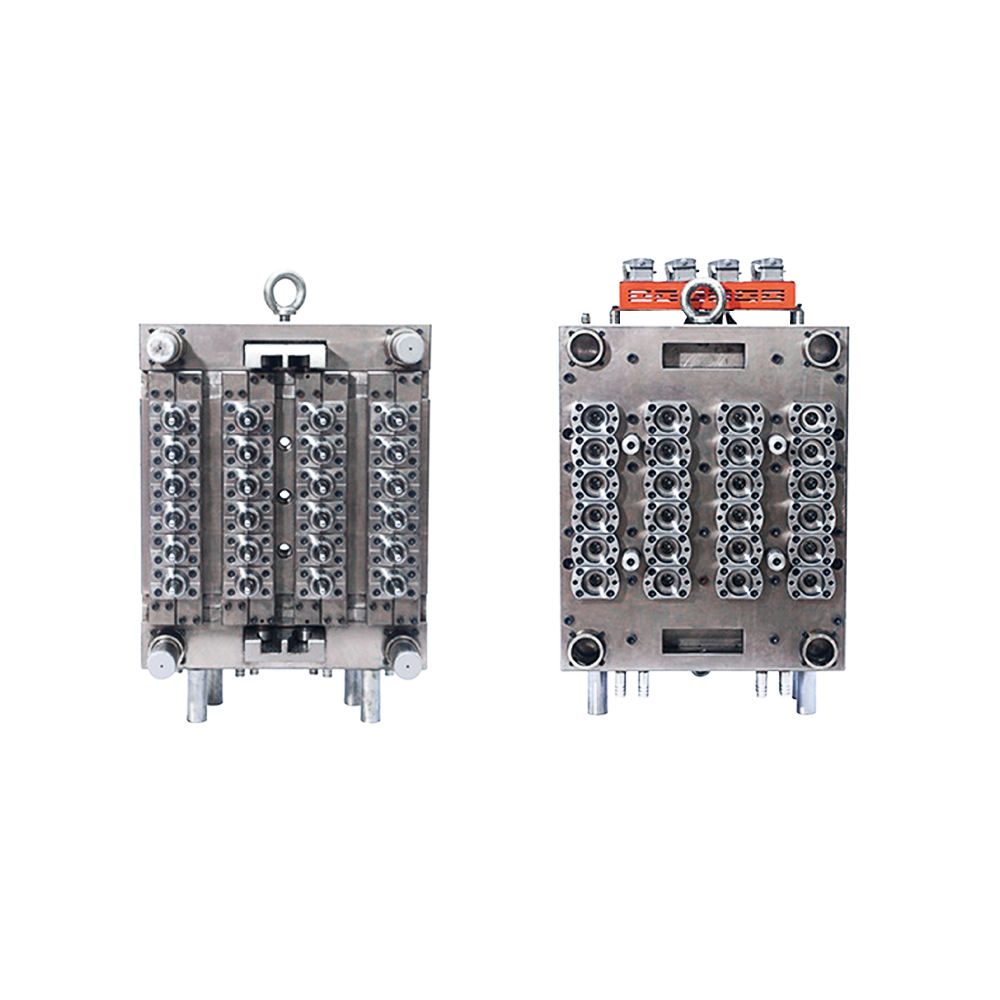

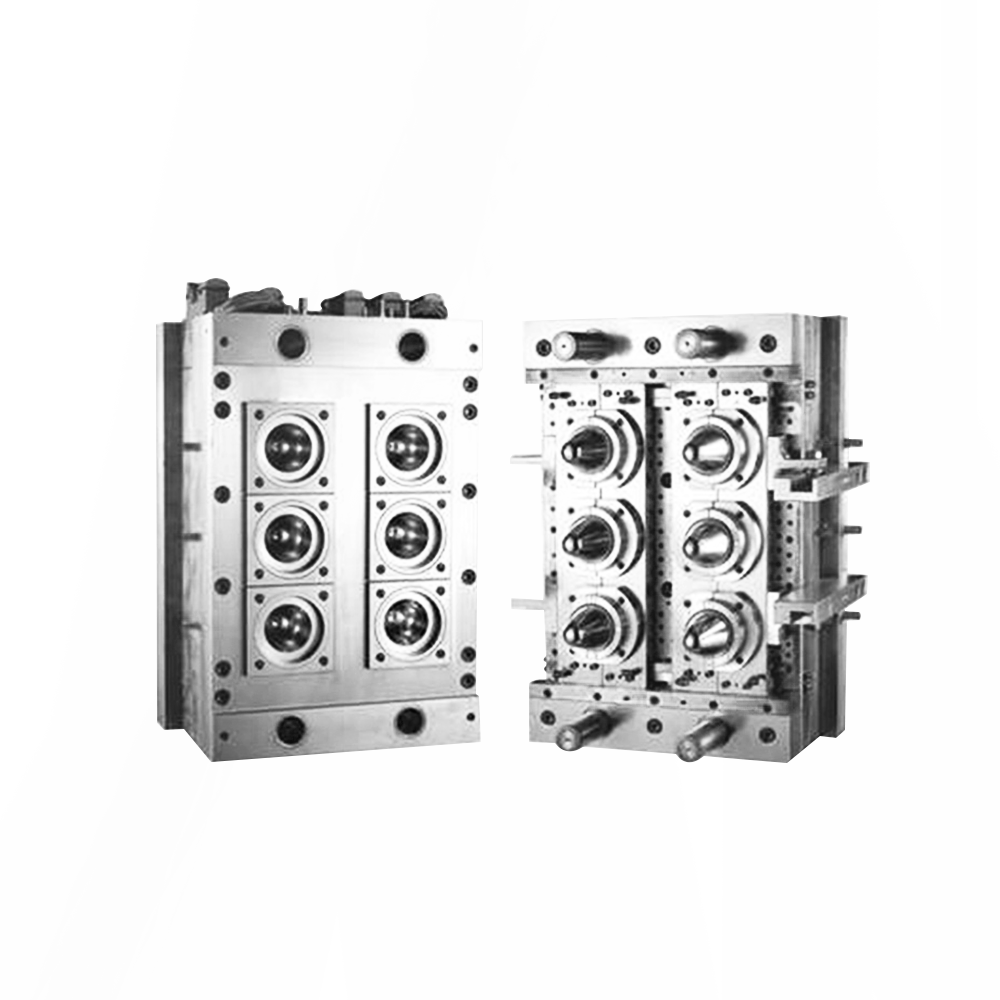

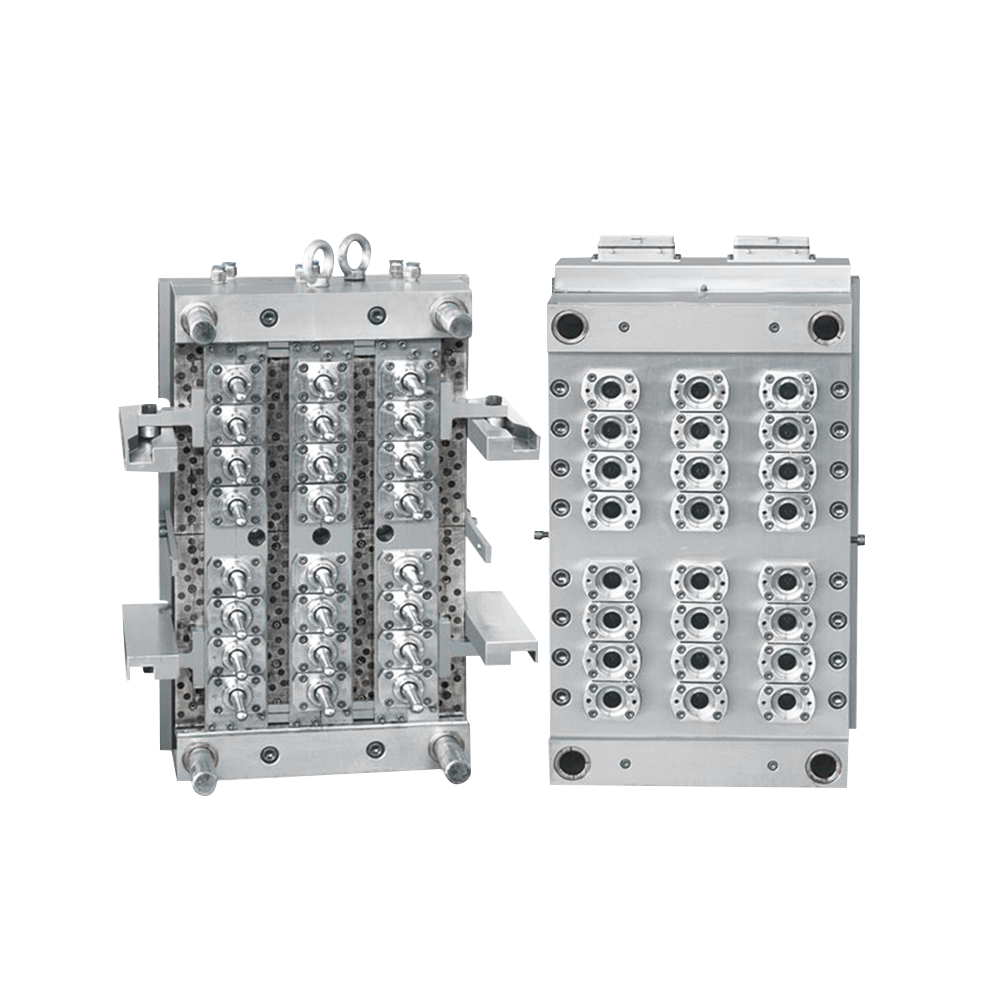

A bottle cap mould renders the ideal solution for creating accurate and identical caps every time. Designed using computer-aided design (CAD) software, these moulds are highly detailed and designed explicitly for each cap’s specifications. Material inputs primarily include metals like stainless steel and aluminium for their durability and resistance to corrosion.

Producing a standard bottle cap involves a procedure called injection moulding. In this process, the raw material, primarily plastic resin, is heated until it becomes liquid. It is then injected into the mould under high pressure. After cooling, the mould is opened, freeing the solidified and perfectly shaped bottle cap. The beauty of this process is the level of precision and consistency it offers - each cap, though mass-produced, is virtually identical to the last.

One notable frontier of development for bottle cap moulds lies in the evergreen goal of sustainability. Increasing environmental awareness means that there is an urgent need to develop moulds that can accommodate more eco-friendly materials without compromising on quality and durability. Research is ongoing, with various promising breakthroughs seen in the usage of biodegradable materials for bottle caps.

Lately, customization is becoming a significant trend in the bottle cap mould industry. Enabling manufacturers to produce caps with unique designs and logos, the advancement in mould technology is driven by the marketing and branding needs of companies. As a result, we see various clever and creative uses of bottle caps, from promoting a brand to expressing individuality.

Overall, the bottle cap mould has carved a significant niche in the manufacturing industry. From creating airtight seals for your fizzy drinks to contributing to unique marketing strategies, these moulds are integral, though unperceived parts of our daily lives. The next time you unscrew a bottle cap, remember the meticulous process behind its creation. The bottle cap mould is truly an unsung hero in the manufacturing world, silently ensuring that our beverages remain fresh and our medicines are uncontaminated.

However, as with all unsung heroes, the bottle cap mould operates best when unnoticed. As consumers, our primary interaction is with the final product - the bottle cap, not the mould. But it's essential to remember that without these precision-crafted moulds, our day-to-day interactions with various products would look drastically different, and likely less efficient. The bottle cap mould, while mundane to some, is a fascinating subject that unveils the impressive attention to detail in the manufacturing process. As we twist off a cap to enjoy a refreshing drink or to access life-saving medicine, let's spare a thought for the remarkable piece of technology that makes it all possible.

In conclusion, the bottle cap mould, an unseen linchpin in our daily lives, compels us to appreciate the sophistication of modern manufacturing and the untold efforts behind ordinary items. Next time you encounter a bottle cap, take a moment to acknowledge the intricate process and remarkable technology that moulded it.

English

English عربى

عربى Español

Español